MDWine

Member

I set up my HF pot this weekend.

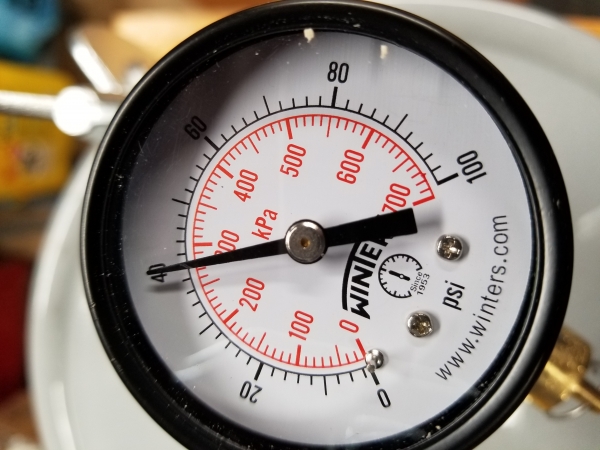

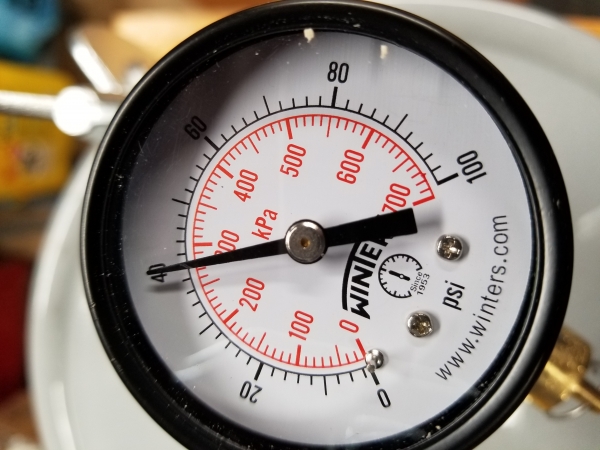

I got all the fixtures attached, and pumped it up to 40 lbs.

(you didn't tell me about the crackling noises it would make, it freaked me out a bit!)

First pump I got a blast of air out from under the lid. I lubed the gasket lightly with some white lithium grease and pumped it up again.

I stopped at 40 pounds, and it held stead for 3 hours... so I declared victory.

Hopefully, I can slip a piece or two into it and see how I do. I'll make a tray for the inside at some point, but am anxious to give this thing a trial run.

Thanks to all for the chatter and all of the insight this forum provides.

I got all the fixtures attached, and pumped it up to 40 lbs.

(you didn't tell me about the crackling noises it would make, it freaked me out a bit!)

First pump I got a blast of air out from under the lid. I lubed the gasket lightly with some white lithium grease and pumped it up again.

I stopped at 40 pounds, and it held stead for 3 hours... so I declared victory.

Hopefully, I can slip a piece or two into it and see how I do. I'll make a tray for the inside at some point, but am anxious to give this thing a trial run.

Thanks to all for the chatter and all of the insight this forum provides.