mikespenturningz

Member

Ok so after reading all over the place in this great forum and getting pointers from all those that did this long before me I decided to give this a try. Here are some of the steps it takes to make this work. It really isn't all that hard.

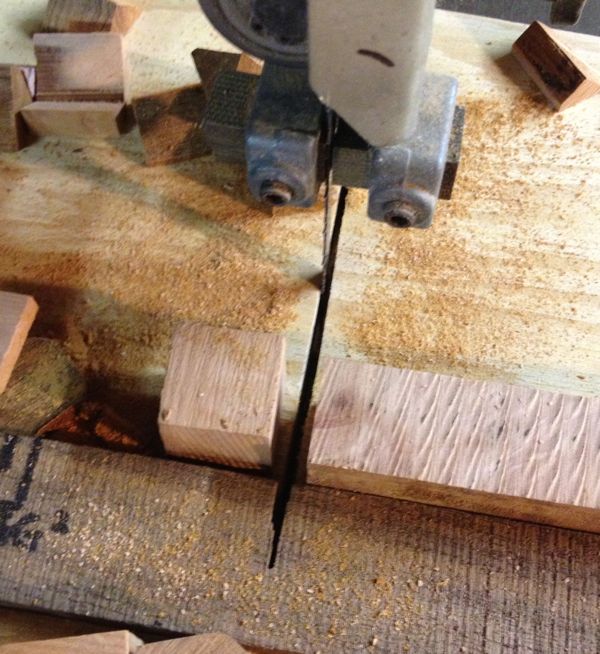

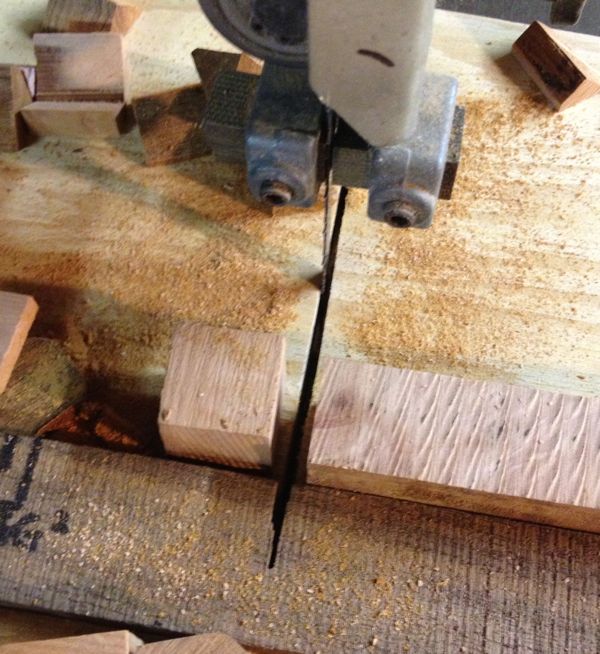

First take a blank and cut a cube out of it. This cut needs to be about square notice that I made a slide for my bandsaw and it really helps with all of these cuts.

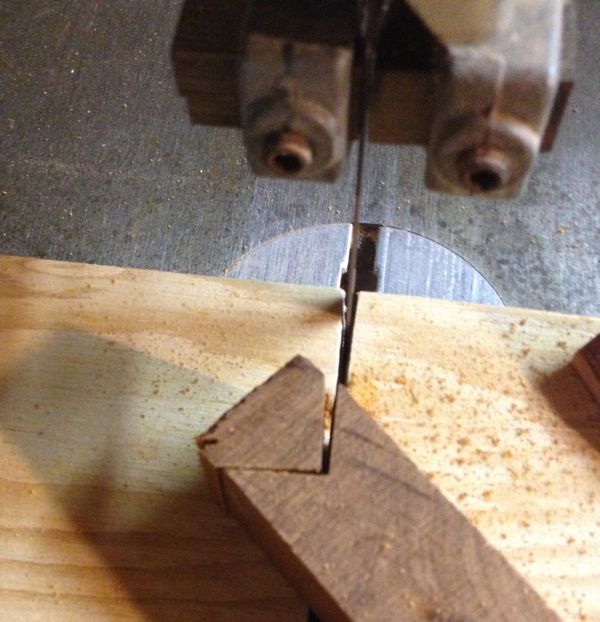

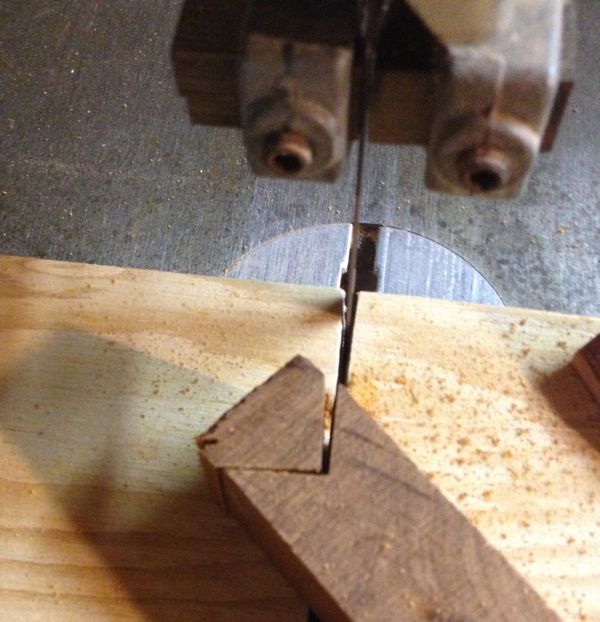

Then I use a V-Block to get a 45 degree angle still on my slide.

This is what your parts will look like when you are finished at the bandsaw. You will have to sand to make things nice and smooth.

Now take care of the aluminum. I used a dremel tool to cut the bottom and top off a Diet Coke can then used sheers to cut it into a sheet. Then I sanded the devil out of it. I used some 100 grit to make it nice and rough on both sides.

The next step is to fit the aluminum. I fold them then unfold them to about 90 degrees.

Now go ahead and start glueing them up. And clamp them overnight. I know it says 5 minute epoxy but it takes longer before it can take the kind of stresses of turning, drilling and more turning.

After proper drying time rough turn it down and then cut to length

I have learned that you have to drill these very slowly and I am still having some of them come apart. Be prepared to reglue if needed. I think also it may be better to drill them in steps? I will test this on the next one. When you are done you will have something special.

I hope this helps you.

First take a blank and cut a cube out of it. This cut needs to be about square notice that I made a slide for my bandsaw and it really helps with all of these cuts.

Then I use a V-Block to get a 45 degree angle still on my slide.

This is what your parts will look like when you are finished at the bandsaw. You will have to sand to make things nice and smooth.

Now take care of the aluminum. I used a dremel tool to cut the bottom and top off a Diet Coke can then used sheers to cut it into a sheet. Then I sanded the devil out of it. I used some 100 grit to make it nice and rough on both sides.

The next step is to fit the aluminum. I fold them then unfold them to about 90 degrees.

Now go ahead and start glueing them up. And clamp them overnight. I know it says 5 minute epoxy but it takes longer before it can take the kind of stresses of turning, drilling and more turning.

After proper drying time rough turn it down and then cut to length

I have learned that you have to drill these very slowly and I am still having some of them come apart. Be prepared to reglue if needed. I think also it may be better to drill them in steps? I will test this on the next one. When you are done you will have something special.

I hope this helps you.

Last edited: