Kalai

Member

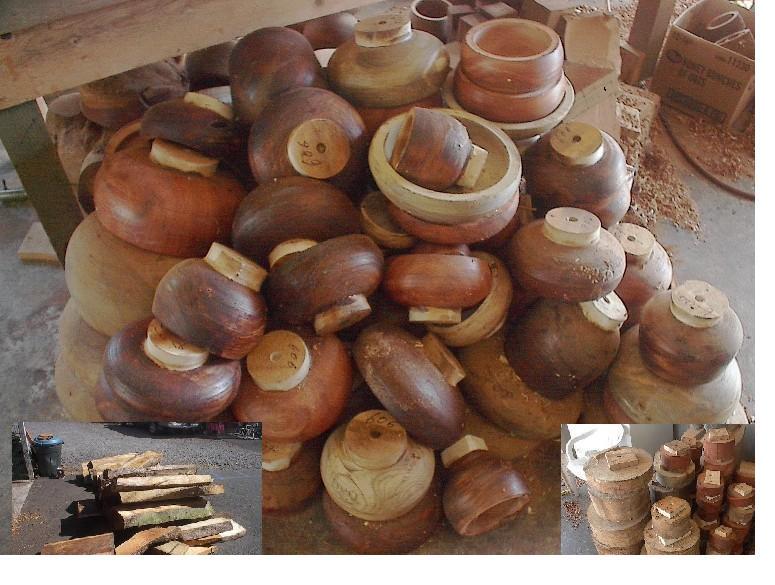

Hi, this is how I make 6000 bowls per year.

I start by milling the wood on my woodmiser bandsaw mill, then I draw circles on the wood and cut the rounds out on my bandsaw, then I glue a waste block onto the round and let it dry for a day or 2, I use Weldwood Plastic resin glue. Then I rough cut each bowl to just under 1 inch thick and let it dry for 3-6 months depending on the size of the bowl and the wood.

I then take the dry rough cut bowl and finish cut the bowl to the final thickness of a bit less than 1/4 inch, I sand the outside with a air powered random orbital sander going through the grits, I sand the outside of the bowl before I finish carve the inside of the bowl, after carving the inside I sand the inside just a bit on the lathe and the rest of the way off the lathe using a high speed spindle sander going through the grits after that I cut off the waste block and I sand the bottom of the bowl with a inflatable drum sander then I buff the bowl, oil it with mineral oil and it is done.

I do use a special process for finishing the bowls and it requires me to seal the bowls with a sanding sealer between each grit in the sanding process. I mostly make Hawaiian calabash bowls and I use a Ellsworth bowl gouge to carve the bowls.

In this process it is important to start the circle of rough cutting and finish cutting, you need to have a stock of rough cut bowls before you start finishing the bowls, once you get enough rough cuts then you can start the cycle of roughing and finishing the bowls.

I will rough cut about 40-50 bowls a day for a month (they range in size from 4 inches in dia. to 18 inches in dia.) and then finish cut for a month and then rough cut and then finish cut and so on. this is in a nut shell and there is tricks that I use to help speed things up but it also helps when you have been turning since you were 12 years old. If any of you have any questions let me know, if anyone ever gets to the Big Island of Hawaii I offer classes free to IAP members.

The picture shows the Milled wood and the glued rounds and the rough cut bowls.

I start by milling the wood on my woodmiser bandsaw mill, then I draw circles on the wood and cut the rounds out on my bandsaw, then I glue a waste block onto the round and let it dry for a day or 2, I use Weldwood Plastic resin glue. Then I rough cut each bowl to just under 1 inch thick and let it dry for 3-6 months depending on the size of the bowl and the wood.

I then take the dry rough cut bowl and finish cut the bowl to the final thickness of a bit less than 1/4 inch, I sand the outside with a air powered random orbital sander going through the grits, I sand the outside of the bowl before I finish carve the inside of the bowl, after carving the inside I sand the inside just a bit on the lathe and the rest of the way off the lathe using a high speed spindle sander going through the grits after that I cut off the waste block and I sand the bottom of the bowl with a inflatable drum sander then I buff the bowl, oil it with mineral oil and it is done.

I do use a special process for finishing the bowls and it requires me to seal the bowls with a sanding sealer between each grit in the sanding process. I mostly make Hawaiian calabash bowls and I use a Ellsworth bowl gouge to carve the bowls.

In this process it is important to start the circle of rough cutting and finish cutting, you need to have a stock of rough cut bowls before you start finishing the bowls, once you get enough rough cuts then you can start the cycle of roughing and finishing the bowls.

I will rough cut about 40-50 bowls a day for a month (they range in size from 4 inches in dia. to 18 inches in dia.) and then finish cut for a month and then rough cut and then finish cut and so on. this is in a nut shell and there is tricks that I use to help speed things up but it also helps when you have been turning since you were 12 years old. If any of you have any questions let me know, if anyone ever gets to the Big Island of Hawaii I offer classes free to IAP members.

The picture shows the Milled wood and the glued rounds and the rough cut bowls.