floatslow

Member

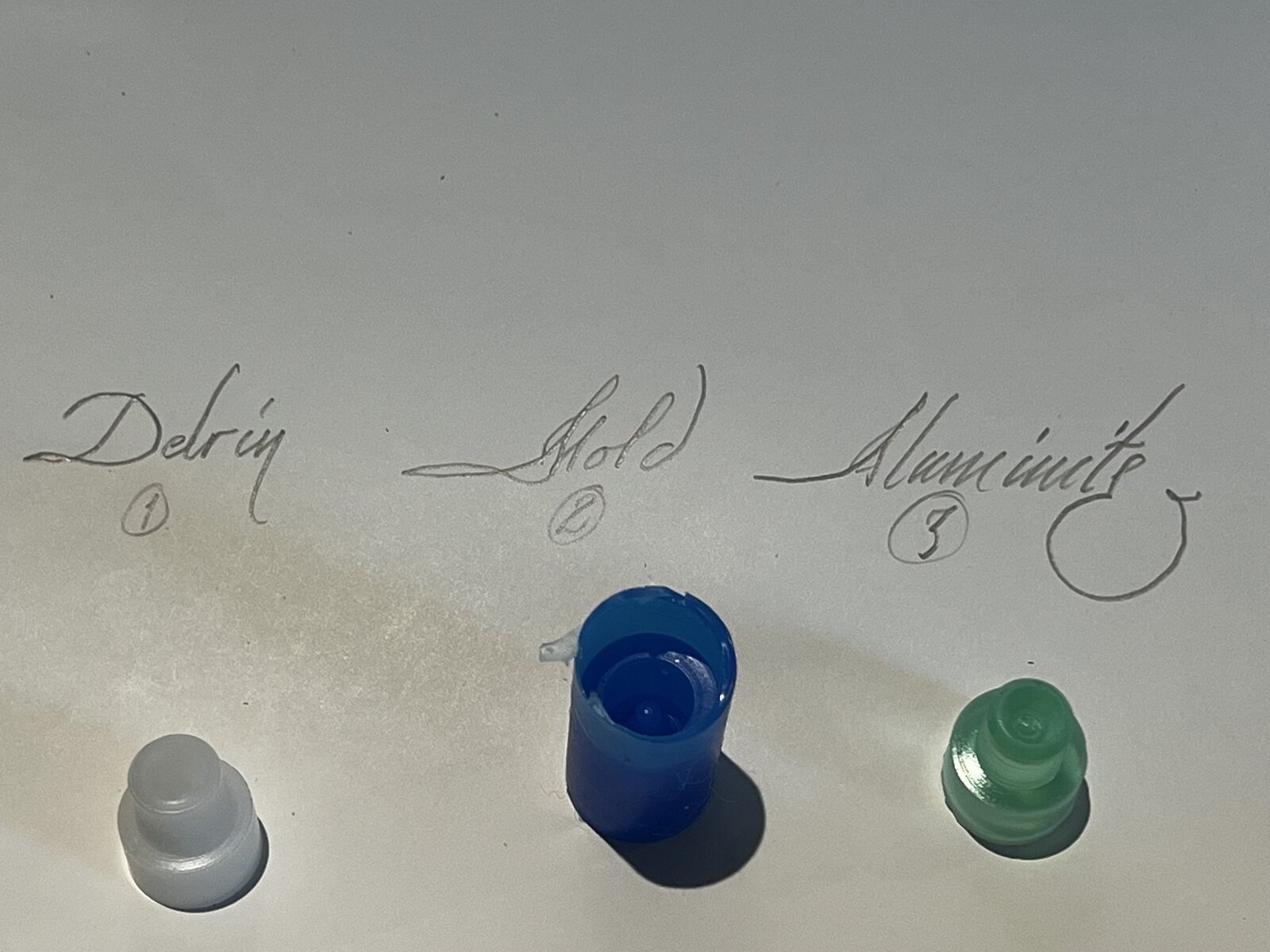

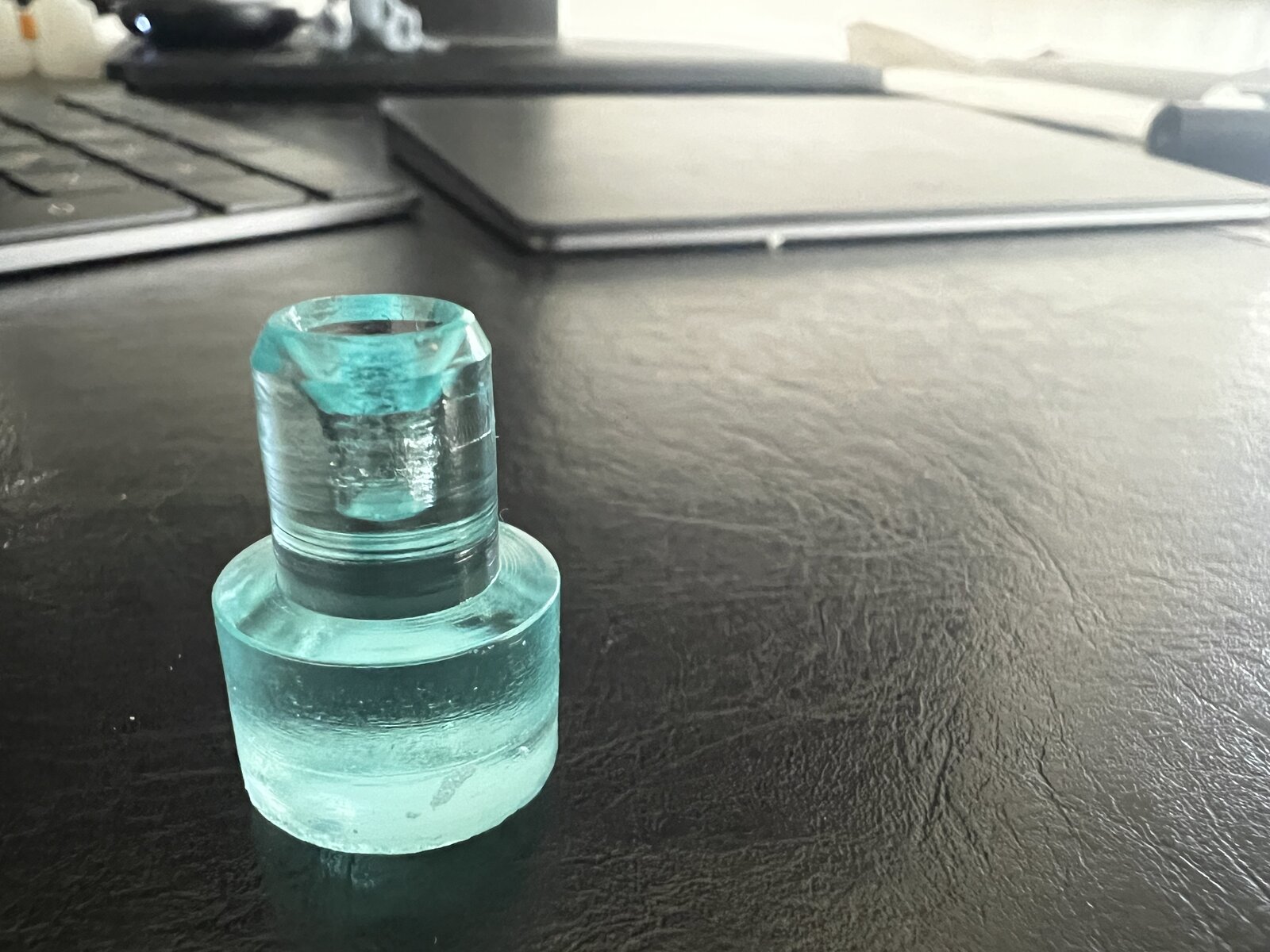

I have been playing around with creating molds so that my Alluminite pours are closer to final shape for my section, finials, and windows. The intent being to reduce wasted material and minimize time to turn to the desired shape. I initially tried additively manufacturing with an Elegoo Mars3 (MSLA) {stereo lithography} but the resin did not react well with the platinum based silicone mold material. I have not tried sealing or using organic resin. I subsequently switched to turning delrin rod to the desired shape. I have had most luck casting in a PVC pipe section, but would like to attempt a two part mold next.

I would love to hear of anyone else's experience doing such an activity. I have done a little research on the forums, but wouldn't mind to be pointed to more info and correct terminology.

Thanks - Mark

I would love to hear of anyone else's experience doing such an activity. I have done a little research on the forums, but wouldn't mind to be pointed to more info and correct terminology.

Thanks - Mark