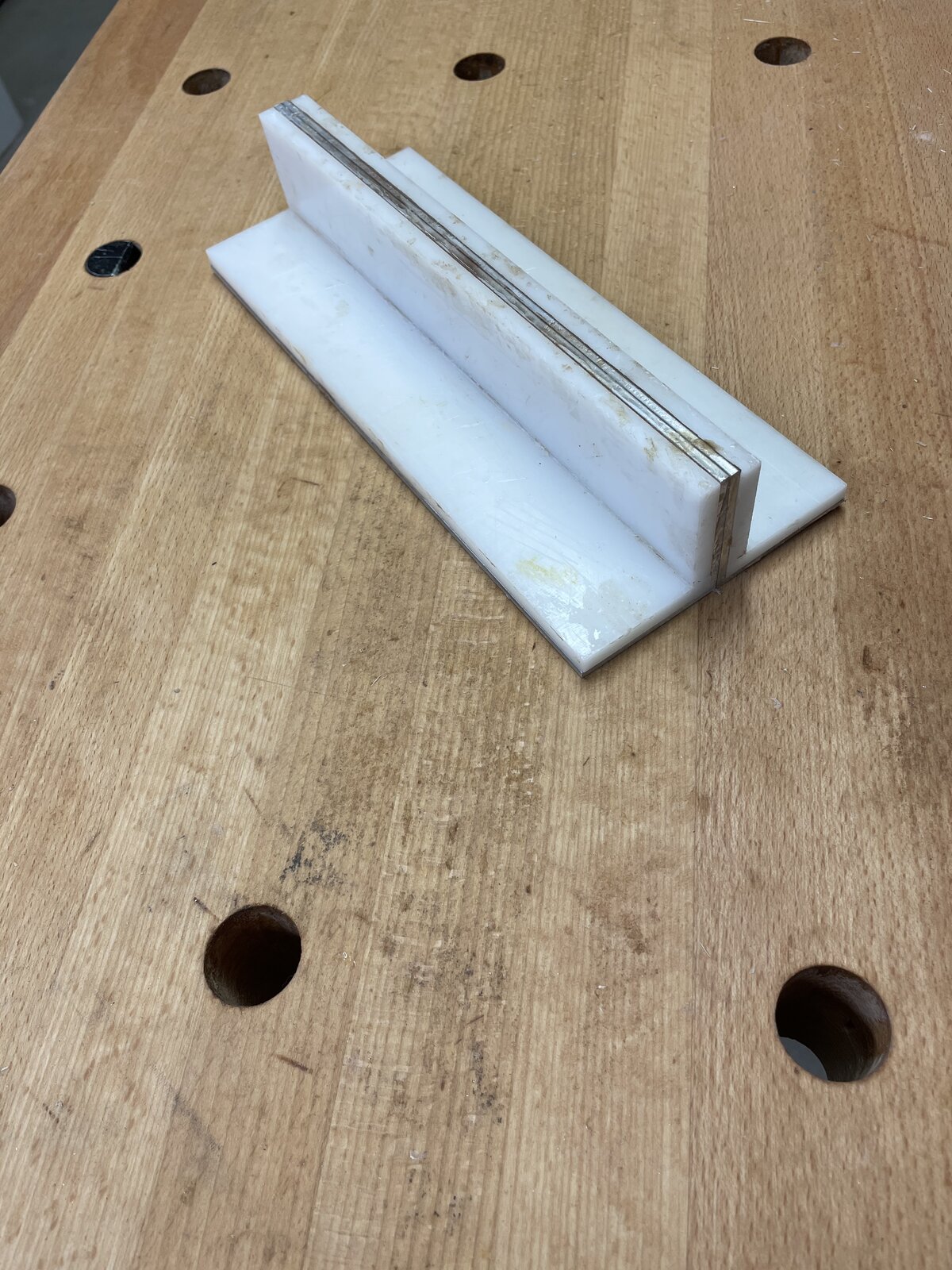

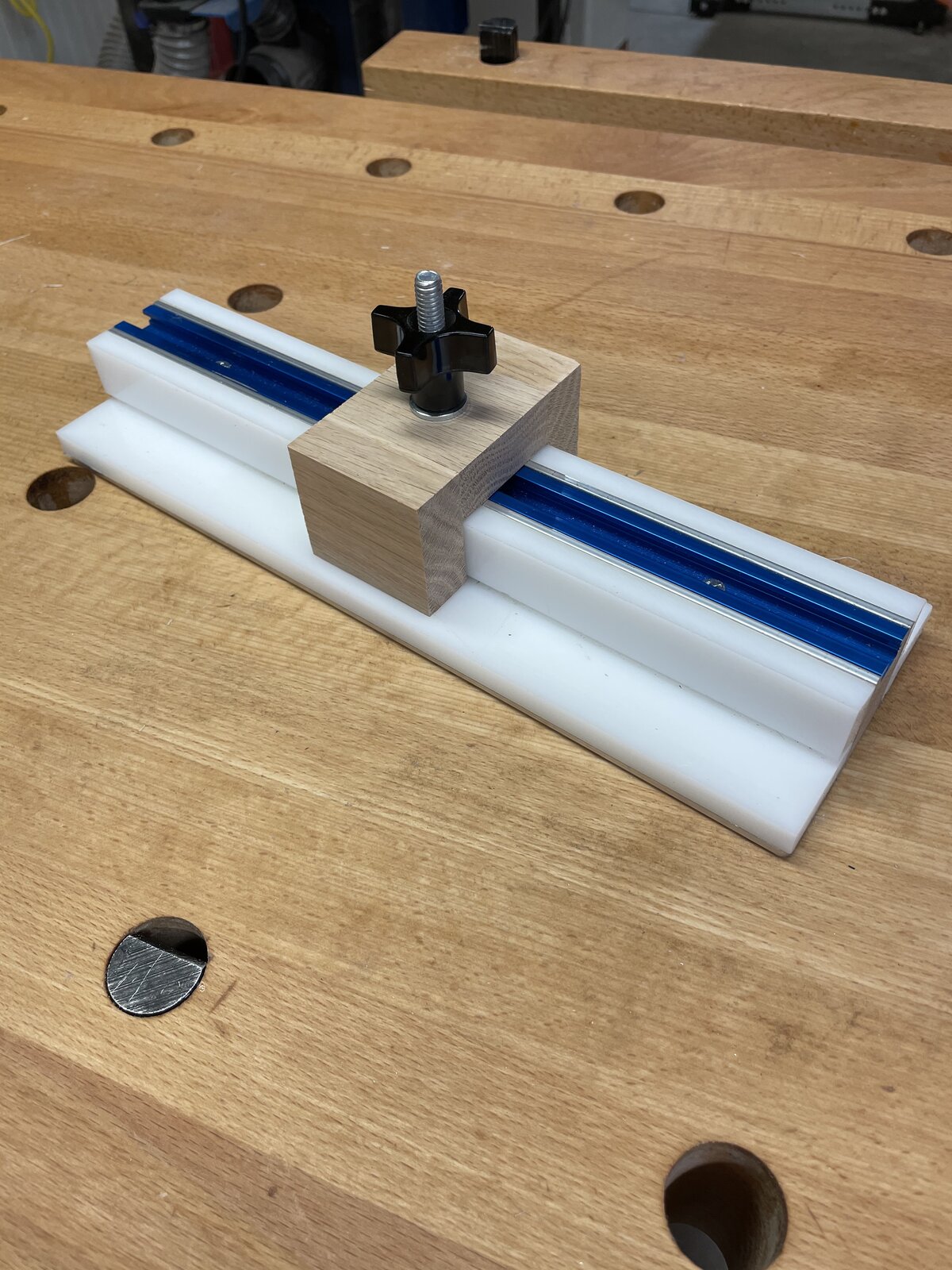

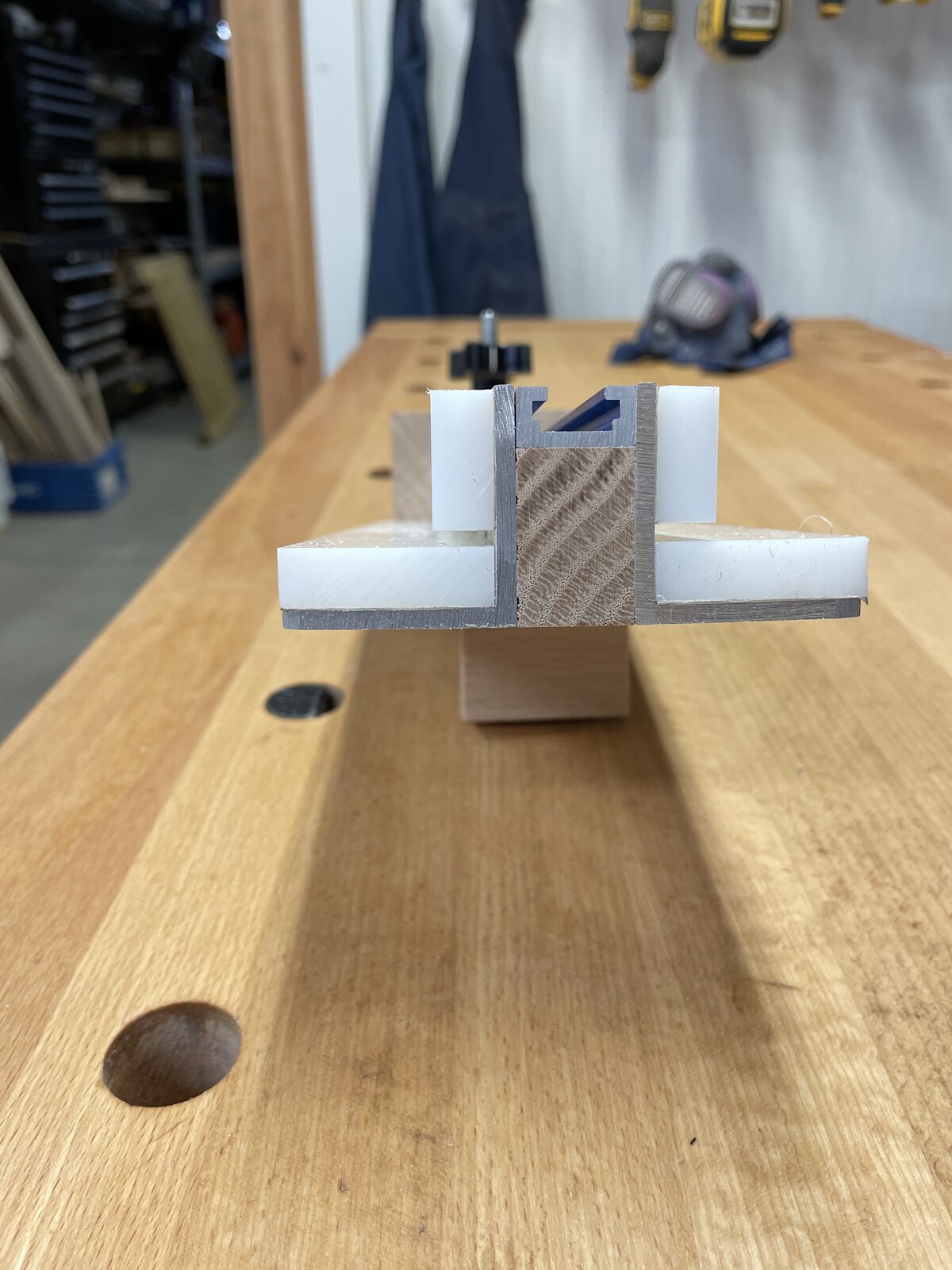

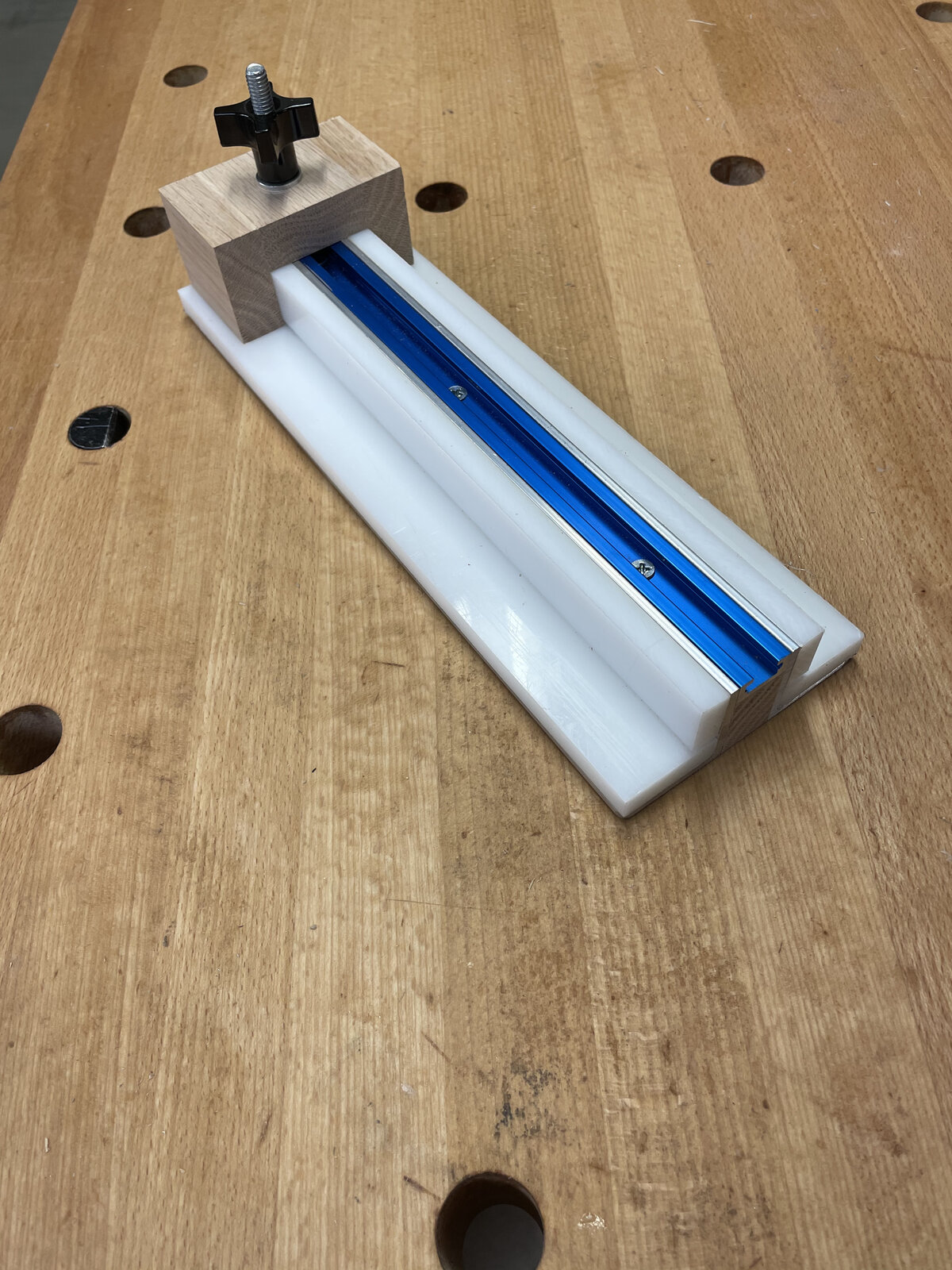

I had made a jig to help with segmented glue ups. It had a couple of issues that I addressed in the new one. First issue I had is when I put the acetel sheet on it, I butted it up tight. When using it, glue would get into the corners and it was difficult to clean it off. Second issue is I was always clamping a stop block on it, my new one has a track on the top so I can put a stop anywhere very easily and also gives me a place to add any feature I dream up. The acetel on the new one also is not butted up tight, there's about a .125 gap and will make it easy to clean the glue off. I'll post a picture of my old one followed by the new one.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New gluing jig

- Thread starter KenB259

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

qquake

Member

Very clever!

Larryreitz

Member

Thanks for posting. I really need to make some jigs and this is a good one to have.

Mal the piece of track is just t track, available any woodworking supply. That one came from Rockler and it was just a leftover piece I had. The acetel is just attached with two way tape, so it can easily come off if need be, for cleaning. The Acetel sheet I bought from Amazon.

Curly

Member

Mal Lee Valley has a variety of T tracks for jigging and fixturing and they are just down the road from you. Busy Bee and KMS probably have some too.

Ken a little too high tech for me. When I did it I just used parchment paper, small clamps, tape or rubber bands.

Ken a little too high tech for me. When I did it I just used parchment paper, small clamps, tape or rubber bands.

TheCraftyCarver

Member

Wow! So nice! The few blanks I've attempted to glue up was by hand, 2 pieces at a time with wood glue & a hand clamp & eyeballing the levelness of the sides .... but you've given me seriously good ideas to contemplate now in how to do it better!

penicillin

Member

- Joined

- Feb 27, 2019

- Messages

- 1,036

Call me dumb or inexperienced, but I am still trying to figure out how it is used. Will you share a photo of how the segment pieces are held in place for a glue-up by this jig?

Pretty much I'll but a piece up to the stop and then C clamp it in place then I can hold the next part in place while the other won't slide all over. I will probably only use this with CA glue. It helps to keep everything square.Call me dumb or inexperienced, but I am still trying to figure out how it is used. Will you share a photo of how the segment pieces are held in place for a glue-up by this jig?

Last edited:

@KenB259

I think that Penicillin and I are pretty much in the same boat ... we're "from Missouri" ..... isn't that "The Show-Me-State" ??? . . . LOL !

Please ... A picture of you actually using this jig ..... the next time you do, or perhaps fabricate a scenario ..... would be very helpful to our understanding.

I realize that you might have all hands in use, with none left over to operate the camera ..... but maybe you can think of a way to "Show Me" ...

I can see how a C-clamp could come into play ..... but wouldn't it sometimes get in the way of what you are trying to do ?

I have to confess to some dumbness or inexperience, also ..... just like Penicillin .....

!!

!!

I think that Penicillin and I are pretty much in the same boat ... we're "from Missouri" ..... isn't that "The Show-Me-State" ??? . . . LOL !

Please ... A picture of you actually using this jig ..... the next time you do, or perhaps fabricate a scenario ..... would be very helpful to our understanding.

I realize that you might have all hands in use, with none left over to operate the camera ..... but maybe you can think of a way to "Show Me" ...

I can see how a C-clamp could come into play ..... but wouldn't it sometimes get in the way of what you are trying to do ?

I have to confess to some dumbness or inexperience, also ..... just like Penicillin .....

Here you go, just two cutoffs that might be glued together. Cocobolo butted up to the stop and held in place by the small clamp. Now the zebra wood piece could have glue applied and held very easily to the cocobolo piece. Nothing slides around and all held square. Hope the picture helps.@KenB259

I think that Penicillin and I are pretty much in the same boat ... we're "from Missouri" ..... isn't that "The Show-Me-State" ??? . . . LOL !

Please ... A picture of you actually using this jig ..... the next time you do, or perhaps fabricate a scenario ..... would be very helpful to our understanding.

I realize that you might have all hands in use, with none left over to operate the camera ..... but maybe you can think of a way to "Show Me" ...

I can see how a C-clamp could come into play ..... but wouldn't it sometimes get in the way of what you are trying to do ?

I have to confess to some dumbness or inexperience, also ..... just like Penicillin .....!!

Attachments

@KenB259 .......... Thanks, Ken .....

OK ..... I get the butt joint application ..... and I can see how you would extend that to angled cuts .

Are there any other applications ? .... say laminating a stack of thin slices like veneer but thicker than the usual veneer ??

Or how about making chevrons ? ..... larger scale than the fine-scale chevrons that Mark James makes in strips from veneers

I am getting interested in trying some segmentation, but of a "random" nature ..... angled cuts + laminated sections + wedge shapes.

But I am not very well-advanced in my thinking of how to construct these. . Just trying to work out the scope of what is possible.

I know that wood128 does some of these, and some are for sale on ExoticBlanks.

I suppose that it might be a case of making custom jigs to suit the particular application, whatever that might be.

Anyway, Ken, I have a better idea now of what you use this particular jig for and how you use it ..... and also the features of your jig .

It is a very useful idea and it might seed thoughts for further development.

Thanks again for going to the trouble of providing the above picture !

BTW ..... what size angle aluminum did you use in that jig ? . . Looks like 1.5" or 2"

OK ..... I get the butt joint application ..... and I can see how you would extend that to angled cuts .

Are there any other applications ? .... say laminating a stack of thin slices like veneer but thicker than the usual veneer ??

Or how about making chevrons ? ..... larger scale than the fine-scale chevrons that Mark James makes in strips from veneers

I am getting interested in trying some segmentation, but of a "random" nature ..... angled cuts + laminated sections + wedge shapes.

But I am not very well-advanced in my thinking of how to construct these. . Just trying to work out the scope of what is possible.

I know that wood128 does some of these, and some are for sale on ExoticBlanks.

I suppose that it might be a case of making custom jigs to suit the particular application, whatever that might be.

Anyway, Ken, I have a better idea now of what you use this particular jig for and how you use it ..... and also the features of your jig .

It is a very useful idea and it might seed thoughts for further development.

Thanks again for going to the trouble of providing the above picture !

BTW ..... what size angle aluminum did you use in that jig ? . . Looks like 1.5" or 2"

I haven't used the new one yet, but the old one I used for laminating strips as well and used those for chevrons. I think the aluminum angle is 1 1/2.@KenB259 .......... Thanks, Ken .....

OK ..... I get the butt joint application ..... and I can see how you would extend that to angled cuts .

Are there any other applications ? .... say laminating a stack of thin slices like veneer but thicker than the usual veneer ??

Or how about making chevrons ? ..... larger scale than the fine-scale chevrons that Mark James makes in strips from veneers

I am getting interested in trying some segmentation, but of a "random" nature ..... angled cuts + laminated sections + wedge shapes.

But I am not very well-advanced in my thinking of how to construct these. . Just trying to work out the scope of what is possible.

I know that wood128 does some of these, and some are for sale on ExoticBlanks.

I suppose that it might be a case of making custom jigs to suit the particular application, whatever that might be.

Anyway, Ken, I have a better idea now of what you use this particular jig for and how you use it ..... and also the features of your jig .

It is a very useful idea and it might seed thoughts for further development.

Thanks again for going to the trouble of providing the above picture !

BTW ..... what size angle aluminum did you use in that jig ? . . Looks like 1.5" or 2"