Agree with Edgar - looks like a drawbar rather than a knockout bar.

First, don't beat yourself up - we've all done something like this. Fortunately, there are a number of solutions, some obscure, and at least one that is very obvious.

First, the more obscure solutions:

1. Put the chuck key into the chuck, and then use it to apply leverage to break loose the stuck taper. However, be aware that the jacobs chuck mandrel is double-ended - a Morse Taper on one end (the end that is stuck in the headstock spindle), and a JT33 taper on the other end. Applying leverage using the chuck key could just break loose the JT33 taper which removes the chuck, but leaves the mandrel stuck in the headstock spindle.

2. A variation on that idea - open the jaws of the chuck, and insert something between them that can be used to lever the chuck free. This is a common solution when the chuck that is stuck is a scroll chuck (a problem that we have all had). But again, the the problem is that trying to break things loose by applying leverage to the chuck could break loose the JT33 taper rather than the MT taper.

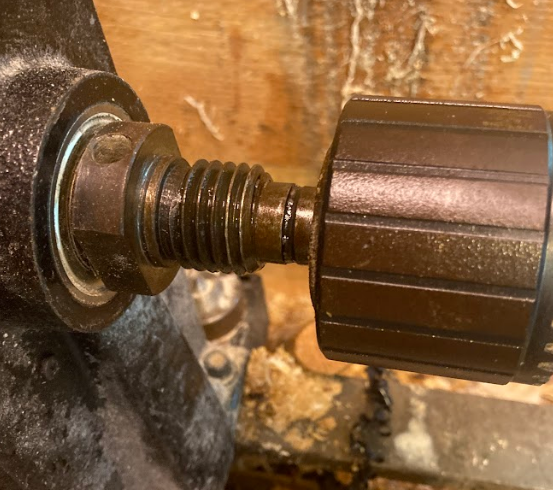

But the best solution is the simplest - using the wooden mallet that you should have permanently stored at the headstock of the lather, just tap the end of the drawbar as it comes through the handwheel. Realistically, the difference between a drawbar and a knockout bar is that the diameter of a drawbar is smaller, and the end is threaded to screw into the end of the morse taper on the jacobs chuck. But if the chuck is stuck - tapping on the end of either has the same effect - it loosens the morse taper.

In fact, when I made my drawbar, I made a threaded HDPE cap that fits on the outboard end. That cap serves two functions. First, it makes the end of the drawbar smooth so that I don't gouge my hand when I grab the handwheel. After you have done that a few times, you get the message why that is important. Second, it provides a smooth, hard plastic surface that I can tap if I get carried away when tightening the drawbar and pull the morse taper in so far that it gets stuck.

And you say you don't have a mallet stored at the end of the lathe - - - why not? If you are a wood turner, you can easily make one from a scrap of firewood.