KDM

Member

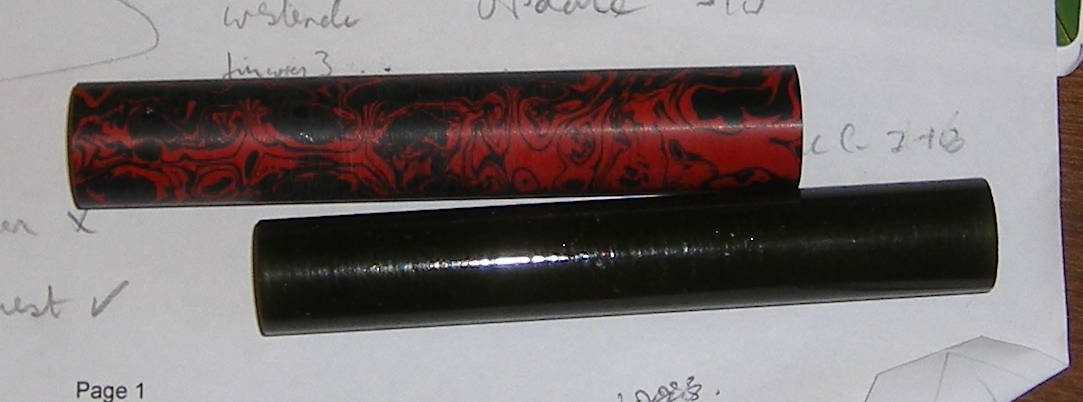

I've cast some PR for the first time. When I turn it, there are shiny gouges in the turning. I'm not sure if these are air bubbles, or if the cutting tool is biting into the material and taking chips out.

Assuming they're not bubbles, I must have the speed wrong. What turning speed woud you lot recommend?

Thanks.

Assuming they're not bubbles, I must have the speed wrong. What turning speed woud you lot recommend?

Thanks.

Last edited: