Bob in SF

Member

Hi Erik - I ordered mine last week (non-express) - should arrive this week - will post first efforts this weekend.

Best regards, Bob

Best regards, Bob

Any updates about this engraver? Those of you who bought it, how is it performing so far? Does it require a lot of learning? I don't have any engraving knowledge/experience but I'm seriously considering buying one of these.

Sorry I've not had much of a chance to experiment with mine yet--just got a laptop set up for the shop to run it. All I can say at this point is that it works, and was quite easy to set up. I plan to turn some hard wood spindles to test for the best font style/size on a curved surface. Will post as soon as I have results to share. Regards, Michael

Sorry I've not had much of a chance to experiment with mine yet--just got a laptop set up for the shop to run it. All I can say at this point is that it works, and was quite easy to set up. I plan to turn some hard wood spindles to test for the best font style/size on a curved surface. Will post as soon as I have results to share. Regards, Michael

Thanks for the reply. I'm not tech savvy, would it be hard to operate for someone like me?

Sorry I've not had much of a chance to experiment with mine yet--just got a laptop set up for the shop to run it. All I can say at this point is that it works, and was quite easy to set up. I plan to turn some hard wood spindles to test for the best font style/size on a curved surface. Will post as soon as I have results to share. Regards, Michael

Thanks for the reply. I'm not tech savvy, would it be hard to operate for someone like me?

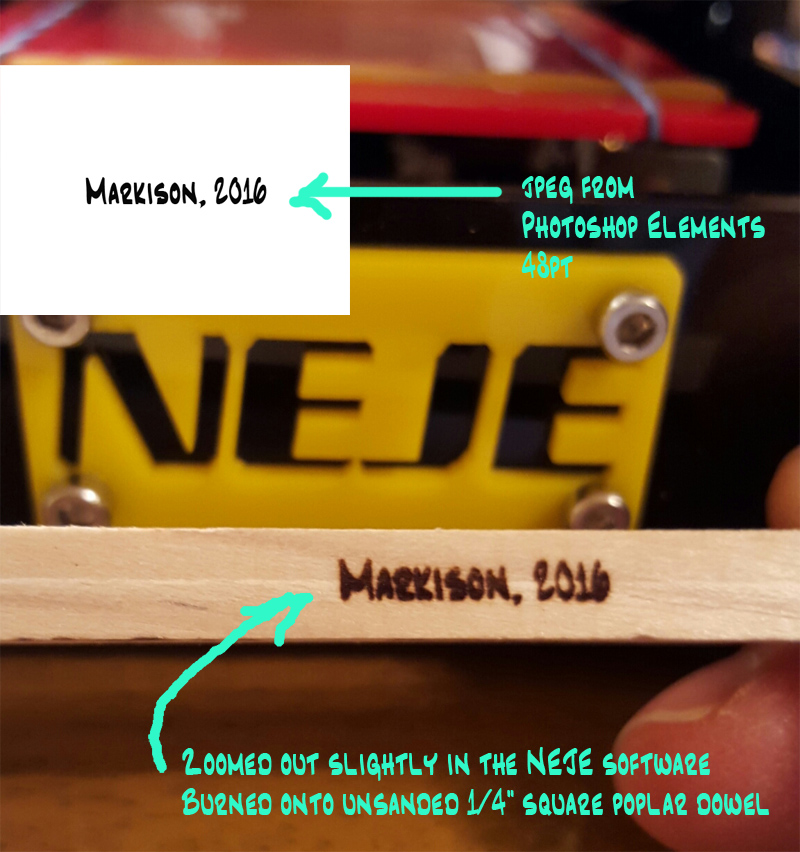

I don't think you'd have a problem. You install the software that comes with the engraver, plug in the two USB cables and it is usable. You'll need some sort of image manipulation software. I use Photoshop Elements, but any would do.

I'm looking forward to having time to fine-tune my text engraving this weekend. I made a pen holder to sit on the bed this morning (drew it in Sketchup and printed it on the Makerbot Replicator).

I will be setting up for an "official" engraving later tonight. Haven't been active since Friday (threw my back out).

I like the V-block idea. I just use some folded paper towel to hold the rounded pen blank.

Sorry I've not had much of a chance to experiment with mine yet--just got a laptop set up for the shop to run it. All I can say at this point is that it works, and was quite easy to set up. I plan to turn some hard wood spindles to test for the best font style/size on a curved surface. Will post as soon as I have results to share. Regards, Michael

Thanks for the reply. I'm not tech savvy, would it be hard to operate for someone like me?

I don't think you'd have a problem. You install the software that comes with the engraver, plug in the two USB cables and it is usable. You'll need some sort of image manipulation software. I use Photoshop Elements, but any would do.

I'm looking forward to having time to fine-tune my text engraving this weekend. I made a pen holder to sit on the bed this morning (drew it in Sketchup and printed it on the Makerbot Replicator).

LOL Make your V block on a 3d replicator? That's a hoot! Didn't it take a few hours? I've done some assembled pens, and the clip can get in the way in a V block. I added a notch on one side to clear the clip. But, I made the block on that old fashioned table saw and used a chisel, of all things, to make the notch.

has anyone had a chance to try these on an acrylic blank yet?

Be careful running something like a sharpie in the laser. If it has a PVC body, you will be making chlorine gas. Highly corrosive and deadly! PVC= polyvinyl chloride

Be careful running something like a sharpie in the laser. If it has a PVC body, you will be making chlorine gas. Highly corrosive and deadly! PVC= polyvinyl chloride

Mine arrived this afternoon - cute - simple setup and operation - won't have time to fiddle with it until this weekend - but pleased with first burn onto an unsanded 1/4" square dowel from Lowe's - not regretting purchase so far - has potential - pic: Best regards - and will keep you posted - Bob

Mine arrived this afternoon - cute - simple setup and operation - won't have time to fiddle with it until this weekend - but pleased with first burn onto an unsanded 1/4" square dowel from Lowe's - not regretting purchase so far - has potential - pic:

Best regards - and will keep you posted - Bob

I am curious about this working on steel, as there seems to be mixed and conflicting information available.

Do any of you current owners have the ability/willingness to test this? If it does work, that will definitely seal the deal for me.

Getting there - quickly (and partially) turned this hard wood blank (on a 7mm tube) - sanded with 600 grit - Lithos Pro 48pt typeface in Photoshop, saved as jpeg - burned at a speed of 60 with a little fan blowing smoke away:

- Bob

(for $87.00, it works surprisingly well)

1st hardwood slimline - burned outside since there was a nice breeze for smoke relief (obvious benefit of burn-anywhere portability) at a speed of 60 after sanding to 600 grit followed by 2 applications of Myland's Sanding Sealer. Finish = 3 applications of Myland's High Friction Polish. So far, so good - and grateful to Michael for starting this thread:

Best regards - Bob

(more tests ahead this weekend)

which one have you guys been ordering? the link that was initially posted takes me to a model that you configure before adding it to the cart.

which one have you guys been ordering? the link that was initially posted takes me to a model that you configure before adding it to the cart.

This one: NEJE DK-8-KZ 1000mW Laser Engraver Printer-97.41 and Free Shipping| GearBest.com

$87.99 with free standard shipping, an extra $8.00 for expedited.

Thanks everyone for sharing their experiences so far. Here is one I did last night. The first "official" engraving for a customer. Also my first attempt at multi-line engraving. All alignments I did were by eye.

which one have you guys been ordering? the link that was initially posted takes me to a model that you configure before adding it to the cart.

This one: NEJE DK-8-KZ 1000mW Laser Engraver Printer-97.41 and Free Shipping| GearBest.com

$87.99 with free standard shipping, an extra $8.00 for expedited.

OK, for some reason I thought you guys were getting the open looking frame design with the 2500mW laser.

Thanks everyone for sharing their experiences so far. Here is one I did last night. The first "official" engraving for a customer. Also my first attempt at multi-line engraving. All alignments I did were by eye.

Keith, that came out great! Did you rotate the blank for the second line?

Regards,

Michael

Nice pointers in the videos, Keith - I like your use of the keyboard arrows and top-viewing to improve alignment.

- Bob