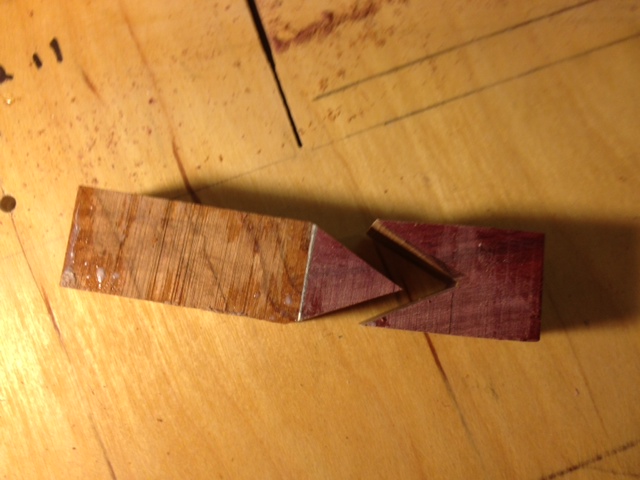

Yes the break is the thickness of the kerf of the blade, but the thickness of the aluminum has nothing to do with it. When you make the second cut you are cutting away part of the first scallop. Then gluing it back in minus the part you cut out because of the thickness of the blade. I know it is hard to see and visualize like I said in an earlier post it too firewhatfire to help me actually see it.

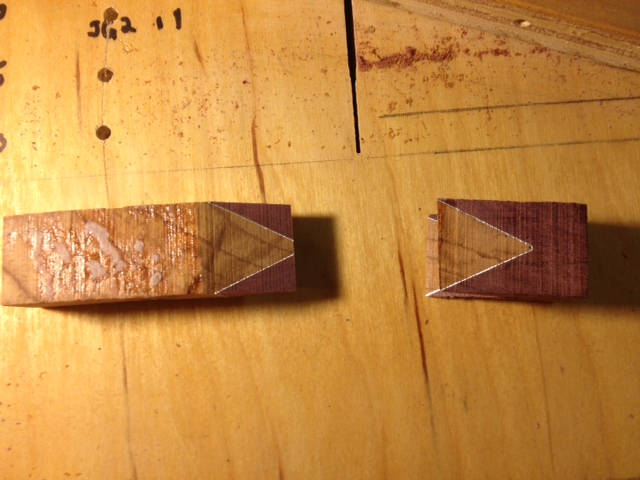

I think i can help explain whats going on here.....This picture explains it well. To the person who made this pen, Forgive me, I'm not sure who's pen this is, I just downloaded it a while back because I liked it and it helped me understand what was going on.

1st step is cut A. Then turn the blank and make cut B. when cut B is made, a slice comes out of the small piece left, labeled C. This essentially causes piece C to slide down the pen(or up in this picture) when this small slither was cut out because the rest of the pen did not move.