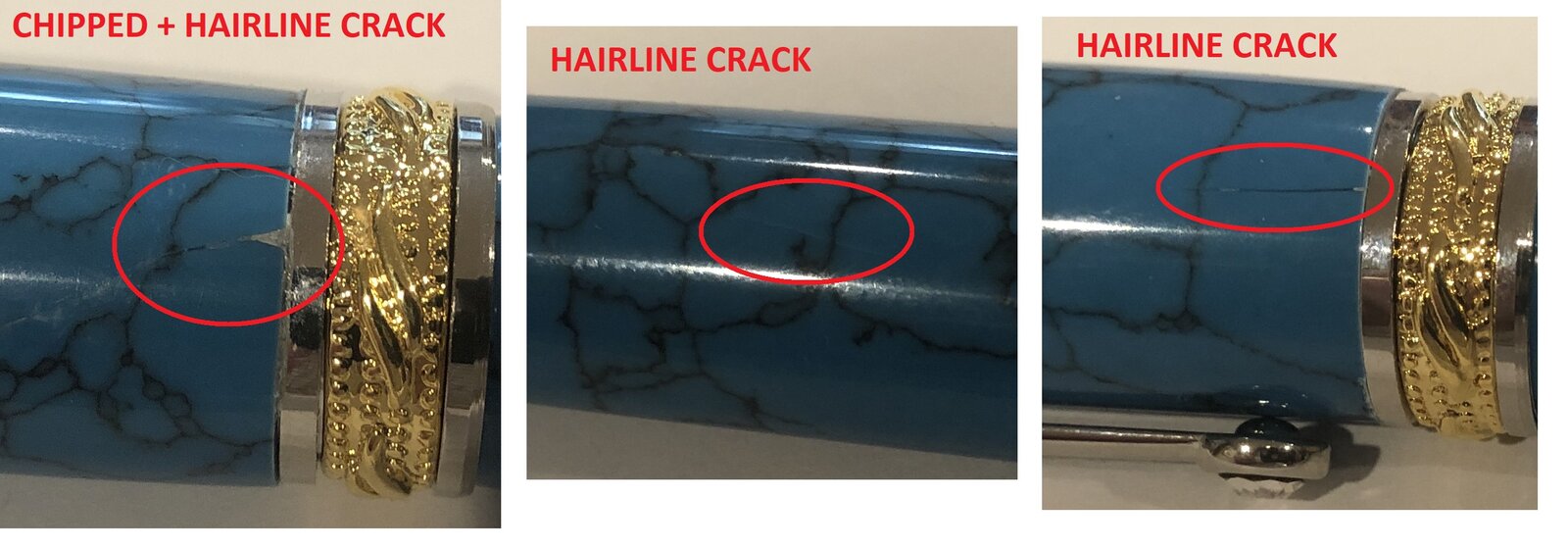

This is a fauxstone pen and a majestic pen kit.

To prepare the blanks for turning, I first CA glued hardwood to the blank to strengthen the blank.

I drilled using 3 or 4 progressively larger bits.

When turning, I used reverse rake tools at 3600rpm.

I believe these problems occurred during turning on the lathe rather than drilling out the core.

My questions are:

(a) any thoughts on how to prevent these problems from occurring?

(b) are there any convincing ways to repair these flaws?

To prepare the blanks for turning, I first CA glued hardwood to the blank to strengthen the blank.

I drilled using 3 or 4 progressively larger bits.

When turning, I used reverse rake tools at 3600rpm.

I believe these problems occurred during turning on the lathe rather than drilling out the core.

My questions are:

(a) any thoughts on how to prevent these problems from occurring?

(b) are there any convincing ways to repair these flaws?