jeporter02

Member

The wood is simple oak, but it was pulled from the Palace of Westminster (aka UK Parliament building, aka The building with Big Ben). It's a gift for a colleague who worked in Parliament. Beaufort ink Leveche pen kit in rose gold. I wanted to add some visual appeal to the oak, so I inlaid abalone shell in the cap and body. Finish is a melamine lacquer, which I prefer on historic wood pens because it provides some lustre and protection to the pen, but preserves the wood "feel" better than CA glue I think. We'll see how the melamine lacquer holds up. This is more of a "keep it on their desk" piece than a "daily use" pen.

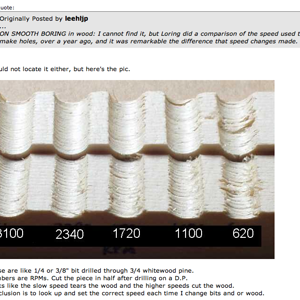

Question for those more experienced: How can I prevent the very minor tear out in the 3 mm holes for the abalone inlay? I realize the key is always cutting with sharp tools to prevent tear out. The drill bit is so small I'm not sure I could effectively sharpen it. Suggestions? Alternatively, if I stabilized the wood with cactus juice, would that help avoid tear out on the edges of the holes? I know it's a small thing. The recipient won't notice, but I do, and I'd love to improve that. (Note the small hole next to the third abalone cabochon is a nail hole from the salvaged wood and not tear out. Initially I thought to hide it in the back, but then I liked the idea of putting some of the history of the blank in the front. If I could do it over again though I'd probably shift the inlay over a bit away from the nail hole. I think it distracts from the inlay.)

Question for those more experienced: How can I prevent the very minor tear out in the 3 mm holes for the abalone inlay? I realize the key is always cutting with sharp tools to prevent tear out. The drill bit is so small I'm not sure I could effectively sharpen it. Suggestions? Alternatively, if I stabilized the wood with cactus juice, would that help avoid tear out on the edges of the holes? I know it's a small thing. The recipient won't notice, but I do, and I'd love to improve that. (Note the small hole next to the third abalone cabochon is a nail hole from the salvaged wood and not tear out. Initially I thought to hide it in the back, but then I liked the idea of putting some of the history of the blank in the front. If I could do it over again though I'd probably shift the inlay over a bit away from the nail hole. I think it distracts from the inlay.)