Edward Cypher

Member

Plus 1 on Alisam Engineering!!! I have there indexer for a 10 inch lathe, works flawlessly!!!! Fast and friendly service.

Great post John. I had seen your pens a while back and tried to re-create the design. Not successfully! Qick question - where did you get the indexing plate that is attached to the lathe?

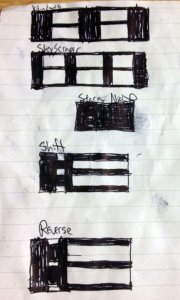

Here you go.

Alisam Engineering - Hand Tool Manufacturing: Jet mini-lathe indexing system

Very well made and fits very easily. Has enough indexing for what we need to do.

I plan on a few more pens hopefully over the Holiday I can find some shop time. I have a week off.