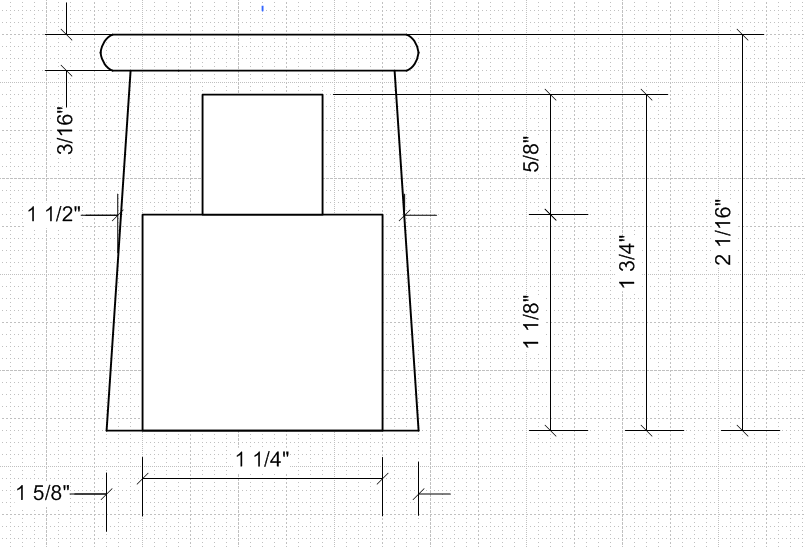

I made some of these a few weeks ago. The sketch illustrates the dimensions. Key points:

1. The stopper has to fit over the neck of the bottle. I measured a few wine bottles, and found that a cavity diameter of 1.25" should cover just about everything.

2. There are two factors that govern the overall height of the stopper. One is how much 'meat' is required in the stopper to hold the 'works' in place, and of course, that depends on the kind of 'works' you plan to use. I like the Ruth Niles stainless steel units, but they are rather expensive, and since I tend to give away stoppers, I don't want to incur that much cost. I keep a few in the shop, but most of the stoppers I make use the much less costly PSI silicone sleeve + dowel design. The dowel that come with these is tapered - a 1/2" section that fits into the silicone sleeve, and a 3/8" section that is meant to be glued into the stopper turning. That 3/8" section is 3/4" long, but my experience is that it is possible to shorten the length without affecting the functionality of the stopper. So I take at least 1/8" off, and sometimes as much as 1/4", leaving 1/2-5/8" to be glued in. However, the thickness of the wood above the cavity must be sufficient that the hole that is drilled to receive that dowel doesn't penetrate through the top of the stopper turning.

3. The other factor is whether the 'works' portion of the stopper protrudes below the bottom of the stopper turning. I prefer that the 'works' remain completely hidden so that I can place a stopper on its bottom (so that it won't roll away) on a table next to the bottle and have a small gap between the table top and the bottom of the 'works'. With the PSI silicone + dowel 'works', the silicone sleeve is about 1 1/16" long, so I make the cavity 1 1/8" deep.

4. Taken together, these factors dictate that my designs tend to be 2 1/16" tall, which means that the stopper occupies about 15/16" of headspace above the actual top of a wine bottle. It's possible to make them slightly shorter, but not by much.

5. I also take a different approach with regard to mounting the stopper on the lathe for turning. Most people us a stopper mandrel that has a 3/8"x16tpi stud to hold the blank in place - and you are expected to drill a 5/16" hole and then thread it with a 3/8"x16tpi tap. The problem with that is that stopper blanks tend to be in spindle orientation, which means that the grain in the timber runs from (finished) bottom to top: that means that the hole must be drilled and tapped in end grain. End grain wood doesn't tap very well, and the threads can easily strip out. while turning. My solution is to make a threaded insert by drilling an tapping a 3/8"x16tpi hole in face grain timber, mount it on a mandrel and turn it down to a 5/8" diameter plug that I then glue into a 5/8" diameter hole in the turning blank. So that means that there are two constraints in shaping the outside of the turning - first, I want to leave about 1/8" of material between the inside corner of the cavity, and the outside of the turning. Second, while the wall thickness between the outside of the turning and that glued-in plug isn't critical for strength, I want to leave enough material that it isn't possible to see the glue line between the outer shell and the plug. (Incidentally, the 3/8" dowel won't fit into a hole with a 3/8"x16tpi thread - so after the stopper has been completed, I ream out the hole using a 23/64" drill bit that removes enough of the threading that the dowel can be glued in.)

6. I've thought about using the Woodcraft 'works' that consist of only the silicon sleeve - you have to make your own tapered dowel, In that instance, I might make the portion of the dowel that is to be glued into the turning slightly more narrow - say 23/64" - so that I can glue it in without having to ream out the mounting hole.

7. Finally, while it would be OK for the turning to be a simple cylinder, I think it works better to have some shape so that it's easier to grip when you remove the stopper from a wine bottle. Aesthetically, however, I think they tend to look better if the outside diameter is relatively narrow - fat just doesn't look good given the relatively short height of these stoppers. I've made several where the blank is a glue-up of sorts - most often where that 'top hat' portion is a contrasting material, or where there is a constrasting insert glued into a recess in the top. Applying texture on the top also works. Giving the top a slight dome shape is nice, but that tends to consume more headspace above the top of the wine bottle when it goes in the fridge.