Fine Engineer

Member

I have an idea for a set of pens I'd like to make for a fundraiser, and one component of that is using wild sage as the primary wood. I have not seen any offered, so I though I'd see how doable this is. I'll document the effort here if anybody else is interested.

I live near a field with lots of sage plants. So I went and cut a couple of branches to clean up and see what the wood looks like. Here is the main branch I started with.

As you can see, there is a fair amount of work getting to the solid bit.

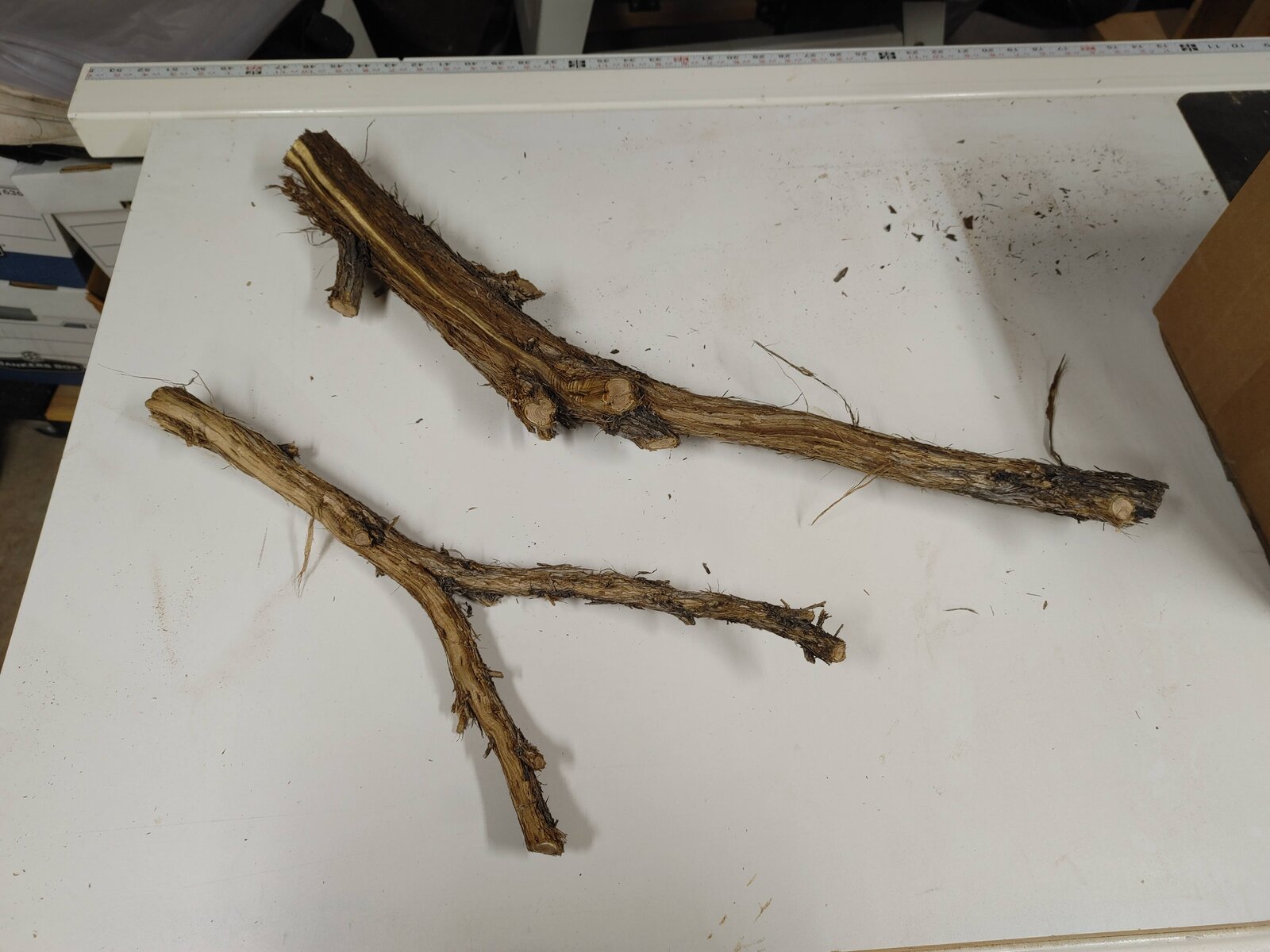

Here's the usable bits after trimming.

And here's what I have after further trimming and debarking.

As of now, I've coated the ends with wax, and these are inside to dry out. I'm thinking this shouldn't take too long as the humidity here is very low, and these are pretty thin. I'm hoping they will not split or crack too much.

I'll add updates as they occur.

I live near a field with lots of sage plants. So I went and cut a couple of branches to clean up and see what the wood looks like. Here is the main branch I started with.

As you can see, there is a fair amount of work getting to the solid bit.

Here's the usable bits after trimming.

And here's what I have after further trimming and debarking.

As of now, I've coated the ends with wax, and these are inside to dry out. I'm thinking this shouldn't take too long as the humidity here is very low, and these are pretty thin. I'm hoping they will not split or crack too much.

I'll add updates as they occur.