EdM

Member

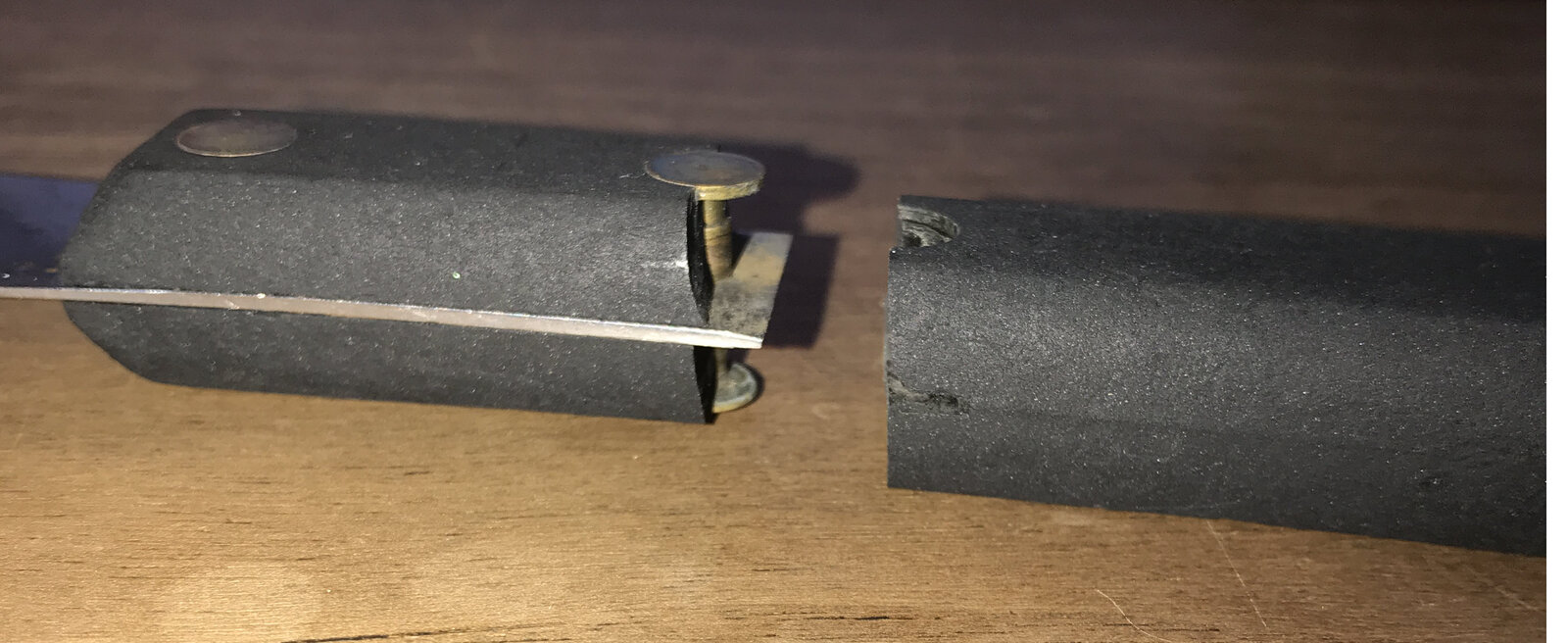

A friend recently asked me to repair this icing spreader, which is probably 50 years old, and belonged to her mother.

The handle appears to be Bakelite, but may be some type of high density plastic as well.

Once properly glued, it will make a very clean repair, but I don't know whether I should use thick GluBoost CA or 5 minute epoxy.

Any suggestions on this would be greatly appreciated .

Thanks!

Ed

The handle appears to be Bakelite, but may be some type of high density plastic as well.

Once properly glued, it will make a very clean repair, but I don't know whether I should use thick GluBoost CA or 5 minute epoxy.

Any suggestions on this would be greatly appreciated .

Thanks!

Ed