I feel like my kitless journey is progressing. My fit and finish have improved since I started making my metal bands. I switched to Caswell buffing wheels and compounds this week, which seems to be a significant improvement over my other compounds. I started using a rotary tool with a very soft buffing wheel to polish my threads with magic juice 1 and 2, and these are my best-looking threads yet. I forgot to polish my section threads in the last picture so that you can see the improvement made by my new polishing method.

I am happy with my progress and plan to become a little more adventurous with design. I want to start experimenting with a step-less design next. I feel like I am trying to cram too many elements into a pen as I experiment with design aspects, so I plan on simplifying the accents in the future.

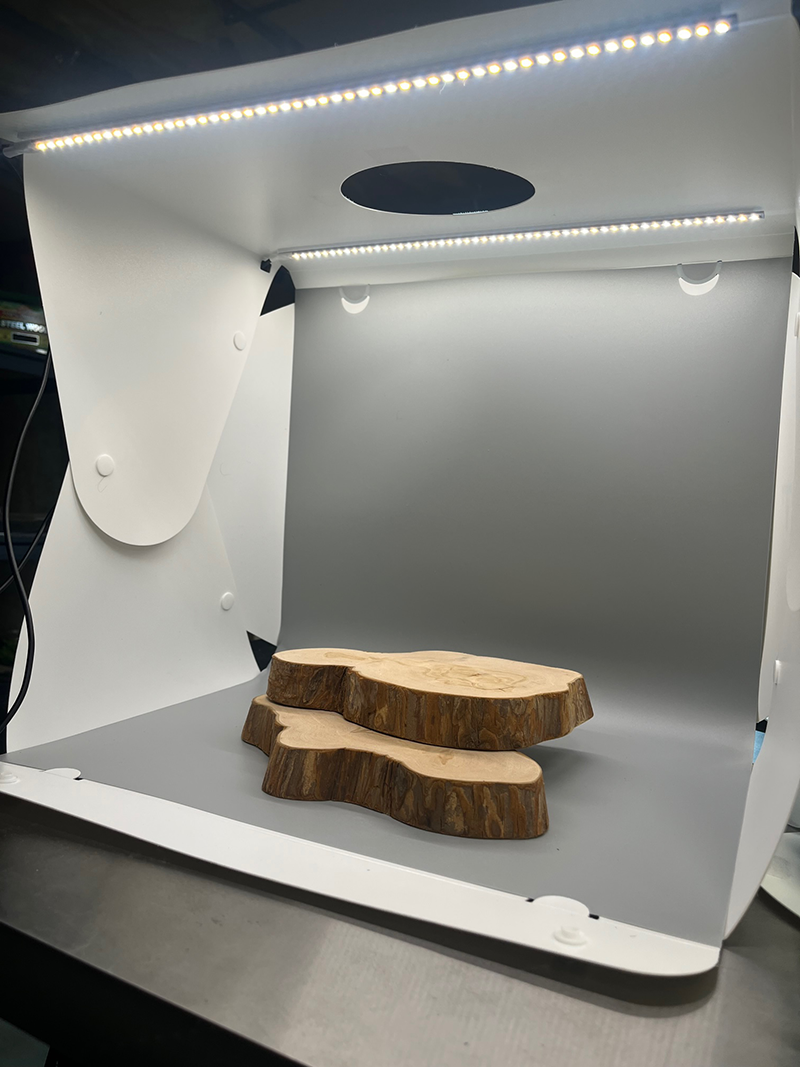

I am also trying to improve my photography. I have a little lightbox and use my iPhone. I have a picture of my lightbox below and hope to get some advice for improving my photo setup so that my pens don't look like a disco ball hanging over them in pictures. I have tried covering the lights with parchment paper, but I still get the disco ball wavy effect.

I appreciate all advice and criticism to help me improve. Thank you!

Convertible Pen (dual section for rollerball or fountain pen)

M13 x .8 threads

Diamondcast "Oil Slick"

Black accents with Black Diamond Mica

Ebonite Sections

Jowo #6

Beaufort Clip

Additional section with a Beaufort Rollerball nib

Here is my lightbox setup that I am looking for advice with:

Same pen in the lightbox. Notice how it makes the finish look uneven. Any suggestions on making it look more even like the outdoor pictures above but maintaining the color depth I get in the lightbox?

I am happy with my progress and plan to become a little more adventurous with design. I want to start experimenting with a step-less design next. I feel like I am trying to cram too many elements into a pen as I experiment with design aspects, so I plan on simplifying the accents in the future.

I am also trying to improve my photography. I have a little lightbox and use my iPhone. I have a picture of my lightbox below and hope to get some advice for improving my photo setup so that my pens don't look like a disco ball hanging over them in pictures. I have tried covering the lights with parchment paper, but I still get the disco ball wavy effect.

I appreciate all advice and criticism to help me improve. Thank you!

Convertible Pen (dual section for rollerball or fountain pen)

M13 x .8 threads

Diamondcast "Oil Slick"

Black accents with Black Diamond Mica

Ebonite Sections

Jowo #6

Beaufort Clip

Additional section with a Beaufort Rollerball nib

Here is my lightbox setup that I am looking for advice with:

Same pen in the lightbox. Notice how it makes the finish look uneven. Any suggestions on making it look more even like the outdoor pictures above but maintaining the color depth I get in the lightbox?