triw51

Member

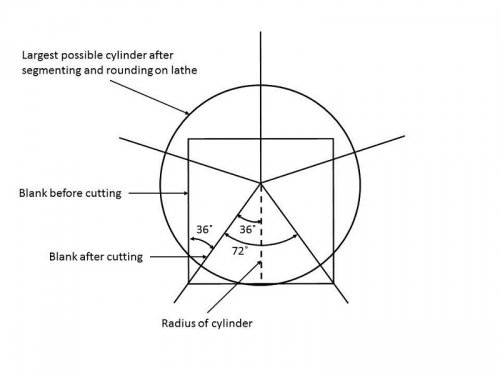

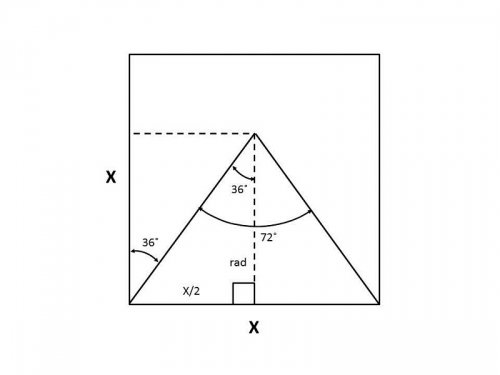

I have some 1" square blanks I would like to segment into a pepper mill. The wood is iron wood with little to no figure in it. I would like to use 5 pieces with thin maple strips seperating the iron wood.

My question is do I divide 360 degrees by 5 and cut my iron wood to that angle (which is 72 degrees) or do I subtract 72 from 90 and cut at 18 degrees?

I have not done this before and not sure how to figure the angle of that cut. Thanks in advance for any help

My question is do I divide 360 degrees by 5 and cut my iron wood to that angle (which is 72 degrees) or do I subtract 72 from 90 and cut at 18 degrees?

I have not done this before and not sure how to figure the angle of that cut. Thanks in advance for any help