Well this was harder than I thought, explaining such a simple design. I'm no engineer, but I can usually draw a three dimensional diagram well enough to convey what I want. I resorted to photos. Just let me know if you have questions. These were easy to make. There are 5 cuts of wood.

I bought some .5"x1.5"x24" boards, and some flat stock 3/8"x6"x24" boards. And I used some 5/16" dowels I had laying around.

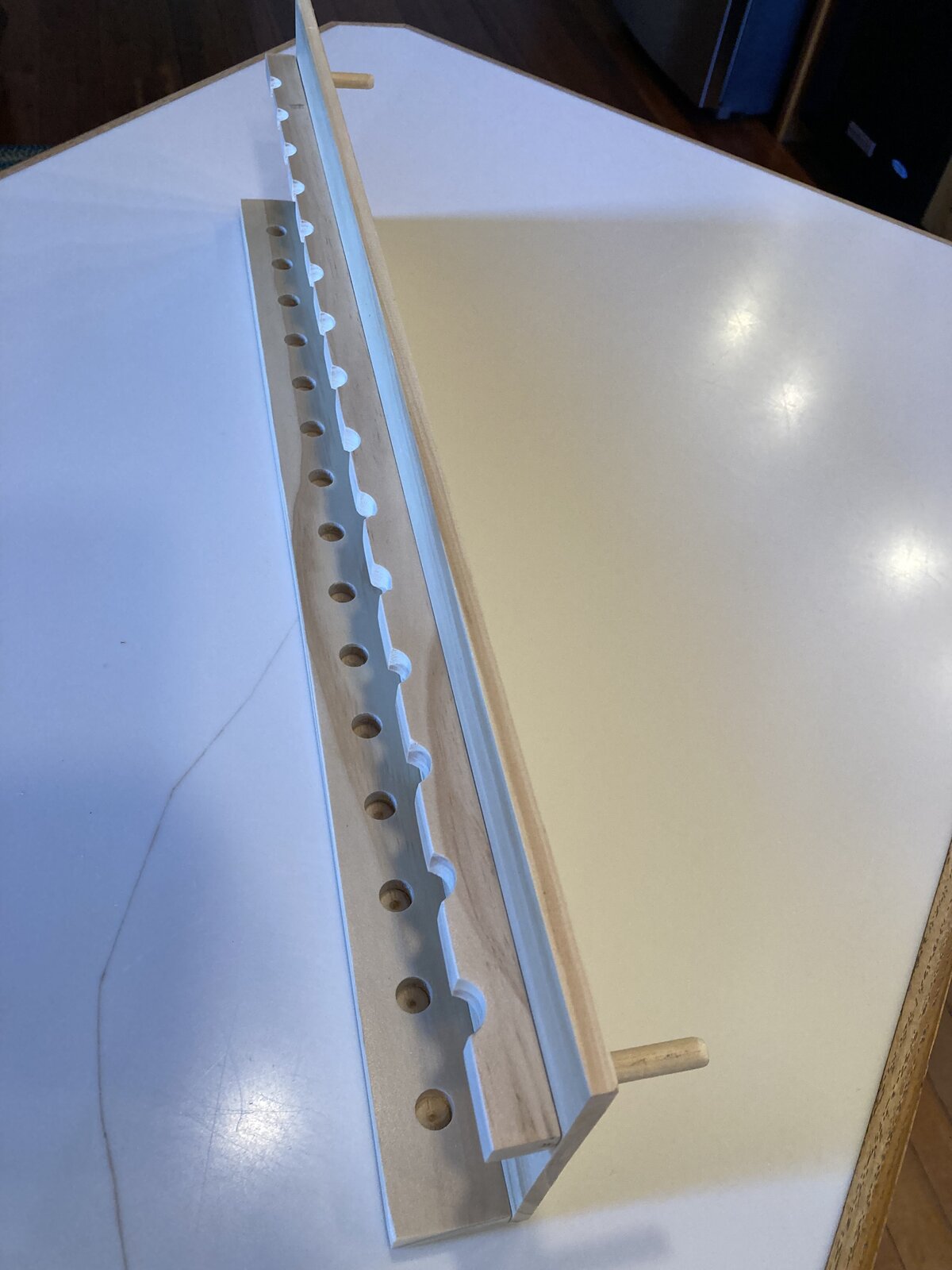

I took one of the half inch boards and marked it every 1.5" and drilled all the way through on the drill press. I used a 5/8" forstner bit (I recently bought this

Wen set for ~$50). The spacing seems good and the diameter of the cradle is good too. Probably put some blue tape under the board to minimize blowouts because the bottom is going to show on half. I then ripped the board down the center on the table saw to create two cradles.

I took another half inch board and marked it every 1.5" and drilled 3/4 the way through for my base. I used different sizes for the pens I wanted to display. Half inch for rollerballs, and quarter inch for sierras which I decided to display tip down. Just measure the size of the pens and make sure they fit.

Then I set up a stop on my new

drill press fence (also $50) and drilled a hole for the dowels into/through all my boards. On the ends you want to be about 5/8" from the ends. I didn't really plan for this-- I just drilled into a spot and it turned out the ends lined up later. I figured there would be overhang but they turned out flush (at that point I was also planning on 4 legs). The stop ensures the holes stay lined up, but let's be honest, it's going to be imperfect anyway. I ended up sanding my dowels a little thinner because a tiny bit of wonk makes it hard to line up. I deliberately made the middle hole off-center, which helps make sure it's going together the same way each time. You'll see that I added color-coordinating dots to each of the 4 stands I used once I got things looking happy. At this point you've got your display rack and it just needs some legs.

I cut some lengths of the half inch boards at a 45 for the back legs. Leave the legs a half inch longer than you need for now. Then I drilled them all the way through from the back side by placing the 45 cut flat down on my drill press table. Pro tip: after the first one I drilled some smaller starter holes with a hand held drill to keep the bit from wandering downhill since you're drilling into an angle.

In the photo, that's just scrap wood for demo purposes. Yours won't be 45 at both ends. Moving on...

I used another piece of the 6" flat stock and cut some right triangles to dress up the end of the stand and glued them to my legs. Notice that you'll want a right and left end with the triangles on the outside. Once the glue set I took them to the disk sander and sanded off the extra length. It was easier to just make it big and sand to fit than to spend time cutting stuff perfect and keeping it lined up when gluing. For me anyway.

Leave all the dowels long, and glue them into the notched/cradle boards at the front. I was tempted to cut them to "fit" the length of the holes, but having them stick out the back makes disassembly a lot easier. Just push from the back with your thumb, as long as they're not too tight. If you're going to glue it permanent, then I'd cut/sand it flush.

At this point I called it done and proceeded on to finish.

I'll point out that the triangle ends are only anchored at one place at this point. There is enough friction in the setup that it's pretty stable, but it can "fall over" if the legs both pivot the same direction. The triangles do bump into the dowels and tend to not be able to both pivot the same way. Easy fix is to use your scrap and cut two more tiny legs for the lower dowels. Unfortunately, I already cut my dowels a tad too short for this. But if I make more, I'll leave the dowels longer and add front legs. The easiest way would be to assemble the whole thing, flip it over, slide on the extra front legs onto the dowels, and that's the exact lineup to glue it to the end triangles.

Here's what I mean by the leg pivoting out. It happened when I was sliding the display to a new spot while full of pens, and no pens fell out. It can't actually fall over, just become unlevel until you put the foot back under it.

Happy building!