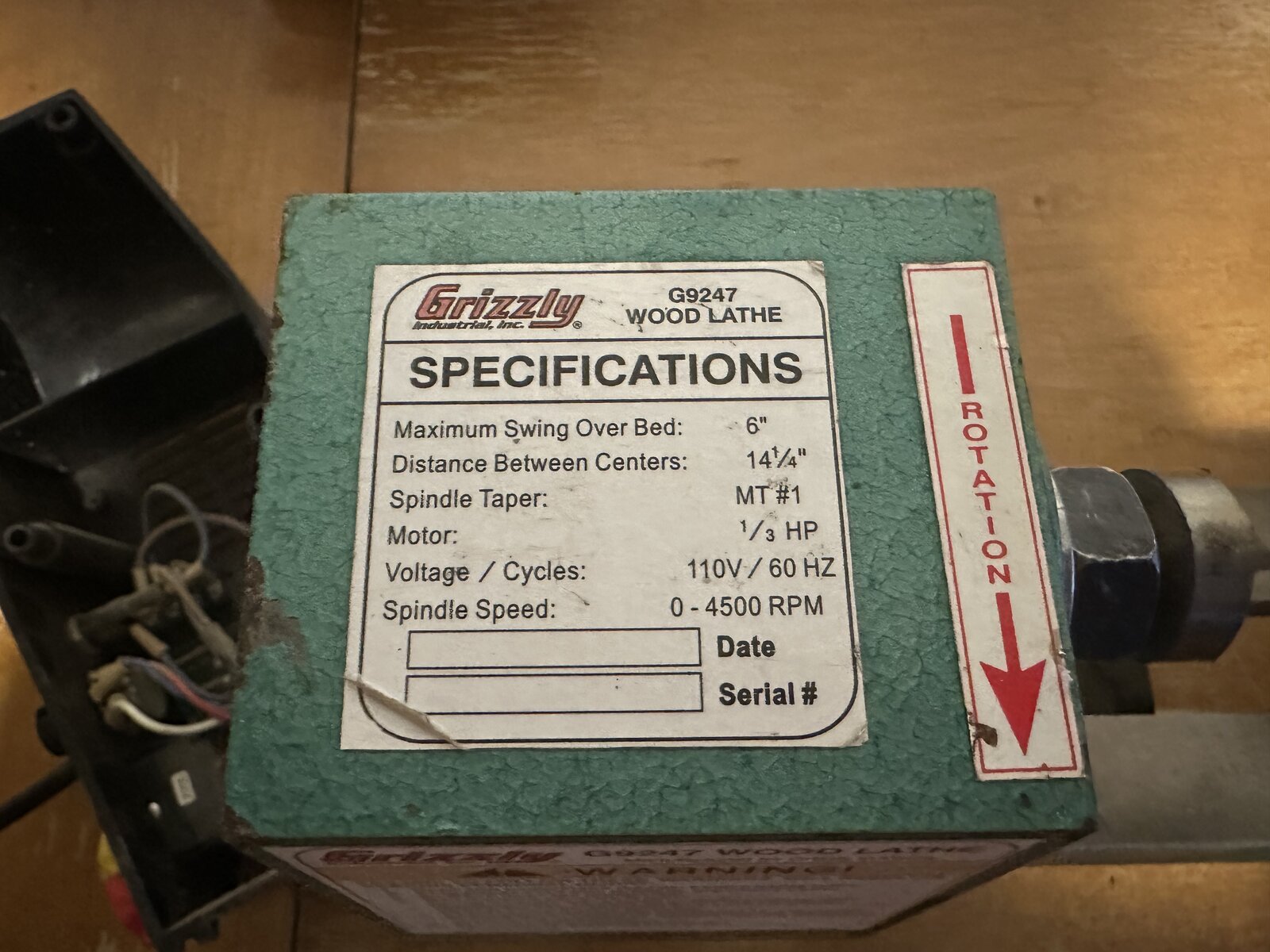

Hey guys. I'm not really a wood turner, yet. But while looking for a metal lathe I ran across this little Grizzly G4297 for $10. The guy said it just needed a belt. The cover was hanging off of it. It was close so I went after it.

I got there and he said he bought new gears, pulled the cover and seen it needed a belt. He didn't want to mess with it anymore. Well it does not look like new gears to me. And there's no screws for the cover. Hmmmm. But for $10 I bought it,,,lol.

Like I said. I'm not a wood turner but I'm interested if I could get this going cheap enough, assuming it's worth fixing? I'd have to buy just a belt for $20. Or belt and gears for $40. Then I would need tools and everything else to get started.

Is this little guy worth the effort?

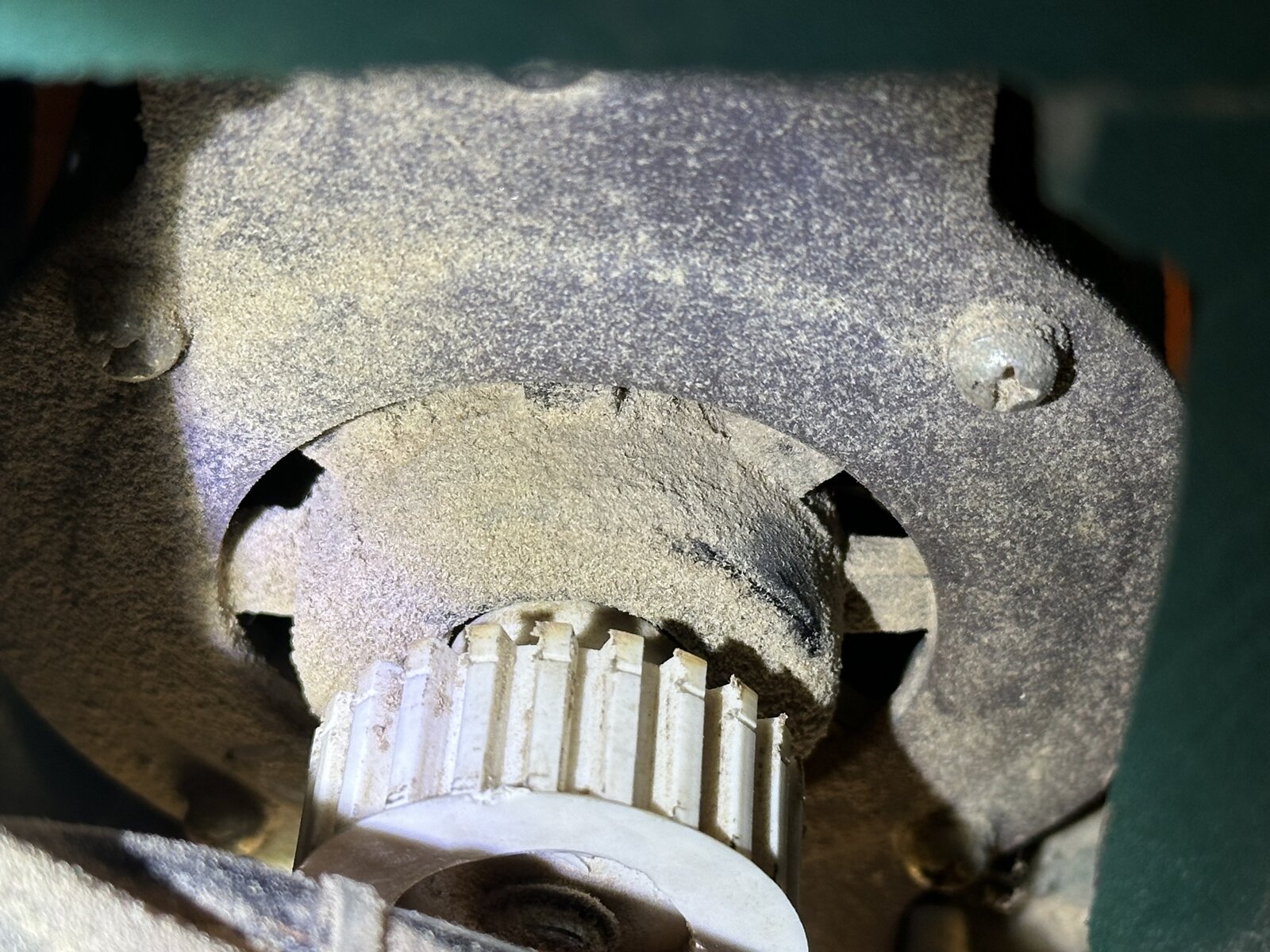

I've read that these eat belts. Do these gears look ok? The motor gear looks like it could be a little damaged? I see a groove in it.

Thanks for any input.

I got there and he said he bought new gears, pulled the cover and seen it needed a belt. He didn't want to mess with it anymore. Well it does not look like new gears to me. And there's no screws for the cover. Hmmmm. But for $10 I bought it,,,lol.

Like I said. I'm not a wood turner but I'm interested if I could get this going cheap enough, assuming it's worth fixing? I'd have to buy just a belt for $20. Or belt and gears for $40. Then I would need tools and everything else to get started.

Is this little guy worth the effort?

I've read that these eat belts. Do these gears look ok? The motor gear looks like it could be a little damaged? I see a groove in it.

Thanks for any input.