rixstix

Member

Comments, critique, suggestions for improvement, questions, etal are welcomed and appreciated. The backstory is below the pics.

Next rev: lower taper to 1 degree/2degrees to reduce the visual taper.

Story behind the tapered cap/body connection

I've always leaned toward unconventional ideas. In my beginning trek into the world of kitless pens, my budget didn't allow for various triple start taps/dies and I wasn't satisfied with single start threads. In all my brainstorming sessions, the best I could come up with was using O-rings somewhere. Teeny magnets quickly found their way to the 'bad idea' list.

A friend was visiting from Australia who is a Bosch engineer/machinist (not that this matters) who offered to give me a few tips on my relatively new metal lathe. I asked him to put on his thinking cap about my project and he quickly poo-poo'd the o-ring idea. After a couple of days, he proceeded to show me how to use the lathe to 'bore'. Then he planted the seed by showing me how to make a perfectly matched taper on some bottle stopper blanks. From there, the light bulb clicked. He had given me enough information for solving the problem on my own.

A 2 degree/4 degree included angle forms a locked taper. I made a couple of custom finials so that I could attach the cap and body to my homemade tensile strength tester to measure the force needed to separate the cap/body. That ranged between 5 and 10 pounds which seems more than sufficient. The next test was using another custom finial so that I could attached an air fitting to see/prove that the connection was 'bubble' tight. I used a bicycle pump and stopped at about 15 psig and no air bubbles in soapy water.

Scratch testing is still in progress but I have not detected any scratching on the pen that I've been using for a couple of months now.

I realize unthreaded cap/body is unconventional and will never make it to mainstream penmaking but it meets my needs while satisfying the budget. I may drop down to 1 degree/2degree angles to reduce the visual angle on the body.

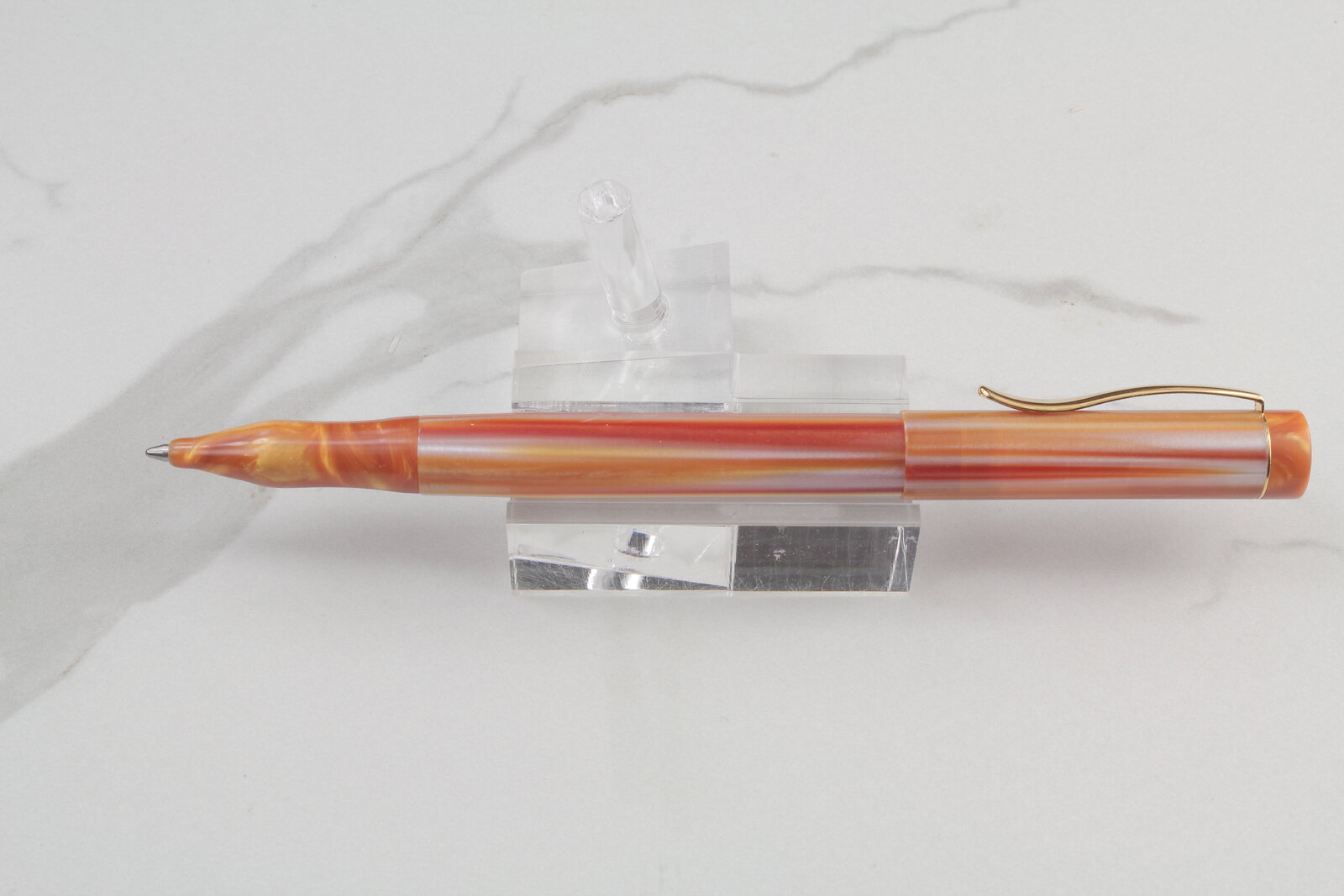

- Pen cap OD: 12.7mm ( 1/2")

- Cap wall: 0.60 mm (.024") ( I think I can still go a bit thinner)

- Body OD: 12.0 mm

- Taper 2 degrees/4 degrees included

- Cap/Body separation force required: 5 to 9 pounds

- Cap/Body air seal: bubble tight to 15 psig

- Cap/Body seals by push, twist left or twist right

- Refill P900/Parker

- Clip robbed from Polaris kit

Next rev: lower taper to 1 degree/2degrees to reduce the visual taper.

Story behind the tapered cap/body connection

I've always leaned toward unconventional ideas. In my beginning trek into the world of kitless pens, my budget didn't allow for various triple start taps/dies and I wasn't satisfied with single start threads. In all my brainstorming sessions, the best I could come up with was using O-rings somewhere. Teeny magnets quickly found their way to the 'bad idea' list.

A friend was visiting from Australia who is a Bosch engineer/machinist (not that this matters) who offered to give me a few tips on my relatively new metal lathe. I asked him to put on his thinking cap about my project and he quickly poo-poo'd the o-ring idea. After a couple of days, he proceeded to show me how to use the lathe to 'bore'. Then he planted the seed by showing me how to make a perfectly matched taper on some bottle stopper blanks. From there, the light bulb clicked. He had given me enough information for solving the problem on my own.

A 2 degree/4 degree included angle forms a locked taper. I made a couple of custom finials so that I could attach the cap and body to my homemade tensile strength tester to measure the force needed to separate the cap/body. That ranged between 5 and 10 pounds which seems more than sufficient. The next test was using another custom finial so that I could attached an air fitting to see/prove that the connection was 'bubble' tight. I used a bicycle pump and stopped at about 15 psig and no air bubbles in soapy water.

Scratch testing is still in progress but I have not detected any scratching on the pen that I've been using for a couple of months now.

I realize unthreaded cap/body is unconventional and will never make it to mainstream penmaking but it meets my needs while satisfying the budget. I may drop down to 1 degree/2degree angles to reduce the visual angle on the body.

Last edited: