You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ebony and Holly

- Thread starter KenB259

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

jttheclockman

Member

I am a sucker for that combination. Nothing better. Correct no sandpaper anywhere near those. All turning tools. Suggestion is to try whatever finish you are going to use on scraps if you have. The first seal coat ic the most important. Good luck and look forward to seeing them done.

hokie

Member

What's your plan to keep the holly free of ebony dust while achieving a smooth surface without tool marks?

sorcerertd

Member

I agree and might do the same thing if I were you! Still, I can't help but anticipate the finished product.They are so pretty as is, I'm going to admire them awhile before turning.

I wonder if the holly had been stabilized first, if it might have helped keep black dust out of the holly? Even with just tooling, you'll still create dust. I have some holly here, that I've had for a while. Its very light weight and soft, and I've not turned much of it yet, as it picks up EVERYTHING...even dust from other turnings, if you haven't cleaned it up sufficiently, can end up in holly. I have long wondered if I stabilized it first, then turned, if that might help...

SteveJ

Member

Beautiful blanks!

jttheclockman

Member

Final cuts with a good sharp skew will bring it home with no tool marks and no sanding dust or contamination. I have used that combo a few times and no problems.

Well, in reality, I sand very few of my pens.What's your plan to keep the holly free of ebony dust while achieving a smooth surface without tool marks?

I use a lot of holly, never have to much of an issue with it, other than it's scarcity of quality stock and it's price.I wonder if the holly had been stabilized first, if it might have helped keep black dust out of the holly? Even with just tooling, you'll still create dust. I have some holly here, that I've had for a while. Its very light weight and soft, and I've not turned much of it yet, as it picks up EVERYTHING...even dust from other turnings, if you haven't cleaned it up sufficiently, can end up in holly. I have long wondered if I stabilized it first, then turned, if that might help...

JohnU

Member

They look great! If you applied some ultra thin ca (Gluboost red label) before sanding, if would wick in enough to stop any dark sanding dust from discoloring the holy, as long as its was light sanding for finishing.

It's on my Christmas list, but can I wait that long!!They look great! If you applied some ultra thin ca (Gluboost red label) before sanding, if would wick in enough to stop any dark sanding dust from discoloring the holy, as long as its was light sanding for finishing.

leehljp

Member Liaison

John, as Ken and John T mentioned, with the proper tools - sanding isn't needed. Proper tool sharpening and use - and the wood is every bit as smooth (and smoother) as the finest sandpaper. AND sandpaper smears wood dust like this.They look great! If you applied some ultra thin ca (Gluboost red label) before sanding, if would wick in enough to stop any dark sanding dust from discoloring the holy, as long as its was light sanding for finishing.

I initially learned to use the tool to prevent the sanding dust, then learned that the proper use of sharp tools were smoother than sanding of any kind.

For anyone concerned about tool marks, then the tool is not sharp enough.

JohnU

Member

Lee I completely understand that but my comment is for those who aren't at that level of turning. Many people still like to use sand paper for this subtle tapers and smoothing out the surface.

jttheclockman

Member

John, so many times you get the same old question here about contaminating different woods when sanding. So the answer is do not sand. Now you mention CA as a blocking solution, my answer to that is maybe. If you do that you need to do a trial thing because liquids will carry colors from one to other. Especially such as ebony which is a dark heavy and tight grain and holly which is a white soft grain wood. This is why I mentioned in my response to do some trial first. I have seen this happen even with shellac as the sealer. Plus when you wipe from one to other can contaminate. The best practice is to get to finish sized with tools and avoid sandpaper and then be careful with the finish. A light coat of spray on sanding sealer will work. Then finish with CA. Just my thoughts about sanding delicate woods.Lee I completely understand that but my comment is for those who aren't at that level of turning. Many people still like to use sand paper for this subtle tapers and smoothing out the surface.

jttheclockman

Member

At one time I had an excellent source for clean pure white holly but when I changed computers I lost some contacts and that was one and have no idea what that name was any more. I still have some stock left. but one thing with holly it is crucial when it is harvested. Likes to be cut in winter months to stay white or else you get grey streaks in it. I have recently bought a bunch of aspen and my next pen I want to mix white and black I am going to try Aspen because it is a very close second to the white of holly.

Cook woods has a piece right now that looks pristine, but it also has a price tag of 247 dollars. My local wood store has it from time to time, in fact they have a couple of pieces right now, but they are pretty low quality and full of cracks and knots.At one time I had an excellent source for clean pure white holly but when I changed computers I lost some contacts and that was one and have no idea what that name was any more. I still have some stock left. but one thing with holly it is crucial when it is harvested. Likes to be cut in winter months to stay white or else you get grey streaks in it. I have recently bought a bunch of aspen and my next pen I want to mix white and black I am going to try Aspen because it is a very close second to the white of holly.

mark james

IAP Collection, Curator

Superb blanks 'in the rough.' I look forward to the turned result. From my eye - Awesome. But 1/4" away from the 'inner' result is the key. I hate waiting

.

.

There's also the fact, because of the design, they have to be drilled straight.Superb blanks 'in the rough.' I look forward to the turned result. From my eye - Awesome. But 1/4" away from the 'inner' result is the key. I hate waiting

.

sorcerertd

Member

with all this talk about stabilizing, ultra thin CA (I use the GluBoost ultra quite often), to sand or not to sand... somebody should glue up some scraps, test, then show us the results.

I am not perfect with a skew and my skews are not scary sharp, but I still don't sand most of my finished blanks. I don't know about everyone else, but I've definitely made things worse on a few occasions trying to fix a little flaw that most people probably wouldn't have noticed. No matter the end result with the skew, I would be scared to sand these.

I am not perfect with a skew and my skews are not scary sharp, but I still don't sand most of my finished blanks. I don't know about everyone else, but I've definitely made things worse on a few occasions trying to fix a little flaw that most people probably wouldn't have noticed. No matter the end result with the skew, I would be scared to sand these.

You can do a lot of experimenting as soon as you turn a blank round. You're not even close to finish size and it'll all just get turned away.with all this talk about stabilizing, ultra thin CA (I use the GluBoost ultra quite often), to sand or not to sand... somebody should glue up some scraps, test, then show us the results.

I am not perfect with a skew and my skews are not scary sharp, but I still don't sand most of my finished blanks. I don't know about everyone else, but I've definitely made things worse on a few occasions trying to fix a little flaw that most people probably wouldn't have noticed. No matter the end result with the skew, I would be scared to sand these.

sorcerertd

Member

That's very true and completely eluded me. Lord knows I have done it on many occasions, especially learning to get my CA finish right.You can do a lot of experimenting as soon as you turn a blank round. You're not even close to finish size and it'll all just get turned away.

This is the part that scares me with my track record. I'll get there one of these days.There's also the fact, because of the design, they have to be drilled straight.

leehljp

Member Liaison

Oh, I'm apologize. I misunderstood it when the reply to Ken was "If you applied some ultra thin ca (Gluboost red label) before sanding". I read that as though you were talking to him.Lee I completely understand that but my comment is for those who aren't at that level of turning. Many people still like to use sand paper for this subtle tapers and smoothing out the surface.

Last edited:

leehljp

Member Liaison

John, so many times you get the same old question here about contaminating different woods when sanding. So the answer is do not sand. Now you mention CA as a blocking solution, my answer to that is maybe. If you do that you need to do a trial thing because liquids will carry colors from one to other. Especially such as ebony which is a dark heavy and tight grain and holly which is a white soft grain wood. This is why I mentioned in my response to do some trial first. I have seen this happen even with shellac as the sealer. Plus when you wipe from one to other can contaminate. The best practice is to get to finish sized with tools and avoid sandpaper and then be careful with the finish. A light coat of spray on sanding sealer will work. Then finish with CA. Just my thoughts about sanding delicate woods.

Back in 2007-8 when I became very allergic to CA fumes and dust, I tried several finishing methods, including the solution that includes acetone and melting acrylic. Very quickly, I discovered that acetone and some other different based liquids would transfer ebony and also bloodwood colors (at least what was bloodwood back then). They made messes on holly (and maple/magnolia/Aspen etc) and also distorted the hue/tent on original colors on the ebony and bloodwood.

leehljp

Member Liaison

with all this talk about stabilizing, ultra thin CA (I use the GluBoost ultra quite often), to sand or not to sand... somebody should glue up some scraps, test, then show us the results.

I am not perfect with a skew and my skews are not scary sharp, but I still don't sand most of my finished blanks. I don't know about everyone else, but I've definitely made things worse on a few occasions trying to fix a little flaw that most people probably wouldn't have noticed. No matter the end result with the skew, I would be scared to sand these.

I agree with you! IF I mess up and sand through the CA to the perfectly smooth blank (from turning smooth with the tool), Yes I mess up! A good thick coat of CA or other puts on an even coat and it cures fairly evenly. BUT sand through in a spot, or turn through in a spot, and minute' (minuscule) color differences show up that LOML doesn't see, but I sure do! It just makes it worse and the best thing I can do is turn ALL the finish off and start over with applying finish.

jttheclockman

Member

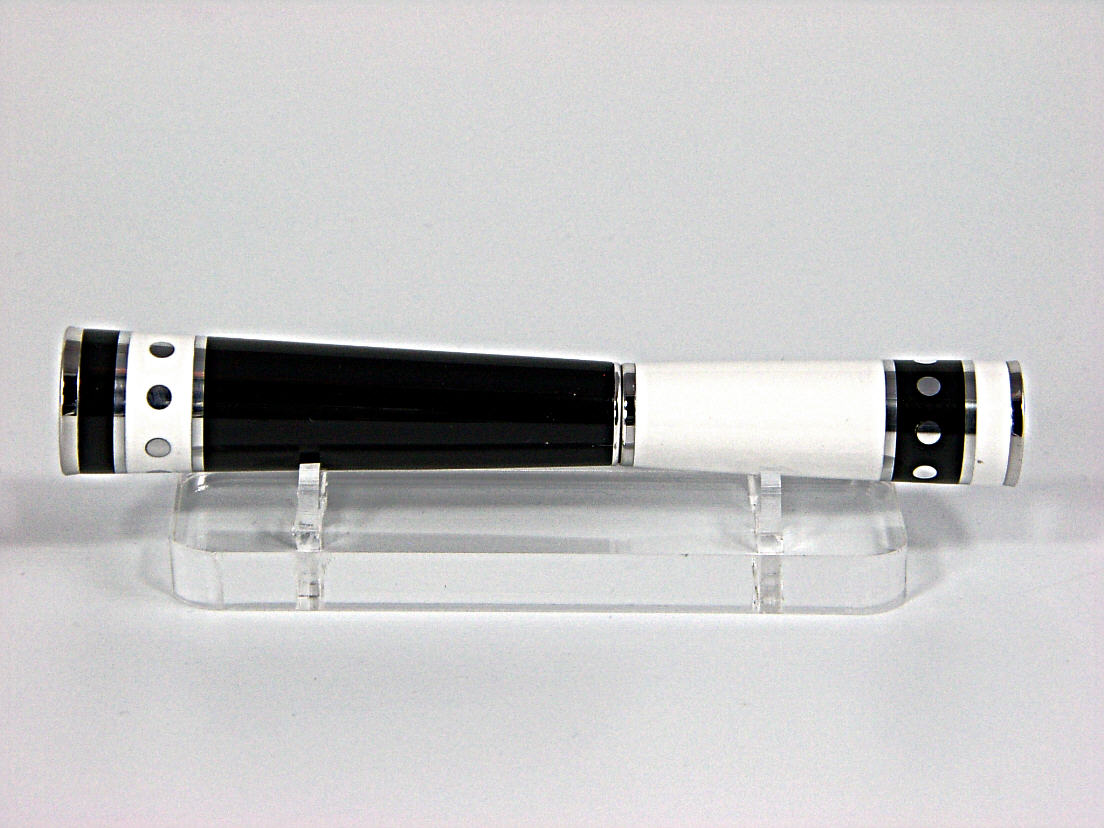

That is the other problem when you talk museum grade or pristine the price sure goes up. As I said I am good for now. I have been doing my black and white blanks with acrylic these days. I know I have shown these many times here and people are tired of seeing them but they are examples of turning with tools (skew for final turning as always) only and no sandpaper. I hit the rounded blank with the quickest spray of clear dewaxed shellac with lathe turning slow. After it dried and was sealed it was CA as a finish as normal and no bleeding. Works for me.Cook woods has a piece right now that looks pristine, but it also has a price tag of 247 dollars. My local wood store has it from time to time, in fact they have a couple of pieces right now, but they are pretty low quality and full of cracks and knots.

leehljp

Member Liaison

John, I don't think you are showing the examples too much. These are good examples of what can be done repeatedly. You use a skew and I use an HSS scraper to achieve the same smoothness so that no SP is needed. I will admit that the knife edge of a skew can do more overall than a scraper. While I am able to pull this off with an HSS scraper, I am not sure a carbide insert can do as well because I don't know just how sharp even the best carbide inserts are.That is the other problem when you talk museum grade or pristine the price sure goes up. As I said I am good for now. I have been doing my black and white blanks with acrylic these days. I know I have shown these many times here and people are tired of seeing them but they are examples of turning with tools (skew for final turning as always) only and no sandpaper. I hit the rounded blank with the quickest spray of clear dewaxed shellac with lathe turning slow. After it dried and was sealed it was CA as a finish as normal and no bleeding. Works for me.

I was going over this in my mind yesterday. There is good, then there is better and then best. After learning the smoothness that can be achieved from the tool itself (and without tool scratches as some think) I started using SP less and less. I still use SP on occasion and in specific situations, - such as an occasional very delicate segment in which I might sand to close to size with 400 SP, after which I change to the tool to finish. The vast majority of times, smoothness comes from the tool on a level that SP is difficult to achieve, and especially when using segments and the prevention of sanding dust. Erasers, DNA don't even come close to cleaning the sanding dust from segments like a good sharp tool.

People who do not understand this are also not familiar with some of the finest woodworking techniques - that use hand scrapers to achieve a smoothness that SP (sandpaper) cannot achieve. For a pen turner to "level up" (a Japanese term that I learned long ago) in both skill and the quality of product, repeated postings bring this to the forefront for many that miss it. I am seeing more turners here comment on the idea of using a sharp tool instead of SP. I am not the most skilled person and have Parkinsons. My hands shake in many situations, but resting the tool on the tool rest still allows me to make smooth wood that 800SP dreams about.

Thank you John. Keep posting when relevant. It helps other to "Level UP".

sorcerertd

Member

Nope, not me. Keep showing them.I know I have shown these many times here and people are tired of seeing them

ZanderPommo

Member

This is incredibleThat is the other problem when you talk museum grade or pristine the price sure goes up. As I said I am good for now. I have been doing my black and white blanks with acrylic these days. I know I have shown these many times here and people are tired of seeing them but they are examples of turning with tools (skew for final turning as always) only and no sandpaper. I hit the rounded blank with the quickest spray of clear dewaxed shellac with lathe turning slow. After it dried and was sealed it was CA as a finish as normal and no bleeding. Works for me.

View attachment 361943View attachment 361944

People who do not understand this are also not familiar with some of the finest woodworking techniques - that use hand scrapers to achieve a smoothness that SP (sandpaper) cannot achieve. For a pen turner to "level up" (a Japanese term that I learned long ago) in both skill and the quality of product, repeated postings bring this to the forefront for many that miss it. I am seeing more turners here comment on the idea of using a sharp tool instead of SP. I am not the most skilled person and have Parkinsons. My hands shake in many situations, but resting the tool on the tool rest still allows me to make smooth wood that 800SP dreams about.

The topic of the thread aside (I understand the benefits of a skew to avoid embedding sanding dust in light woods), I just have to dispute that you cannot achieve as smooth a surface with sanding.

You mention 800 grit...which, in my experience, is not all that high when its pens we are talking about. I've sanded up to 5000 grit, and frequently sand up to 3000 grit. With good technique, and the final pass manually sanding with the grain to ensure no radial sanding bands are evident, you can achieve an EXCEPTIONALLY smooth result with sandpaper. You just need to go beyond 800 grit to do it.

I've been working with skews lately. I'm getting better, and have had a few occasions where I've achieved extremely smooth results (still working on technique, so I don't rely on this for any pen work just yet due to my fear of the occasional catch). The skew can indeed produce extremely smooth results. That's not in dispute. In the end, though, I honestly can't say that the results were smoother than 3000 grit, or even 2000 grit. I am not sure that the skew can quite achieve the level of smoothness that can be achieved with say 1 micron Zona Paper, either...that stuff is a whole nother beast and a whole nother level... Zona is my final finishing sandpaper, and it never fails to impress.

Now, if you are trying to avoid coloring say holly or even maple, with darker or brightly colored sanding dust, then sanding is not necessarily going to do the job. A skew is undoubtedly the better tool. I'm just saying, skew level smoothness is not impossible with sandpaper. I get naturally shiny results with sandpaper all the time, sometimes even a fairly tight shine line, just with sandpaper, so long as I go to the higher grits where we are talking scratches in the 1 micron range. For hard, oily woods, wet sanding can be used (with oil is usually the case for me), and a fine shine line can be achieved with sanding. I suspect if one were to properly stabilize holly, then it wouldn't pick up sanding dust in the end, for those who don't have the skew skill (of all the tools I've used, the skew is the only one that ever seems to catch, and all it takes is being off the bevel the slightest amount, or at the wrong angle to the wood, and it can happen.)

leehljp

Member Liaison

1. In context of this thread, and keep in mind the CONTEXT OF SEGMENTS: sanding of ANY kind will SMEAR SANDING DUST. So, sanding in total has to be eliminated.The topic of the thread aside (I understand the benefits of a skew to avoid embedding sanding dust in light woods), I just have to dispute that you cannot achieve as smooth a surface with sanding.

You mention 800 grit...which, in my experience, is not all that high when its pens we are talking about. I've sanded up to 5000 grit, and frequently sand up to 3000 grit. With good technique, and the final pass manually sanding with the grain to ensure no radial sanding bands are evident, you can achieve an EXCEPTIONALLY smooth result with sandpaper. You just need to go beyond 800 grit to do it.

I've been working with skews lately. I'm getting better, and have had a few occasions where I've achieved extremely smooth results (still working on technique, so I don't rely on this for any pen work just yet due to my fear of the occasional catch). The skew can indeed produce extremely smooth results. That's not in dispute. In the end, though, I honestly can't say that the results were smoother than 3000 grit, or even 2000 grit. I am not sure that the skew can quite achieve the level of smoothness that can be achieved with say 1 micron Zona Paper, either...that stuff is a whole nother beast and a whole nother level... Zona is my final finishing sandpaper, and it never fails to impress.

Now, if you are trying to avoid coloring say holly or even maple, with darker or brightly colored sanding dust, then sanding is not necessarily going to do the job. A skew is undoubtedly the better tool. I'm just saying, skew level smoothness is not impossible with sandpaper. I get naturally shiny results with sandpaper all the time, sometimes even a fairly tight shine line, just with sandpaper, so long as I go to the higher grits where we are talking scratches in the 1 micron range. For hard, oily woods, wet sanding can be used (with oil is usually the case for me), and a fine shine line can be achieved with sanding. I suspect if one were to properly stabilize holly, then it wouldn't pick up sanding dust in the end, for those who don't have the skew skill (of all the tools I've used, the skew is the only one that ever seems to catch, and all it takes is being off the bevel the slightest amount, or at the wrong angle to the wood, and it can happen.)

2. I know your penchant for absolute scientific data results. I really don't give a hoot for that when I can get something to work and work exceedingly well and be repeatable. Getting absolute data will just have to be your problem, as that is not my purpose. I and some others know that tools will and can produce super results regardless of what you believe . Here is a link for you:

"Scraping produces a cleaner surface than sanding;" it (the cutting edge) does not "scrape" but shears the fibers at the surface level instead of spreading fine sanding dust that fills in pores. While that is with flat work, the same principle applies with properly sharpened chisel tools. (This is why I use HSS that I can sharpen. I haven't found carbide inserts that can match my sharpened HSS. It may be out there but I am not going to hunt them down because I don't need them. I am not a super sharpener, I am just persistent, consistent and patient in sharpening. My tools "shear" the fibers at the surface level. Scrapers properly sharpened will do this. Skews will do this, Period!

3. 800 - I was wrong to use that considering it is you that would read it. How about 3000, or 5000? OK, so which sanding grit chart are you using? The numbers have different meanings in different charts. BUT the number is irrelevant with segments because they spread sanding dust and contaminate the different colors. PERIOD!

4. IF you want to get back to scraping vs sanding, the same principle applies, shearing the fibers produces smoother cuts than sanding. Period!

5. Radial sanding bands: If you think all tools or scrapers leave sanding bands or scraping bands, then that is your problem. Of course if you look with an electron microscope you MAY find them. but compare the 5000 /10000 to precisely sharpened shear cuts and there will be no dust or radial lines.

I have a 5x and a 10X loupe. I haven't seen a radial line in 14 - 15 years. And coming back to the original, no sanding dust with shear cuts and no contamination

No sanding done on the wood or segments: this was 14 years ago

30 Pieces of Silver

Elegant Beauty TI Gold Bloodwood, BOW, Holly core solder CA finish

www.penturners.org

Close up shot but before final shearing/scraping and applying finish. No radial lines. No sanding done.

:https://www.penturners.org/media/clip-end-close-up.21863/

Last edited:

I agree. It doesn't matter how fine the sandpaper is, your just smearing smaller specks of material, probably worse than coarser grits.1. In context of this thread, and keep in mind the CONTEXT OF SEGMENTS: sanding of ANY kind will SMEAR SANDING DUST. So, sanding in total has to be eliminated.

2. I know your penchant for absolute scientific data results. I really don't give a hoot for that when I can get something to work and work exceedingly well and be repeatable. Getting absolute data will have to be your cross to bear. I and others know that tools will and can produce super results. Here is a link for you:

"Scraping produces a cleaner surface than sanding;" it (the cutting edge) does not "scrape" but shears the fibers at the surface level instead of spreading fine sanding dust that fills in pores. While that is with flat work, the same principle applies with properly sharpened chisel tools. (This is why I use HSS that I can sharpen. I haven't found carbide inserts that can match my sharpened HSS. It may be out there but I am not going to hunt them down because I don't need them. I am not a super sharpener, I am just persistent, consistent and patient in sharpening. My tools "shear" the fibers at the surface level. Scrapers properly sharpened will do this. Skews will do this, Period!

3. 800 - I was wrong to use that considering it is you that would read it. How about 3000, or 5000? OK, so which sanding grit chart are you using? The numbers have different meanings in different charts. BUT the number is irrelevant with segments because they spread sanding dust and contaminate the different colors. PERIOD!

4. IF you want to get back to scraping vs sanding, the same principle applies, shearing the fibers produces smoother cuts than sanding. Period!

5. Radial sanding bands: If you think all tools or scrapers leave sanding bands or scraping bands, then that is your problem. Of course if you look with an electron microscope you MAY find them. but compare the 5000 /10000 to precisely sharpened shear cuts and there will be no dust or radial lines.

I have a 5x and a 10X loupe. I haven't seen a radial line in 14 - 15 years. And coming back to the original, no sanding dust with shear cuts and no contamination

jttheclockman

Member

Jon, I get what you are saying about sanding, but what both Ken and Hank are talking about and even myself, when it comes to sanding segmented pieces you always run the risk of cross contamination of sanding dust getting in the pores of the lighter woods. It is just natural for this to happen no matter which way you sand and what grit sandpaper you use. When you use a tool such as a skew you are actually cutting the fibers instead of sanding them and laying them down. Same goes with scraper such as what Hank talks about that are used on large wooden products. A good carpenter can use handheld scraper to surface a board that will feel like a baby's bottom. Now even those, sharpness counts when honing those type tools.

But to take this even further because you talk about grits that are super fine when you start getting into 800 grit and beyond. There is no reason that you need to go past 400 at most. Yes I have done 600 grit but depends on species of wood. The finish you apply to the wood will fill all those tiny grains and the build up will level them out and then you sand and polish the finish coat to those type grit number. You go beyond 6oo grit on wood you will never feel it or see the difference under the finish. As far as using a loop and all that, that is not for me. The naked eye can not see those type swirls or minute scratches. But you are correct you can achieve a great smooth feel to wood if you sand alone. Those that make those cutting boards and use all the type of colored woods also run the risk of cross contamination in lighter colored woods. here is where handheld card scrapers come in handy to avoid this and until you seal the wood. I know I just like my skew and has worked for me.

But to take this even further because you talk about grits that are super fine when you start getting into 800 grit and beyond. There is no reason that you need to go past 400 at most. Yes I have done 600 grit but depends on species of wood. The finish you apply to the wood will fill all those tiny grains and the build up will level them out and then you sand and polish the finish coat to those type grit number. You go beyond 6oo grit on wood you will never feel it or see the difference under the finish. As far as using a loop and all that, that is not for me. The naked eye can not see those type swirls or minute scratches. But you are correct you can achieve a great smooth feel to wood if you sand alone. Those that make those cutting boards and use all the type of colored woods also run the risk of cross contamination in lighter colored woods. here is where handheld card scrapers come in handy to avoid this and until you seal the wood. I know I just like my skew and has worked for me.

Again...for segmented blanks, I'm not disputing you. My post very explicitly (and I stated as much) disputed only the notion that sanding could NEVER achieve as smooth a result as a tool. This is something you state often, and I'm sorry, but its false. This is REGARDLESS of the context of turning segmented blanks.1. In context of this thread, and keep in mind the CONTEXT OF SEGMENTS: sanding of ANY kind will SMEAR SANDING DUST. So, sanding in total has to be eliminated.

2. I know your penchant for absolute scientific data results. I really don't give a hoot for that when I can get something to work and work exceedingly well and be repeatable. Getting absolute data will just have to be your problem, as that is not my purpose. I and some others know that tools will and can produce super results regardless of what you believe . Here is a link for you:

"Scraping produces a cleaner surface than sanding;" it (the cutting edge) does not "scrape" but shears the fibers at the surface level instead of spreading fine sanding dust that fills in pores. While that is with flat work, the same principle applies with properly sharpened chisel tools. (This is why I use HSS that I can sharpen. I haven't found carbide inserts that can match my sharpened HSS. It may be out there but I am not going to hunt them down because I don't need them. I am not a super sharpener, I am just persistent, consistent and patient in sharpening. My tools "shear" the fibers at the surface level. Scrapers properly sharpened will do this. Skews will do this, Period!

3. 800 - I was wrong to use that considering it is you that would read it. How about 3000, or 5000? OK, so which sanding grit chart are you using? The numbers have different meanings in different charts. BUT the number is irrelevant with segments because they spread sanding dust and contaminate the different colors. PERIOD!

4. IF you want to get back to scraping vs sanding, the same principle applies, shearing the fibers produces smoother cuts than sanding. Period!

5. Radial sanding bands: If you think all tools or scrapers leave sanding bands or scraping bands, then that is your problem. Of course if you look with an electron microscope you MAY find them. but compare the 5000 /10000 to precisely sharpened shear cuts and there will be no dust or radial lines.

I have a 5x and a 10X loupe. I haven't seen a radial line in 14 - 15 years. And coming back to the original, no sanding dust with shear cuts and no contamination

No sanding done on the wood or segments: this was 14 years ago

30 Pieces of Silver

Elegant Beauty TI Gold Bloodwood, BOW, Holly core solder CA finishwww.penturners.org

Close up shot but before final shearing/scraping and applying finish. No radial lines. No sanding done.

:https://www.penturners.org/media/clip-end-close-up.21863/

As I already mentioned in my previous post (which you clearly didn't read entirely), I agree that a tool is undoubtedly the better solution to the problem posed in this thread.

As mentioned in my previous post (does anyone actually read??), I'm not disputing the benefits of a skew for turning segmented blanks.Jon, I get what you are saying about sanding, but what both Ken and Hank are talking about and even myself, when it comes to sanding segmented pieces you always run the risk of cross contamination of sanding dust getting in the pores of the lighter woods. It is just natural for this to happen no matter which way you sand and what grit sandpaper you use. When you use a tool such as a skew you are actually cutting the fibers instead of sanding them and laying them down. Same goes with scraper such as what Hank talks about that are used on large wooden products. A good carpenter can use handheld scraper to surface a board that will feel like a baby's bottom. Now even those, sharpness counts when honing those type tools.

But to take this even further because you talk about grits that are super fine when you start getting into 800 grit and beyond. There is no reason that you need to go past 400 at most. Yes I have done 600 grit but depends on species of wood. The finish you apply to the wood will fill all those tiny grains and the build up will level them out and then you sand and polish the finish coat to those type grit number. You go beyond 6oo grit on wood you will never feel it or see the difference under the finish. As far as using a loop and all that, that is not for me. The naked eye can not see those type swirls or minute scratches. But you are correct you can achieve a great smooth feel to wood if you sand alone. Those that make those cutting boards and use all the type of colored woods also run the risk of cross contamination in lighter colored woods. here is where handheld card scrapers come in handy to avoid this and until you seal the wood. I know I just like my skew and has worked for me.

I also disagree about going past 400 grit. It depends on a few things. I also use Pens Plus as a finish. There is most definitely a difference in the final results, between 400, 600, 800 grit, and 3000 grit. A very obvious difference. Its not about feel, its about results. I spent two years figuring out how to get glass like optimal results with Pens Plus, hence the very reason why I sand to 3000 grit.

Even with my CA finishing that I'm doing now, I can see 800 grit scratches through the CA. Now, I'm not all that old yet, I'm in my 40s, but I can definitely see 800 grit scratches, in the wood, through a GluBoost finish. So I've been sanding to 1200 or 1500, as necessary, until I can no longer see these scratches. I am nearsighted, so that might be part of it, but there are factors...such as shading. I find that 800 grit scratches can show up better on certain woods with certain angles of light.

Again, my previous post was responding to something very specific, and I clearly stated the topic of the thread aside.

IN the context of the thread, I again...don't disagree with you guys about the benefits of a skew to avoid getting sanding dust in the grain with segmented blanks. That said, not everyone can use a skew, and I still pose the question:

If you stabilize the wood (i.e. Cactus Juice) before hand, would it still be an issue?

I ask, because I've actually turned segmented blanks that were made out of stabilized wood. In fact, they were made out of stabilized woods, resins and honeycomb metal mesh, all together. Several of these blanks had soft maple, some resins, and bright or dark woods like paduke, yellowheart, walnut, ebony. I couldn't use a skew at all back then, and sanded without any issues with dust in the grains. I always suspected it was because the grain was full of stabilizing resin. So maybe that's an option for people who aren't Japanese-trained in the dark arts of skewtasticness....

Anyway. Please read ALL of my posts...you guys clearly missed my disclaimers.

rixstix

Member

Anyway. Please read ALL of my posts...you guys clearly missed my disclaimers.

TLDR.

I comprehend bulleted text better than novels.

jttheclockman

Member

First thing, I have no idea about stabilizing woods. Never done it never used them. I have used wood hardener for stain purposes and for fixing rot. I will leave that to you. Sanding to 3000 if you can see those difference you have Xray vision my friend. You can feel differences yes but my point is when you put a solid finish coat such as lacquer, poly or CA on wood you will never feel that wood again. Pen Plus is a friction polish and wears off so you will feel the wood and it is thin. But that maybe the look you are after. If you a seeing scratches past 600 grit you are sanding wrong. Just going lengthwise hides those radial scratches by nature. This is why when doing flat work they always say sand with the grain. Now people may not be able to use a skew but they may not also be able to stabilize woods. I think it is easier to learn with a tool that you have anyway. It really is not rocket science. There are so many videos out there to show the proper methods and practice gets you to Carnegie Hall. Do whatever you want but whenever this topic comes up I will always recommend not to sand segmented wood blanks. I sand straight grained woods and do not use a skew at times too. But 600 grit is as high as I go. I top coat with a solid finish. Good luck

One other point that does not get mentioned but I defy you to try sanding a segmented blank with hard materials such as metal or even plastic when used as separators and sand it flush. Good luck with that. Wood sands faster than hard materials. Even if you sand with a wood backer on sandpaper. very tough to do. I can not do it when I make my segmented blanks with acrylic and aluminum materials combined. I would never been able to sand this blank down evenly and there is no cross contamination involved in it. You would feel all the transition points between materials. Acrylic sand faster than aluminum. Had to use a skew. Just saying.

One other point that does not get mentioned but I defy you to try sanding a segmented blank with hard materials such as metal or even plastic when used as separators and sand it flush. Good luck with that. Wood sands faster than hard materials. Even if you sand with a wood backer on sandpaper. very tough to do. I can not do it when I make my segmented blanks with acrylic and aluminum materials combined. I would never been able to sand this blank down evenly and there is no cross contamination involved in it. You would feel all the transition points between materials. Acrylic sand faster than aluminum. Had to use a skew. Just saying.

Last edited:

First thing, I have no idea about stabilizing woods. Never done it never used them. I have used wood hardener for stain purposes and for fixing rot. I will leave that to you. Sanding to 3000 if you can see those difference you have Xray vision my friend. You can feel differences yes but my point is when you put a solid finish coat such as lacquer, poly or CA on wood you will never feel that wood again. Pen Plus is a friction polish and wears off so you will feel the wood and it is thin. But that maybe the look you are after. If you a seeing scratches past 600 grit you are sanding wrong. Just going lengthwise hides those radial scratches by nature. This is why when doing flat work they always say sand with the grain. Now people may not be able to use a skew but they may not also be able to stabilize woods. I think it is easier to learn with a tool that you have anyway. It really is not rocket science. There are so many videos out there to show the proper methods and practice gets you to Carnegie Hall. Do whatever you want but whenever this topic comes up I will always recommend not to sand segmented wood blanks. I sand straight grained woods and do not use a skew at times too. But 600 grit is as high as I go. I top coat with a solid finish. Good luck

Pens Plus does not wear off. LOL There are so many falsehoods parroted on these forums, its why I feel I have to respond. People have an annoying tendency to parrot what someone else said, even when they have ZERO experience with a particular produc.t I have pens I finished years ago with Pens Plus, used every day, that have no signs of wear. Pens Plus is not just a friction polish like any other (there are many, but none contain the microcrystalline was that PP has, which is the magic ingredient.) The wax produces a fingerprint resistant, durable (although not as durable as CA) coating that protects the underlying finish (oil and shellac) from finger oils that would OTHERWISE normally cause a friction polish to break down under use. The wax surface coating prevents that with Pens Plus. I've also tested Pens Plus, in response to another example of reparroted nonsense, by leaving it out in the (very hot 100 degree plus!) sun for a day, and then outside for several days. Supposedly the finish was supposed to have melted and run and become a slimy mess. Pen is still in perfect condition to this day.

FWIW, stabilizing wood is a heck of a lot easier than using a skew. Pour some fluid into a vaccume pressure safe container. Suck out all the air for a few days. Cook in a cheap toaster oven. Not much to it. I bring this up (and have before, in threads where its been said that a skew is the ONLY solution), because not everyone has master-level skill with a skew to achieve these sublimely smooth, sanding-need-not-apply kinds of results. If stabilized wood WILL prevent sanding dust from getting into the grain, then its an option that should be talked about.

Also FWIW, I'm not saying that stabilizing wood is BETTER. All I'm trying to say, is that it might be an option for someone who doesn't have the skew skill to do what you guys are recommending (which again...I agree...is undoubtedly the best option out there, if you have the skill for it.)

I mean, some times...there may just be more than one way to skin the darn cat!

jttheclockman

Member

Jon you are correct there is more than one way to skin a cat and maybe stabilizing is a another way. As I said I never tried it. I did a couple years ago buy a guy's setup when he was moving and never tried it. Can't argue there. The friction pen plus thing I would argue but if it works for you then have at it. Remember one thing everyone's DNA is not the same. We all have oils in our hands. Some more acidic than others and will break down finishes so no one finish is foul proof.

One other point that does not get mentioned but I defy you to try sanding a segmented blank with hard materials such as metal or even plastic when used as separators and sand it flush. Good luck with that. Wood sands faster than hard materials. Even if you sand with a wood backer on sandpaper. very tough to do. I can not do it when I make my segmented blanks with acrylic and aluminum materials combined. I would never been able to sand this blank down evenly and there is no cross contamination involved in it. You would feel all the transition points between materials. Acrylic sand faster than aluminum. Had to use a skew. Just saying.

View attachment 362018

LOL

I think you defined me to do this before. Now, I still have to try using a skew for a blank with metals in it...and, so far, I've not used metals as thick as you have here (BEAUTIFUL pen, BTW, as always.)

I actually do sand pen with metal in them, and yes I do use a wood backer. I tend to sand at a very high speed when I do this, though. Prior to using a strong wood backer, I definitely had problems sanding any blank with metals in it. But with a wood backer, at a high speed, I get level results every time. Blanks with a curvature are harder to deal wtih, as you have to get the wood with the sandpaper perfectly tangential to the points where there are metals, and that can be challenging for sure. Again, the skew is probably the better solution... But I do think it is possible to sand metals level with other materials.

Now, there may be a threshold in terms of metal thickness/quantity, where even with a strong wood backing surface, sanding well isn't possible. I dunno. Its something I'll have to try.

FWIW, I have been working on my skew skill. I've been turning some handles and other wooden tools lately, and all have been made with a skew. I've been working with both strait and radiused skews, trying to get a feel for both. I'm significantly better with the tool now, than I was this time last year. That said, it still seems so much easier to get a catch with the skew. I mean, if you try, you can catch with any tool. With the skew, the tolerance for misplacement/misuse seems much, much smaller. So I haven't been turning anything critical with one just yet. I intend to continue developing my skill with skews though, as I don't doubt that with enough metal (or other hard materials...such as inlace, which I hope to segment with wood and metals soonish here), there may well be cases where sanding just won't cut it.

I have a bunch of christmas trees to turn this weekend. I guess I'll try to turn them all with a skew here, see how it goes.

Signed-In Members Don't See This Ad

leehljp

Member Liaison

It is NOT false, You think too much. Sanding leaves scratches even when viewing with micron microscopes because that is what sanding does; knife edge cutting with razor sharp tools is smoother because that is what knives do. Your premise runs against centuries of knowledge and skill, and wow, you haven't seen Japanese masters at work with knives, scrapers, swords, hand planes etc. Nope, sandpaper doesn't make it as smooth as a sharp edge can when cutting - and I am not talking about sawing. I have personally seen too much to the contrary of your premises.Again...for segmented blanks, I'm not disputing you. My post very explicitly (and I stated as much) disputed only the notion that sanding could NEVER achieve as smooth a result as a tool. This is something you state often, and I'm sorry, but it's false. This is REGARDLESS of the context of turning segmented blanks.

As I already mentioned in my previous post (which you clearly didn't read entirely), I agree that a tool is undoubtedly the better solution to the problem posed in this thread.

IF sanding can make it finer and smoother, why are CNC and machine cuttings done with precision metal cutting edges on blades? By your presumption, they should sand it to make it more smooth.

The right hand plane can cut layers so thin in wood and even end grain that word from a book can easily be read through the ribbons. Sanding would only smear it and introduce scratches. Yep, I have seen it. I used to have a ribbon approx 2 1/2 inches wide and 3 ft long smooth as a baby's behind and clear enough to read a newspaper when the ribbon was laid over it. Knife edge sharp that sandpaper can't improve upon. I'm not making this up for the sake of an argument.

Since you believe that SP can do better than sharp knife edges, do you think that CNC/machining smoothness can be improved by sanding? Let's see now, my micrometer can measure 1/10,000. How was that machined to be able to measure that fine? Hmmm? Oh it was sanded. Nope, machined with very hard steel very precisely! AND this method can be applied to wood without the need for sandpaper.

Last edited: