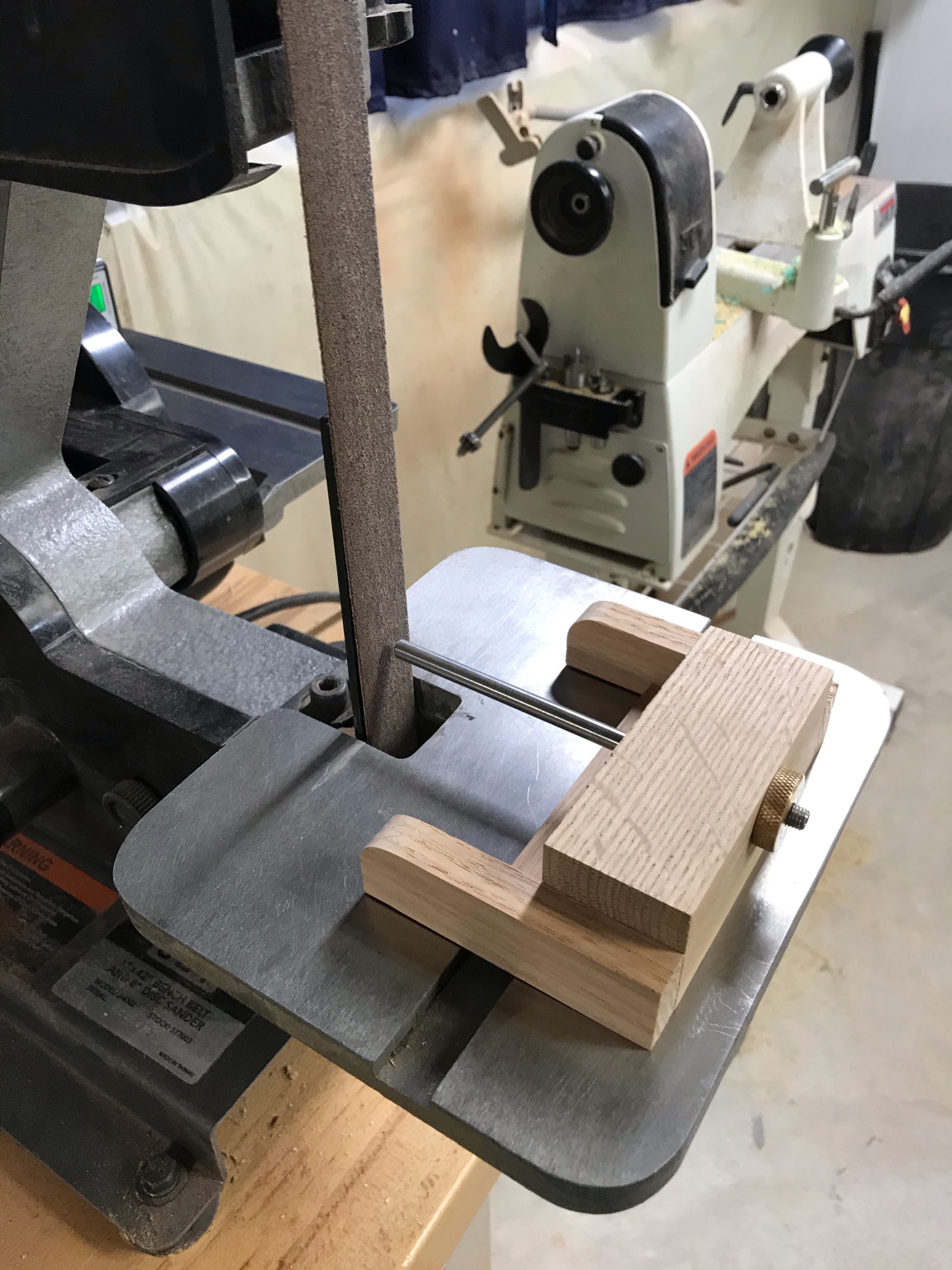

I got inspired by WriteOn in another post he created using a Sorby ProEdge for squaring pen blanks. A few years ago , I bought a Jet 1 x 42 inch belt sander, it has an 8 inch disc sander on the side. I really didn't buy it for that feature and never really used it, as I have a 12 inch sander I use. Well I have been trying to think of a squaring jig that didn't require a lot of setup. My wife bought me a lathe mounted one, that I have been using and to be honest it works great. It just has to be setup each time. I had the sleeves and an old pen mandrel and a few little small pieces of oak. I first made sure the sander was setup square in both directions. The hole I drilled was off just a very small amount, so I put in a couple set screws on the bottom so I can adjust the zero angle if need be. The jig fits both the disc sander side as well as the belt sander side. Here's what I came up with.

Sent from my iPhone using Penturners.org mobile app

Sent from my iPhone using Penturners.org mobile app