You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Three snakes

- Thread starter its_virgil

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Kenny Durrant

Member

Nice color and makings. Well Done.

James Smith

Member

Very nice work as usual. They will make very attractive pens with an interesting back story.

Jim Smith

Jim Smith

johncrane

Member

Looking good Don! are you still using the same resin

BULLWINKLE

Member

Coral snake skin would make a beautiful pen. They are reclusive, and way more toxic venom than a rattlesnake.

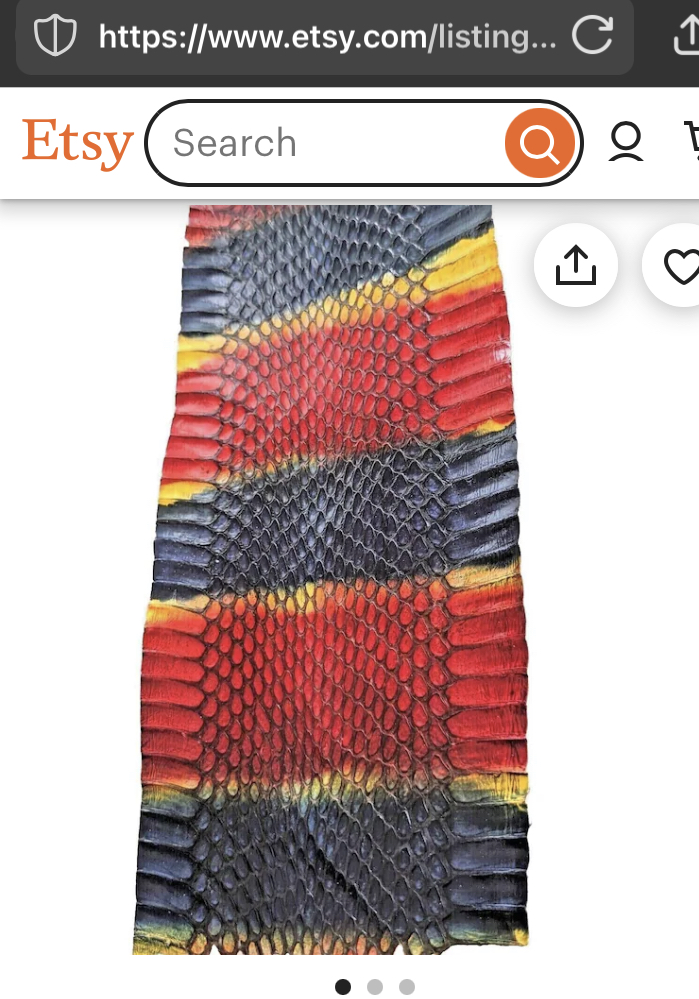

I saw skins for sale on Etsy. About $20

Would definitely make a great looking pen

I saw skins for sale on Etsy. About $20

Would definitely make a great looking pen

keithkarl2007

Member

Awesome. Are these typically done for short tubes or could they be made for a pen like the Zen?

its_virgil

Member

They can be made for pens with longer tubes such as the zen.Awesome. Are these typically done for short tubes or could they be made for a pen like the Zen?

its_virgil

Member

I've had one coral skin since I've been making these blanks(20+yrs) and yes, they do make nice looking pens.Coral snake skin would make a beautiful pen. They are reclusive, and way more toxic venom than a rattlesnake.

I saw skins for sale on Etsy. About $20

Would definitely make a great looking pen

its_virgil

Member

Thanks John. I still use polyester resin (Silmar 41) for snake skin casting. I tried several of the popular epoxy casting resins but the clear will yellow over time. Yellowed blanks are difficult to sell. The epoxy resins were no problem to cast. I tried the Alumilite Urethane resins (Clear and clear slow) but the urethanes did not play well with the snake skins. Not sure why. I just could not get the quality of casting I desired. No problem casting labels with the urethane resins.Looking good Don! are you still using the same resin

Don

ZanderPommo

Member

That skin is tanned. Untanned skins work far better. Essentially the best thing you can use is a skin that was cleaned, stretched, and dried. It's important to first scrape off the clear top scales. Any scales you miss will trap air and look "shiny". Most if not all tanned skin reacts with the resin and won't come out nice. It will also produce bubbles, specifically when not cast under pressure.Coral snake skin would make a beautiful pen. They are reclusive, and way more toxic venom than a rattlesnake.

I saw skins for sale on Etsy. About $20

Would definitely make a great looking pen

View attachment 363210

ZanderPommo

Member

Very nice

ZanderPommo

Member

They can be done on any tube, for the most partAwesome. Are these typically done for short tubes or could they be made for a pen like the Zen?

its_virgil

Member

Yes the skin I use is "tanned" what ever that means. After thoroughly cleaning the skin the skin is soaked in a "relaxing " solution of 50% isopropyl alcohol(99%) and glycerin. After about an hour in the solution the skin is loosely rolled and stored in a freezer bag for a few days. The skin is soft and pliable and is much like t-shirt material. Other "tanning" solutions are available but some will react with the tanning solution. Before casting I wipe down the skin with lacquer thinner to remove as much of the solution as possible. I have not experienced any problems with skins treated with this solution. I have experienced problems with skins tanned with other solutions and I will not use a skin tanned with other methods. The scale flaps or covers are removed prior to casting.That skin is tanned. Untanned skins work far better. Essentially the best thing you can use is a skin that was cleaned, stretched, and dried. It's important to first scrape off the clear top scales. Any scales you miss will trap air and look "shiny". Most if not all tanned skin reacts with the resin and won't come out nice. It will also produce bubbles, specifically when not cast under pressure.

Skin that is stretched and air dried is not my favorite to use. The skin is dry and stiff, much like parchment paper (or worse), and I find it difficult to get the stiff skin glued to the tube. This has been my experience with stretched and air dried skin.. Air dried skin works nicely for gluing to flat surfaces such as belts but hot so much for wrapping around the small tubes we use for pen kits.

Do a good turn daily!

Don

ZanderPommo

Member

Yes, I should've been more specific. I mainly use skins from very small snakes as I believe the pattern shows up a lot better on a small piece like a pen. For larger snakes using a glycerin solution makes things a lot easier. A full-size diamondback for instance, would be as you described, far too rigid to work around the tube. The smaller the snake, the thinner the skin, so air drying to me is preferable. What I was referring to is the commercial tanning process that leaves the skin resulting in a leather like form, usually having a suede feel to the back side. That won't cast well. There is a "technical" process for tanning snakeskin into leather, though a lot of people refer to your glycerin/alcohol treatment as "tanning". That form doesn't cause issues. If you buy the snake "leather" from commercial sources, it will usually produce bad results.Yes the skin I use is "tanned" what ever that means. After thoroughly cleaning the skin the skin is soaked in a "relaxing " solution of 50% isopropyl alcohol(99%) and glycerin. After about an hour in the solution the skin is loosely rolled and stored in a freezer bag for a few days. The skin is soft and pliable and is much like t-shirt material. Other "tanning" solutions are available but some will react with the tanning solution. Before casting I wipe down the skin with lacquer thinner to remove as much of the solution as possible. I have not experienced any problems with skins treated with this solution. I have experienced problems with skins tanned with other solutions and I will not use a skin tanned with other methods. The scale flaps or covers are removed prior to casting.

Skin that is stretched and air dried is not my favorite to use. The skin is dry and stiff, much like parchment paper (or worse), and I find it difficult to get the stiff skin glued to the tube. This has been my experience with stretched and air dried skin.. Air dried skin works nicely for gluing to flat surfaces such as belts but hot so much for wrapping around the small tubes we use for pen kits.

Do a good turn daily!

Don

Woodchipper

Member

Seems like that could be a market for the big pythons found in Florida. That would be a really big pen.

James Smith

Member

Unfortunately, very large snake skins do not make really attractive pens no matter which species it is. When the pattern is too large, it just shows blobs of different colors. I my experience, snakes about 24 to 30 inch long see to work the best.Seems like that could be a market for the big pythons found in Florida. That would be a really big pen.

Woodchipper

Member

Interesting. James Smith, I'll make sure I carry a tape measure with me. "Nope. You are too short."

James Smith

Member

I've made several snakeskin pens mainly from roadkill Copperheads. I would not kill a snake to get a skin to make pens. Now that we've moved to central Florida where there are no Copperheads, I have a friend in Georgia who keeps and eye out for them and freezes them to keep for me when I get up that way.Interesting. James Smith, I'll make sure I carry a tape measure with me. "Nope. You are too short."

WOOW.... Now THAT is a snake skin! Imagine that in a pen...Coral snake skin would make a beautiful pen. They are reclusive, and way more toxic venom than a rattlesnake.

I saw skins for sale on Etsy. About $20

Would definitely make a great looking pen

View attachment 363210