Joey-Nieves

Member

It says that it doesn't support windows 10

It says that it doesn't support windows 10

It says that it doesn't support windows 10

Michael - I should have gone for expedited shipping - I might be a little older when it arrives.

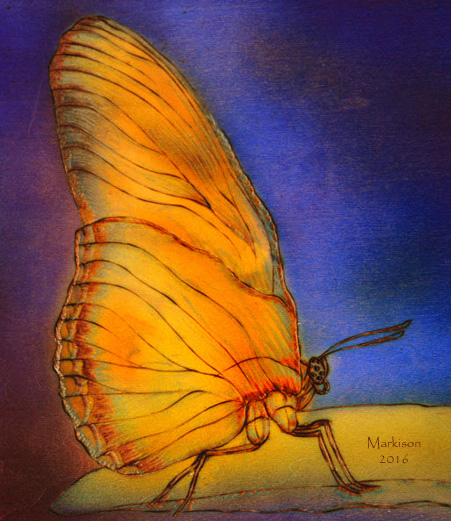

Here's what I meant about burning through water color - bass wood sanded to 1,000 grit; airbrushed/hand brushed watercolor, then pyrography with Razertip pen/hand ground points - about 3x4" (little commission for an entomologist):

I'm eager to combine laser and micro-pyrography burning - hence the impulse buy of the little laser unit.

Warm regards - Bob

Why are some of them missing sections or misaligning sections of the font? Going to be tough removing a bad engraving and doing it over!

Why are some of them missing sections or misaligning sections of the font? Going to be tough removing a bad engraving and doing it over!

That was due to how I had the blank placed on the work surface of the laser. It would bump into the framing supports of the laser and move the blank. I had to find the "sweet spot" on the surface to place the blank so the frame wouldn't have an affect on the engraving.

Another reason was because the laser would reach the end of the transom(?). It would stop moving but keep burning, then move on to the next line of pixels.

That makes sense, but what happened to the Corvette? The Ts are distorted, and the R is closed. Is that due to just holding it with rubber bands like lots of the videos?

Has anyone tried this laser engraver? I know it is a bit of an overkill for pen engraving but I like the higher power and larger work space if I ever needed it in the future. My only concern is that it is Windows 7 compatible but not Windows 10 and I am not sure if the backwards compatibility feature of Windows 10 will cover it. The seller said that it is NOT windows 10 compatible.

40W USB DIY Laser ENGRAVER Cutter Engraving Cutting Machine Laser Printer CO2 | eBay

I am working on adding a ebay bought blue diode laser which I believe is similar to the ones used in the NEJE machines. The holder it came with and focus lens limits it to around a 1" height from the work surface. At that height it cuts around .005-.007 thick line. I've been trying to post photos but for some reason I keep getting a reset message and can't post. The bad thing with the diode setup is the diodes are very sensitive and can degrade quickly. Currently I have a new one on order since it stopped engraving, I believe its my fault in how I handled the device.

As far as a CO2 laser, I was looking at that one also, all the commercial units use a CO2 design, just wont fit my application, I use a rotary axis.

Has anyone tried the 1000mW NEJE on stabilized wood?

Has anyone tried the 1000mW NEJE on stabilized wood?

Mine should be here around the first of next. Will try out some stabilized in it and report back.

Has anyone figured out what the 1.75mm White ABS Filament High Accuracy 3D Printer Accessories - 10M and the 3D Printer Brass Nozzle is for?

Has anyone figured out what the 1.75mm White ABS Filament High Accuracy 3D Printer Accessories - 10M and the 3D Printer Brass Nozzle is for?

isn't that the nozzle and filament for the 3D printers? the filament is what melts in layers to make the 3D forms, then nozzles just need to be replaced every now and then. sometimes due to changing colors or sizes in the filament. those aren't for the laser engraver.

Sometimes a cup of coffee and reading help but who reads directions.

Heres a shot showing the detail I was able to get from the laser diode setup.

Sometimes a cup of coffee and reading help but who reads directions.

Heres a shot showing the detail I was able to get from the laser diode setup.

can you load a larger picture to show the quality and details a bit better?

still on the fence about this thing, even though it is better than the alternative of spending $8K on a name brand laser.

Smik,

Are you using a 3D printer outfitted with a laser conversion?

No, I built a cnc router, aprox 3x4 footprint then added a rotary axis. I use a Bosch Colt router as a spindle and made a mount for the laser to fit into spindle collet. If I get back to the laser going to change the setup to a permanent mount.

Smik,

Are you using a 3D printer outfitted with a laser conversion?

I have just bought a 1000mW NEJE from Ebay, being shipped from Shen Zhen in China, cost just shy of £75 so worth a try, will keep you posted.

Here is the link: click here

What does that say? I wonder if you are ducting away the smoke? On traditional lasers, the lens can get fouled with smoke/resins and change the quality of the burn. No idea what these diodes have at the end and I doubt if the "instructions" will tell you about preventive maintenance.