Wmcullen

Member

I'm not sure if this process is right or wrong; unique or common. But I want to share in case it's interesting. |

29: Scribe Tool for Octagon Cuts

last post- 28: Cutting Corners with Bandsaw

(3d *.obj file attached)

Thanks for the GREAT discussion on the utility and methods of turning pen blanks into octagons.

I have one more simple tool to contribute if you want to go a step beyond "eyeballing" the necessary cuts.

The Problemlast post- 28: Cutting Corners with Bandsaw

(3d *.obj file attached)

Thanks for the GREAT discussion on the utility and methods of turning pen blanks into octagons.

I have one more simple tool to contribute if you want to go a step beyond "eyeballing" the necessary cuts.

While my last jig focused on making 45 degree cuts in blanks, it failed to indicate where to make the cuts if you want an octagon.

I may have accidentally cut one squared blank into a smaller square. (Doh!!)

A better octagon should have all sides (S) equal, but I wasn't sure where to cut.

My Solution

(Not rocket surgery... but a bit of geometry.)

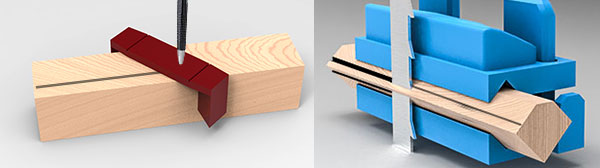

I started by building a simple "center finding" scribe tool... and modified it by offsetting the scribing hole to 29.29% of the length and replacing the more common rounded ends with triangles. I made the scribing hole just big enough for a mechanical pencil.

Why 29.29% across?

This school website provided the main equations.

Summary

Because we typically deal with smaller blocks of wood in penturning, this tool is designed to handle blanks with side measurements from 5/8" to 1" wide.

Cutting at 45 degrees along this line should yield a perfect octagon.

I've attached a 3d *.obj file called octFinder3.obj. I always need to scale it up by 10x before printing. Model offered as-is.

Thanks for looking

- Cullen

Attachments

Last edited: