ramaroodle

Member

Wasn't sure if I should start a new thread as this was part of another thread I started when I was looking into clear-casting but it lead me down this path so I thought I'd share. Wayne, not sure if this qualifies as a tutorial or not but I can redo it when I get to the end of the journey.

I received my pack of ten "sublimation pens" from Amazon yesterday. (It's cool living in Seattle where at 1 am I can order those pens and they are on my porch when I wake up in the morning!) I had no intention of using anything but the tubes. After looking at them I have a better understanding of what is needed. Those tubes are smooth, white and coated by some mass production machine in Asia. I can't reproduce that. I bought a little open-box Canon SELPHY printer for $40 on eBay which was probably a waste of money for my purposes.

So, here's what I've done so far.

I already had some 2"x4" Avery brand address labels (#8163) so I started out with them. I also ordered different Avery label material types. Of the types I ordered these seemed to work the best. When printed they produced a nice, crisp, glossy label.

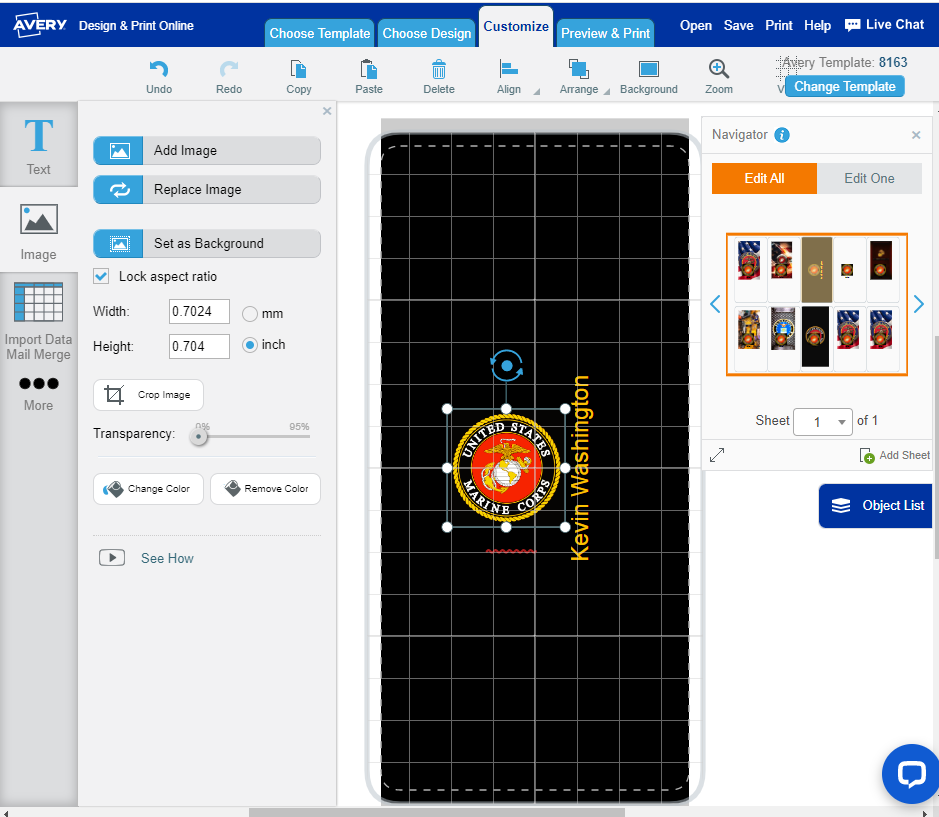

Using the Avery app for the #8163 2x4 address labels made the exact sizing and manipulation of these to within a hundredth of an inch a snap, so the wraps are perfectly sized at pi times the diameter of the tube which Alexa takes 2 seconds to tell me.

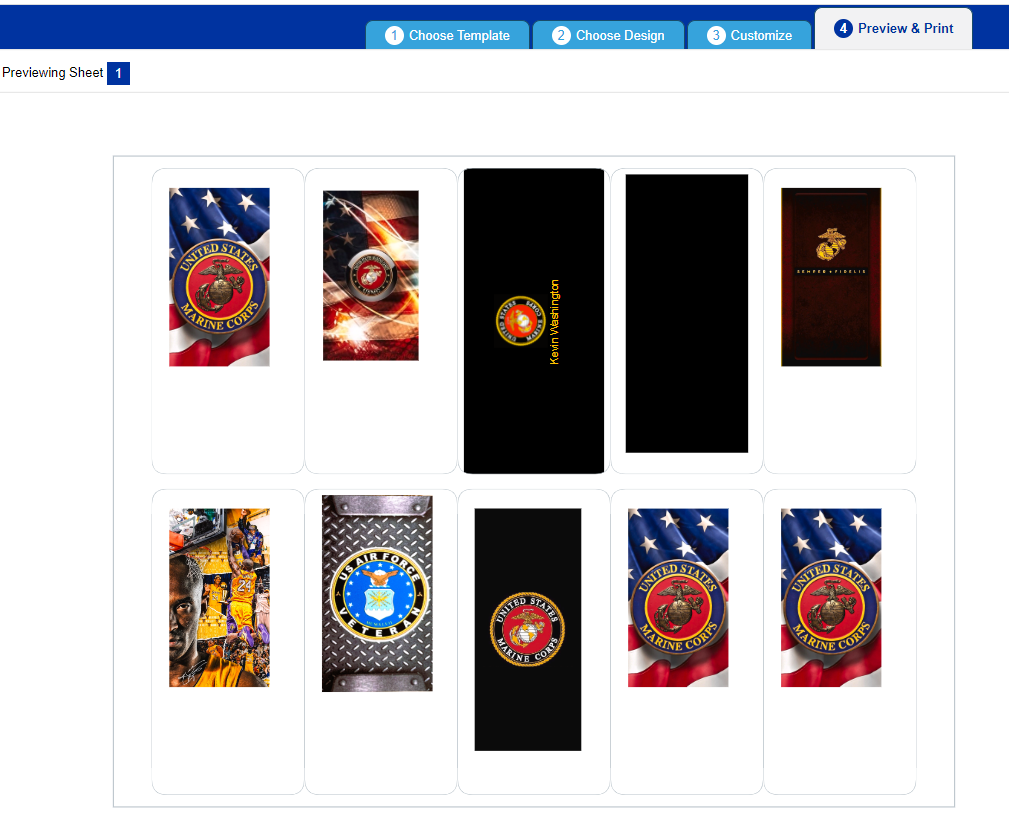

The sticker paper is just a full sheet so instead of putting the address labels in the printer I put the Sticker Paper sheet in and the app produces a pdf to print.

From there I simply cut them out and wrapped the tube. For the best results, the tube should be painted white.

The original rabbit hole goal was to be able to do a "clear cast" style pen. I haven't gotten to that stage yet but I'm thinking that I can either paint the bare tube glossy white and wrap it and then clear cast it or like in this first trial run I just painted the bare wood white and gave it a double coating of my GluBoost finish. I bought a pre-owned Underhill cast set-up from a member that arrived yesterday so getting that to work is the next step. This first test isn't ready for prime time but I can see a light at the end of the tunnel. I wanted vibrant, glossy graphics without breaking the bank and this technique seems to have potential and offer some interesting variations.

Don't know if this qualifies as a tutorial yet as the goal is to clear-cast but this is what I've done while gathering the tools, materials and skills to do that.

This also gives me another easy method of personalizing a pen or batch of pens with logos. Also, those "sublimation" pens from Amazoo are only $1.50 each so I'm good with harvesting the sleeve and tossing the guts. A 3/8" pen tube slides inside that smooth aluminum sleeve which is perfect and easy to wrap to be made into any of the popular pens using a 3/8" tube.

I received my pack of ten "sublimation pens" from Amazon yesterday. (It's cool living in Seattle where at 1 am I can order those pens and they are on my porch when I wake up in the morning!) I had no intention of using anything but the tubes. After looking at them I have a better understanding of what is needed. Those tubes are smooth, white and coated by some mass production machine in Asia. I can't reproduce that. I bought a little open-box Canon SELPHY printer for $40 on eBay which was probably a waste of money for my purposes.

So, here's what I've done so far.

I already had some 2"x4" Avery brand address labels (#8163) so I started out with them. I also ordered different Avery label material types. Of the types I ordered these seemed to work the best. When printed they produced a nice, crisp, glossy label.

Using the Avery app for the #8163 2x4 address labels made the exact sizing and manipulation of these to within a hundredth of an inch a snap, so the wraps are perfectly sized at pi times the diameter of the tube which Alexa takes 2 seconds to tell me.

The sticker paper is just a full sheet so instead of putting the address labels in the printer I put the Sticker Paper sheet in and the app produces a pdf to print.

From there I simply cut them out and wrapped the tube. For the best results, the tube should be painted white.

The original rabbit hole goal was to be able to do a "clear cast" style pen. I haven't gotten to that stage yet but I'm thinking that I can either paint the bare tube glossy white and wrap it and then clear cast it or like in this first trial run I just painted the bare wood white and gave it a double coating of my GluBoost finish. I bought a pre-owned Underhill cast set-up from a member that arrived yesterday so getting that to work is the next step. This first test isn't ready for prime time but I can see a light at the end of the tunnel. I wanted vibrant, glossy graphics without breaking the bank and this technique seems to have potential and offer some interesting variations.

Don't know if this qualifies as a tutorial yet as the goal is to clear-cast but this is what I've done while gathering the tools, materials and skills to do that.

This also gives me another easy method of personalizing a pen or batch of pens with logos. Also, those "sublimation" pens from Amazoo are only $1.50 each so I'm good with harvesting the sleeve and tossing the guts. A 3/8" pen tube slides inside that smooth aluminum sleeve which is perfect and easy to wrap to be made into any of the popular pens using a 3/8" tube.

Last edited: