Ok, I have a brand new universal pen blank squaring jig that I bought new and when it arrived the rod is not square with the base of the angle iron which means to get it square I will need to take the table on my sander out of square. I don't see an adjustment mechanism to be able to do anything about it and don't trust myself to bend it. There isn't anything in the instructions about adjusting it back to square either.

Is there something I'm missing?

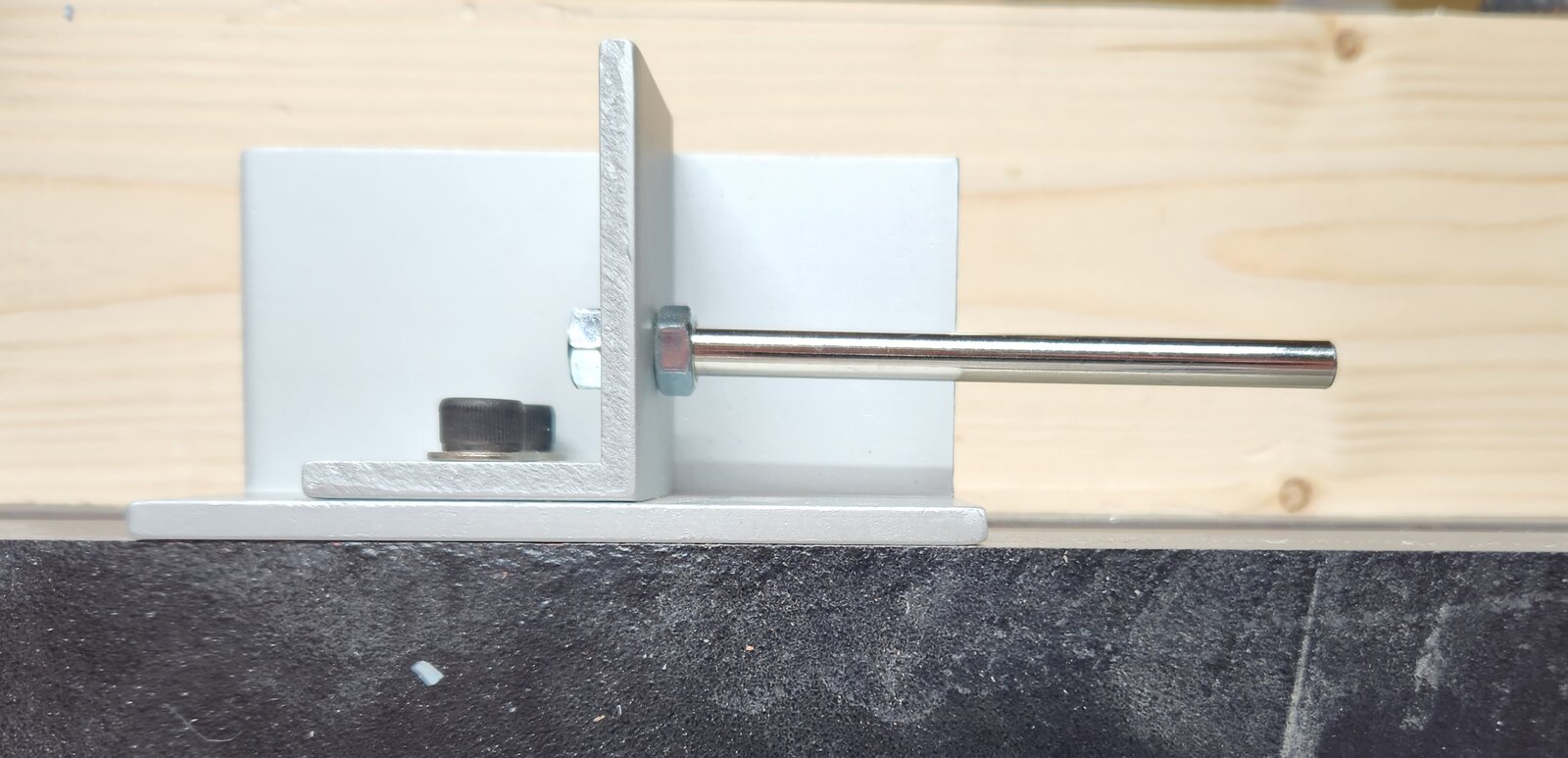

Photo of the jig sitting on my lathe bed for reference below. You can see the right edge of the rod is pointing down.

Is there something I'm missing?

Photo of the jig sitting on my lathe bed for reference below. You can see the right edge of the rod is pointing down.