You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Celtic knot take 2

- Thread starter duderubble

- Start date

Signed-In Members Don't See This Ad

See more from duderubble

The center of the knot must be in the same position for each cut. If you don't fill the cut with exact match to the kerf, you will be moving that center. I'll try attaching the picture again.

Sent from my iPad using Penturners.org mobile app

Haven't tried that but I'm pretty sure that wouldn't work, you would be lengthening the blank with each cut. These were cut partially through. These were cut with 1 and 2 opposite and 3 and 4 opposite. If you use this sequence, opposing sides will match. 2 will be over and 2 will be under. These were cut in my tablesaw and the kerf was matched. My saw kerf is .102. I like my infill to be .100.

Sent from my iPad using Penturners.org mobile app

Can you turn the pen 180 degrees and show the opposite side?? They should match the front side.

What I am getting at is the bands that make up the X in the center, the pen on the right the bands are over and the pen on the left they are under.

1 , blank must be perfectly square, ends must be square too, at least the end you are locating off, next to stop

2 , infill must match kerf

3 center hole must be drilled exactly on center

And if you number the blank in sequential order 1-2-3-4 and cut that way you end up with a knot that looks like Andy's avatar and the over under is different. I guess it is a matter of choice what looks better to you.

I will say this again clamp the ends and see what happens to the knot. Make that infill too tight and you starve the joint and push the sides out. I wish you luck if you can do it.

Yep. I think we got it!

But if you look at Ken's beauties there are no gaps.

Did you blow them up too??

OK Here's what I'm gonna do...

4. "Alternate" the blanks 1-3-2-4 then cut in numerical order to achieve the over-under

5. Keep doing the "don't cut all the way through" method then maybe try cutting all the way through but whatever I do the insert has to be EXACTLY the same width as the kerf to avoid misalignment and glue line gaps and so clamps aren't needed which distorts the blank when using the "don't cut" method.

6. use colored epoxy

7. I need to find a thin kerf blade with a flat top.

Signed-In Members Don't See This Ad

@KenB259

Could you give reasons, please, Ken. - reasons why "the infill must perfectly match the blade kerf ".

Also, your pictures are not accessible to me. . I am being told that I do not have permission to view. . Are they on a protected site ?

The center of the knot must be in the same position for each cut. If you don't fill the cut with exact match to the kerf, you will be moving that center. I'll try attaching the picture again.

Sent from my iPad using Penturners.org mobile app

jttheclockman

Member

Ken I too would like to know if you have tried using different thickness infill with the same size blade. I have not done that and would be interested.

This is getting to the point I may just drop all my projects and run some tests for all these scenarios.

Ken photos are showing here now. Did you cut all the way through the blank when you did these and if so did you match the thickness to the blade kerf and what saw did you use??

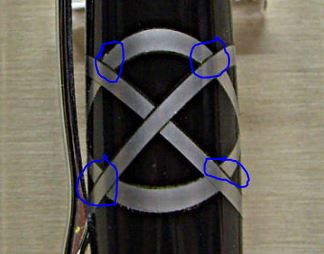

One more question, I see one pen has 4 loops over and one pen has 4 loops under. How did you accomplish that?? What was your sequence of cutting to make different??

This is getting to the point I may just drop all my projects and run some tests for all these scenarios.

Ken photos are showing here now. Did you cut all the way through the blank when you did these and if so did you match the thickness to the blade kerf and what saw did you use??

One more question, I see one pen has 4 loops over and one pen has 4 loops under. How did you accomplish that?? What was your sequence of cutting to make different??

Last edited:

Ken I too would like to know if you have tried using different thickness infill with the same size blade. I have not done that and would be interested.

This is getting to the point I may just drop all my projects and run some tests for all these scenarios.

Ken photos are showing here now. Did you cut all the way through the blank when you did these and if so did you match the thickness to the blade kerf and what saw did you use??

One more question, I see one pen has 4 loops over and one pen has 4 loops under. How did you accomplish that?? What was your sequence of cutting to make different??

Haven't tried that but I'm pretty sure that wouldn't work, you would be lengthening the blank with each cut. These were cut partially through. These were cut with 1 and 2 opposite and 3 and 4 opposite. If you use this sequence, opposing sides will match. 2 will be over and 2 will be under. These were cut in my tablesaw and the kerf was matched. My saw kerf is .102. I like my infill to be .100.

Sent from my iPad using Penturners.org mobile app

jttheclockman

Member

Can you explain that again?? I did not follow the over under.Haven't tried that but I'm pretty sure that wouldn't work, you would be lengthening the blank with each cut. These were cut partially through. These were cut with 1 and 2 opposite and 3 and 4 opposite. If you use this sequence, opposing sides will match. 2 will be over and 2 will be under. These were cut in my tablesaw and the kerf was matched. My saw kerf is .102. I like my infill to be .100.

Sent from my iPad using Penturners.org mobile app

Can you turn the pen 180 degrees and show the opposite side?? They should match the front side.

What I am getting at is the bands that make up the X in the center, the pen on the right the bands are over and the pen on the left they are under.

Last edited:

Thank you, @KenB259 . . Pic now helps. . Those 2 pens each have the symmetry I like ... didn't notice that last time you showed.

Your mention of keeping the center of the knot at the same position for each cut would require matching inset thickness to saw kerf.

Maintaining the knot center position could be the key concept . . Got some thinking to do now.

Your mention of keeping the center of the knot at the same position for each cut would require matching inset thickness to saw kerf.

Maintaining the knot center position could be the key concept . . Got some thinking to do now.

Last edited:

I think I cut the same as you do. I make my fist cut glue in the infill, rotate the blank 180 degrees for my second cut, glue in that infill. Make the third cut,glue in infill, rotate 180 degrees for the final cut. Look at your pen, rotate it 90 degrees, I bet one side is under and one side will be over.Can you explain that again?? I did not follow the over under.

That's exactly why infill must match kerf.Thank you, @KenB259 . . Pic now helps.

Your mention of keeping the center of the knot at the same position for each cut would require matching inset thickness to saw kerf.

jttheclockman

Member

No look at the last post in first page and I show both sides of my black and silver pen and both sides are over. I always do 1 and 2 opposite and 3 and 4 opposite and cut in order.I think I cut the same as you do. I make my fist cut glue in the infill, rotate the blank 180 degrees for my second cut, glue in that infill. Make the third cut,glue in infill, rotate 180 degrees for the final cut. Look at your pen, rotate it 90 degrees, I bet one side is under and one side will be over.

ramaroodle

Member

Excellent. So you go around the blank & number the first side 1 then the next side 3 then 2 then four then go back and cut 1-2-3-4 in that order?

Last edited:

jttheclockman

Member

That is how I do it.Excellent. So you number the sides 1,3,2,4 then cut 1 then 2 then 3 then 4??

jttheclockman

Member

I am wondering now if you number 1-4-2-3 as opposed to 1-3-2-4 turning the blank counterclockwise when numbering will give you weather the bands are over or under. My goodness that would be another test blank. I may start prepping some of this material tomorrow and then cut a few of these and just use CA glue to make this go faster. My curiosity is piqued.

But look at the side opposite the clip, so turn your pen so you can't see the clip and I bet it will be under.No look at the last post in first page and I show both sides of my black and silver pen and both sides are over. I always do 1 and 2 opposite and 3 and 4 opposite and cut in order.

I'm thinking it doesn't matter as long as 1 and 2 is opposing sides. As 3 and 4 will be.I am wondering now if you number 1-4-2-3 as opposed to 1-3-2-4 will give you weather the bands are over or under. My goodness that would be another test blank. I may start prepping some of this material tomorrow and then cut a few of these and just use CA glue to make this go faster. My curiosity is piqued.

That's how I do itExcellent. So you number the sides 1,3,2,4 then cut 1 then flip twice and cut # 2 then 3 then 4??

ramaroodle

Member

If you cut all the way through then there is no kerf per se right? As long as all of the infills are the same size it shouldn't matter should it?That's exactly why infill must match kerf.

ramaroodle

Member

Makes sense. JT, can't wait to see your test results.I'm thinking it doesn't matter as long as 1 and 2 is opposing sides. As 3 and 4 will be.

Yes it does matter, infill must still match the width of the saw blade. I think the best thing to do is glue one up with thicker infill than you blade and turn it. You'll see it won't turn out. I'd use scrap wood, because you'll be throwing it away.If you cut all the way through then there is no kerf per se right? As long as all of the infills are the same size it shouldn't matter should it?

Yes 2 opposing sides will be over and the other 2 will be over.@KenB259

Numbering the sides 1-3-2-4, or alternatively, 1-4-2-3 ..... are you saying these will give the same result for the "over-under" ?

ramaroodle

Member

Understood. It just doesn't register in my brain as the kerf then becomes the thickness of the infill rather than the blade but nobody ever said I was the sharpest blade in the shop. But....I think we're fast approaching the best technique!Yes it does matter, infill must still match the width of the saw blade. I think the best thing to do is glue one up with thicker infill than you blade and turn it. You'll see it won't turn out. I'd use scrap wood, because you'll be throwing it away.

By Joe! I think we've got it!Yes 2 opposing sides will be over and the other 2 will be over.

ramaroodle

Member

Wait. Now I get it! Yes! Makes sense as the amount of material you remove must be the same for each cut!!Yes it does matter, infill must still match the width of the saw blade. I think the best thing to do is glue one up with thicker infill than you blade and turn it. You'll see it won't turn out. I'd use scrap wood, because you'll be throwing it away.

jttheclockman

Member

OK I just went to shop to snap a couple photos and yes Ken is correct. If you rotate the blank 90 degrees then the 2 opposite knots will be under and the other are over. So you can choose whatever you like. But the thing we established is if you number the blank in opposite sequence 1opposite 2 and 3 opposite 4 then you wind up with all bands the same weather over or under

We are getting there. Good Celtic knots require these things.Understood. It just doesn't register in my brain as the kerf then becomes the thickness of the infill rather than the blade but nobody ever said I was the sharpest blade in the shop. But....I think we're fast approaching the best technique!

By Joe! I think we've got it!

1 , blank must be perfectly square, ends must be square too, at least the end you are locating off, next to stop

2 , infill must match kerf

3 center hole must be drilled exactly on center

jttheclockman

Member

So all we are left with is now the cutting all the way apart and using a different thickness infill and see what happens. If no on tries this then maybe I will give it a shot. The only time I cut all the way through was when I did the red and yellow sierras and I can not remember if I matched saw kerf material or not. I do not have those pens any more so would have to make new ones to test.

jttheclockman

Member

Yes we agree there and I have mentioned this a few times. Must drill center of knot and not the blank.We are getting there. Good Celtic knots require these things.

1 , blank must be perfectly square, ends must be square too, at least the end you are locating off, next to stop

2 , infill must match kerf

3 center hole must be drilled exactly on center

And if you number the blank in sequential order 1-2-3-4 and cut that way you end up with a knot that looks like Andy's avatar and the over under is different. I guess it is a matter of choice what looks better to you.

Interesting to actually see what this will look like, but I'd put my money on it that you'll get a lopsided knot.So all we are left with is now the cutting all the way apart and using a different thickness infill and see what happens. If no on tries this then maybe I will give it a shot. The only time I cut all the way through was when I did the red and yellow sierras and I can not remember if I matched saw kerf material or not. I do not have those pens any more so would have to make new ones to test.

ramaroodle

Member

The only thing I'd want to perfect is the small gaps but only an OCD pen geek would see that!

This really has been a fun exchange. Gotta go try this but I'm working thru Sunday

I think different thickness infills would screw it up.So all we are left with is now the cutting all the way apart and using a different thickness infill and see what happens. If no on tries this then maybe I will give it a shot. The only time I cut all the way through was when I did the red and yellow sierras and I can not remember if I matched saw kerf material or not. I do not have those pens any more so would have to make new ones to test.

This really has been a fun exchange. Gotta go try this but I'm working thru Sunday

I made a couple like that, I sold them both though. Funny, I thought they would sell as a pair, but they sold separately. I'm going to make two more sets of those for wedding gifts.So all we are left with is now the cutting all the way apart and using a different thickness infill and see what happens. If no on tries this then maybe I will give it a shot. The only time I cut all the way through was when I did the red and yellow sierras and I can not remember if I matched saw kerf material or not. I do not have those pens any more so would have to make new ones to test.

jttheclockman

Member

Can not be done and thus the coloring of the epoxy. They look worse in photo but if you saw with naked eye you would not see it.The only thing I'd want to perfect is the small gaps but only an OCD pen geek would see that!

View attachment 240240

I think different thickness infills would screw it up.

This really has been a fun exchange. Gotta go try this but I'm working thru Sunday

I will say this again clamp the ends and see what happens to the knot. Make that infill too tight and you starve the joint and push the sides out. I wish you luck if you can do it.

I'm a pen geek, and it looks fine to meThe only thing I'd want to perfect is the small gaps but only an OCD pen geek would see that!

View attachment 240240

I think different thickness infills would screw it up.

This really has been a fun exchange. Gotta go try this but I'm working thru Sunday

ramaroodle

Member

So you can choose whatever you like. But the thing we established is if you number the blank in opposite sequence 1opposite 2 and 3 opposite 4 then you wind up with all bands the same weather over or under

Yep. I think we got it!

ramaroodle

Member

Ah! The final element. The coloring of the epoxy, however, notice how the gaps are all on the same side of the line implying that it is a minor technique adjustment. Regardless, it's still stunning JT. What metal are you using, aluminum? And how thick?Can not be done and thus the coloring of the epoxy. They look worse in photo but if you saw with naked eye you would not see it.

But if you look at Ken's beauties there are no gaps.

Last edited:

jttheclockman

Member

wood my friend wood will compress someAh! The final element. The coloring of the epoxy! But if you look at Ken's beauties there are no gaps.

Did you blow them up too??

ramaroodle

Member

+100Things are starting to gel !!

Thanks to all participants in this discussion, .... and also to those that asked the questions at various points along the way.

We are writing a new chapter in the "Segmenting" book !!

ramaroodle

Member

You're right. As I said, they're stunning. Thanks for your patience and help.wood my friend wood will compress some

Did you blow them up too??

jttheclockman

Member

Did not see your question Andy. Yes it is aluminum and is 1/16" to match the kerf of my tablesaw blade which is 1/16" Now I sanded the metal to give some teeth and that is all. No clamping on this either. I do not believe in that. Just my thing. You do as you see fit.

We are answering all the knot questions for sure.

We are answering all the knot questions for sure.

ramaroodle

Member

Did not see your question Andy. Yes it is aluminum and is 1/16" to match the kerf of my tablesaw blade which is 1/16" Now I sanded the metal to give some teeth and that is all. No clamping on this either. I do not believe in that. Just my thing. You do as you see fit.

We are answering all the knot questions for sure.

OK Here's what I'm gonna do...

1 , blank must be perfectly square, ends must be square too, at least the end you are locating off, next to stop

2 , infill must match kerf

3 center hole must be drilled exactly on center

To me there's no question that mine is not the most esthetic as it's unbalanced.Yes we agree there and I have mentioned this a few times. Must drill center of knot and not the blank.

And if you number the blank in sequential order 1-2-3-4 and cut that way you end up with a knot that looks like Andy's avatar and the over under is different. I guess it is a matter of choice what looks better to you.

4. "Alternate" the blanks 1-3-2-4 then cut in numerical order to achieve the over-under

5. Keep doing the "don't cut all the way through" method then maybe try cutting all the way through but whatever I do the insert has to be EXACTLY the same width as the kerf to avoid misalignment and glue line gaps and so clamps aren't needed which distorts the blank when using the "don't cut" method.

6. use colored epoxy

7. I need to find a thin kerf blade with a flat top.

Last edited:

Signed-In Members Don't See This Ad

jttheclockman

Member

No need for flat top doing these. You turn away any cuts. Now if you can get your infill material close to exact size you can get away with clamping and have no gaps at all but need to be darn near dead on. If you are that good then clamp away. I just do not do it. As I said wood is different than metals and acrylic. Remember too we had this conversation before and recently here too that wood moves as well as metal and acrylic. Heck this black and silver blank I have been showing has the aluminum raised just a tad over the years that I made it. I may throw it back on the lathe and respin it and polish it again. It was baby's bottom smoothe when I first did it. But proof that even plastics move. So these segment pens we make especially with all the variety of woods used may not look and feel the same over time. Just a warning for those with OCD.