Painfullyslow

Member

Thanks once again to the mountain of information found on this site, I am happy with my first attempt at casting blanks. I detailed the process below but if this bores you (I wouldn't blame you!) then skip to the end for pictures.

To make this I used:

I measured the volume of the mold by filling with water and then pouring into a graduated container. Just over 450ml. Since the LD resin is a 2:1 formula that meant some easy math of 300ml resin with 150ml hardener. I prefer to measure by weight so I zero'd out my scale with my mixing container on it and added 300ml of resin, then recorded the weight. Divide that by half, zero the scale again, and then add the hardener.

Thoroughly mixing slowly to reduce bubbles I then separated the resin into three 150ml cups and stirred in my mica powders, one color per container.

It was at this point where I realized that I could not find my laser thermometer so I quickly searched the web and discovered that on average the LD resin got to about 120 degrees around the 45-50 min mark in most cases. Far less accurate than I would have liked but I had to make do.

so I quickly searched the web and discovered that on average the LD resin got to about 120 degrees around the 45-50 min mark in most cases. Far less accurate than I would have liked but I had to make do.

I checked it about every 15 min, stirring again to ensure no mica settled but I needn't have worried. Everything stayed in suspension quite nicely.

At 45 min the cup felt warm to the touch but I felt it was not ready so I waited another 10 minutes. I assume this was due to the relatively small volume in each cup. At 55 min the cup was noticeably warmer and the resin had just started to thicken a bit so this was when I decided to pour.

I just randomly poured the colors into the mold, varying motion and how aggressively I poured. This left a pleasingly random pattern but to be sure I used a wooden skewer to make some quick swirls in the combined colors.

After that, it was off to the shelf to cure for 24 hours. Demolding was a piece of cake, it practically fell out of the mold.

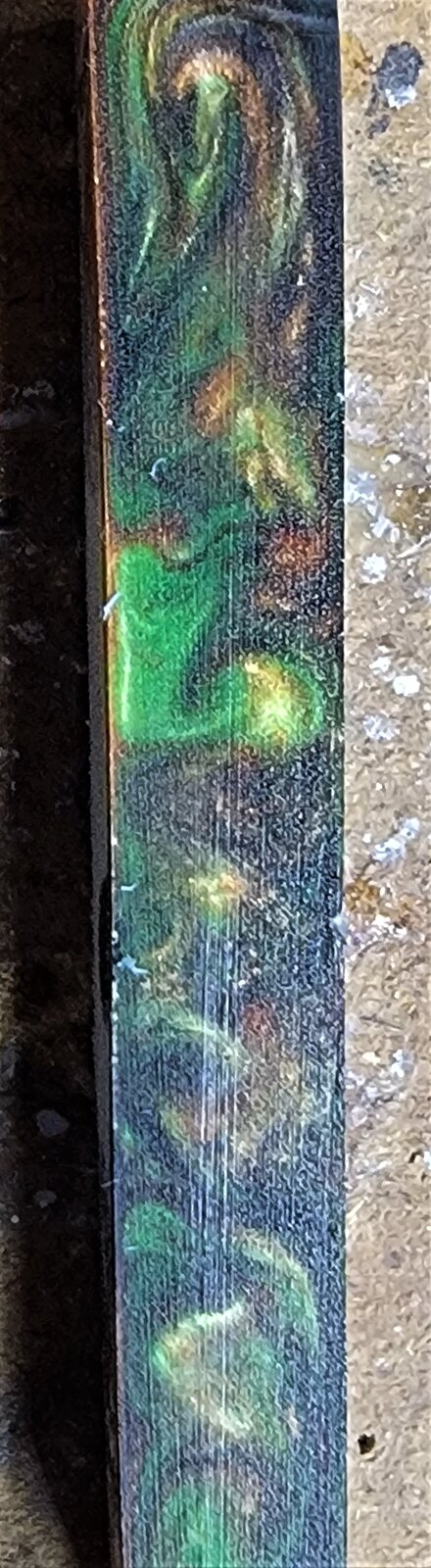

These are the pieces after cutting into 0.75"x6" blanks. This is the cut edge so not shiny but I felt it gave the best look at the interior of the blank.

The pictures are pretty grainy so I will have to see after turning how it turns out but so far it looks promising!

Sorry for the length, I just wanted to post my process here as a means of recording my method.

To make this I used:

- 5.25"x6"x0.75" silicone mold sprayed with mold release

- Liquid Diamonds casting resin

- Graphite, Copper, and Parakeet Green mica powder

- paper to protect my work surfaces, nitrile gloves, and even though this resin states no VOC I wore a respirator out of habit when working with epoxy

- 8 oz (~235ml) graduated mixing cups and wooden tongue depressor sized mixing sticks

I measured the volume of the mold by filling with water and then pouring into a graduated container. Just over 450ml. Since the LD resin is a 2:1 formula that meant some easy math of 300ml resin with 150ml hardener. I prefer to measure by weight so I zero'd out my scale with my mixing container on it and added 300ml of resin, then recorded the weight. Divide that by half, zero the scale again, and then add the hardener.

Thoroughly mixing slowly to reduce bubbles I then separated the resin into three 150ml cups and stirred in my mica powders, one color per container.

It was at this point where I realized that I could not find my laser thermometer

I checked it about every 15 min, stirring again to ensure no mica settled but I needn't have worried. Everything stayed in suspension quite nicely.

At 45 min the cup felt warm to the touch but I felt it was not ready so I waited another 10 minutes. I assume this was due to the relatively small volume in each cup. At 55 min the cup was noticeably warmer and the resin had just started to thicken a bit so this was when I decided to pour.

I just randomly poured the colors into the mold, varying motion and how aggressively I poured. This left a pleasingly random pattern but to be sure I used a wooden skewer to make some quick swirls in the combined colors.

After that, it was off to the shelf to cure for 24 hours. Demolding was a piece of cake, it practically fell out of the mold.

These are the pieces after cutting into 0.75"x6" blanks. This is the cut edge so not shiny but I felt it gave the best look at the interior of the blank.

The pictures are pretty grainy so I will have to see after turning how it turns out but so far it looks promising!

Sorry for the length, I just wanted to post my process here as a means of recording my method.