Whiskeyjack78

Member

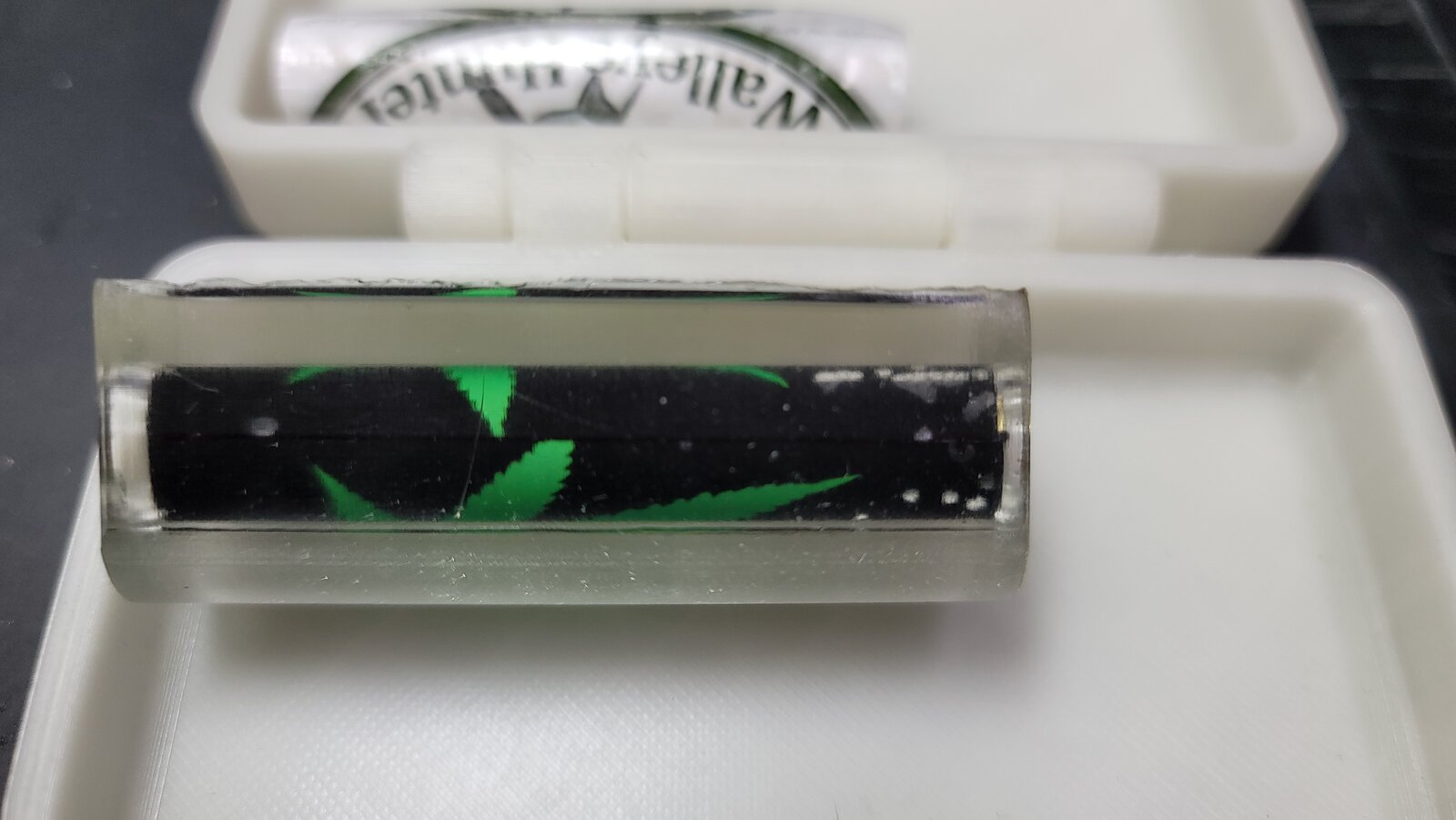

Hi all, My name is Marc. I'm from Alberta, Canada. I apologize for asking for help in my first ever Pen Turners post but I need some expertise help.

I'm attempting to make some Label castings and have run into a significant problem. I can't seem to get the resin to stick to the label correctly.

Here's a list of all my equipment and materials I'm using:

Alumilite Clear Slow & Alumilite Clear

PTownSubbie Tube in Blue Silicone Mold

Sierra Size Pen Tubes

Premium Printable Vinyl Waterproof Paper for Inkjets

California Pressure Pot 2.5 @ 60PSI

Stoner Urethan Mold Release

This issue doesn't come up until a hour after I take it out of the pot and demold.

If anyone has any suggestions i would greatly appreciate any help.

Thanks;

Marc

I'm attempting to make some Label castings and have run into a significant problem. I can't seem to get the resin to stick to the label correctly.

Here's a list of all my equipment and materials I'm using:

Alumilite Clear Slow & Alumilite Clear

PTownSubbie Tube in Blue Silicone Mold

Sierra Size Pen Tubes

Premium Printable Vinyl Waterproof Paper for Inkjets

California Pressure Pot 2.5 @ 60PSI

Stoner Urethan Mold Release

- I install the sticker on tube

- Warm up the mold in the oven @ 150F for 5-10 minutes.

- Pour equal parts A&B by weight and mix.

- Install tubes into mold

- Pour resin in mold

- Put in pressure pot (Have done for 2hrs and 12hrs)

This issue doesn't come up until a hour after I take it out of the pot and demold.

If anyone has any suggestions i would greatly appreciate any help.

Thanks;

Marc