robutacion

Member

Hi peoples,

I had a young man at school that contacted me many months ago asking me to help him with his school project/idea. He wanted to create an illuminated lamp that would have wood on each end but a translucent window/cast at its centre.

His original idea was casting some small yellow flowers, positioned with the flower heads at the front of the cast and all around in a circle, his dimensions were 150 round x 50mm thick.

He clearly specified the colour he wanted in the resin, he kept mentioning old yellow swirls see through so that the LED lights positioned on the top/embedded in the wood cap, could how the flowers well...!

We went backs and forwards about what flowers to get and its cost plus the drying process they would require so, and after awhile, he decided that would be better to change that to some type of burl wood outer surface spikes in a shape of a hill/mountain with this translucent yellow swirls going through it, creating an interesting piece when the LED would be turned on.

All of a certain I got a call from this young man, to let me know that, he was now running out of time to complete his project and that other kids were already working on theirs so, he was worry and needed this casting done ASAP. This was last week and I promised it to have it made and posted at the beginning of the following week, he was most happy with that...!:biggrin::wink:

I have had this piece of Peppercorn burl already stabilised for this project, it had to be tall enough so that the top centre of the burl would protrude from the top so that when he drilled thought it to instal the electric wire, the wire couldn't be seen, however, the diameter was a little too small for most burl caps, at 150mm diameter, the average eight wouldn't be any more than 30mm or so, get some that would have this tall bulge, was not easy so, I did hope that I didn't stuff things up as I would run into all sorts of troubles to find another suitable burl piece.

I order the Pearlex powder interference old gold that I didn't have any left when ready to get the mix done, I looked everywhere for a plastic mold that I could use but, I just couldn't find any that would suit so I decided to make one out of a wood bowl blank.

Where I did make a big mistake was to add some gold power I had to the mix to create some extra swirls in the resin but, the whole thing turned to gold/solid colour and have lost most if not all its transparency, I had the feeling that, even before I poured it that I had it wrong but, I didn't have anything else ready, such as pen or knife blanks molds where I could pour that 1 litre of resin mix, I had a bad feeling then and all night I couldn't stop thinking of the damn thing, I wanted to get it out and see how dark/opaque it was...!:frown:

I used the bandsaw to cut it out, the wood bottom was just what I need to mount it on the lathe to finish it.

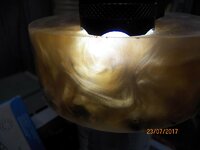

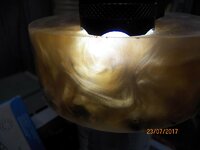

I polished the front face so that I could see exactly what I got, and to demonstrate to this young man that, you could make its surface very shiny, something he was worried about, this polishing would be also needed at the piece top to allow the LED lights to penetrate well. In the next few pics you can see that regardless of what I did (more light, less light) I just couldn't see the wood inside and therefore the cast was useless...!

I was mad as hell, IU should have never added that old gold powder after I had the interference colour in, that would have been more than enough and I should have known better...! :frown:

:frown:

Using a powerful flashlight, I positioned it at the top of the cast hoping that extra light would penetrate the resin but, didn't work, even though and as you will see on the last pic of this batch, a 5mm slice that I cut from the mold in the beginning, there seem to be lots of transparency but in 50mm thick, that was not the case...!

I had no other choice than finding another piece of Peppercorn burl, dry and stabilise it in a hurry, I also had to deal with the mold that I had used before, I had to rebuilt it before I could pour anything on it.

Next, I glued the second burl piece into the mold, it wasn't as tall as the first one, this one was just at the edge of the 50mm but the burl tip was not at the centre...!

My next step was to make a new resin mix and hope that everything was going to turn out as I needed.

What do you guys think, am I going to stuff it up once again...?

Cheers

George

I had a young man at school that contacted me many months ago asking me to help him with his school project/idea. He wanted to create an illuminated lamp that would have wood on each end but a translucent window/cast at its centre.

His original idea was casting some small yellow flowers, positioned with the flower heads at the front of the cast and all around in a circle, his dimensions were 150 round x 50mm thick.

He clearly specified the colour he wanted in the resin, he kept mentioning old yellow swirls see through so that the LED lights positioned on the top/embedded in the wood cap, could how the flowers well...!

We went backs and forwards about what flowers to get and its cost plus the drying process they would require so, and after awhile, he decided that would be better to change that to some type of burl wood outer surface spikes in a shape of a hill/mountain with this translucent yellow swirls going through it, creating an interesting piece when the LED would be turned on.

All of a certain I got a call from this young man, to let me know that, he was now running out of time to complete his project and that other kids were already working on theirs so, he was worry and needed this casting done ASAP. This was last week and I promised it to have it made and posted at the beginning of the following week, he was most happy with that...!:biggrin::wink:

I have had this piece of Peppercorn burl already stabilised for this project, it had to be tall enough so that the top centre of the burl would protrude from the top so that when he drilled thought it to instal the electric wire, the wire couldn't be seen, however, the diameter was a little too small for most burl caps, at 150mm diameter, the average eight wouldn't be any more than 30mm or so, get some that would have this tall bulge, was not easy so, I did hope that I didn't stuff things up as I would run into all sorts of troubles to find another suitable burl piece.

I order the Pearlex powder interference old gold that I didn't have any left when ready to get the mix done, I looked everywhere for a plastic mold that I could use but, I just couldn't find any that would suit so I decided to make one out of a wood bowl blank.

Where I did make a big mistake was to add some gold power I had to the mix to create some extra swirls in the resin but, the whole thing turned to gold/solid colour and have lost most if not all its transparency, I had the feeling that, even before I poured it that I had it wrong but, I didn't have anything else ready, such as pen or knife blanks molds where I could pour that 1 litre of resin mix, I had a bad feeling then and all night I couldn't stop thinking of the damn thing, I wanted to get it out and see how dark/opaque it was...!:frown:

I used the bandsaw to cut it out, the wood bottom was just what I need to mount it on the lathe to finish it.

I polished the front face so that I could see exactly what I got, and to demonstrate to this young man that, you could make its surface very shiny, something he was worried about, this polishing would be also needed at the piece top to allow the LED lights to penetrate well. In the next few pics you can see that regardless of what I did (more light, less light) I just couldn't see the wood inside and therefore the cast was useless...!

I was mad as hell, IU should have never added that old gold powder after I had the interference colour in, that would have been more than enough and I should have known better...!

Using a powerful flashlight, I positioned it at the top of the cast hoping that extra light would penetrate the resin but, didn't work, even though and as you will see on the last pic of this batch, a 5mm slice that I cut from the mold in the beginning, there seem to be lots of transparency but in 50mm thick, that was not the case...!

I had no other choice than finding another piece of Peppercorn burl, dry and stabilise it in a hurry, I also had to deal with the mold that I had used before, I had to rebuilt it before I could pour anything on it.

Next, I glued the second burl piece into the mold, it wasn't as tall as the first one, this one was just at the edge of the 50mm but the burl tip was not at the centre...!

My next step was to make a new resin mix and hope that everything was going to turn out as I needed.

What do you guys think, am I going to stuff it up once again...?

Cheers

George