The whole process that I will be posting here bit by bit comes from those who have already performed the mods on Phil Thiens website. If you are not sure who that is, look him up. The forum is another treasure chest.

The air is reported to be slight, no more 200 CPM range as I recall. The suction increase in static pressure I believe is about 50%.

In all reality, the original HF blades are more "backwards" than those on the Rikon impeller. The HF is scooping the air, trying to move more air with a small impeller resulting in less efficiency and lower static pressure. The reverse incline is actually the more efficient design.

Reports indicate the motors holding up fine on a properly wired circuit. Some undersized/overloaded circuits report tripping on start up. I have had no issues.

Notice the impeller is slightly offset in the housing. It is this offset that helps throw the dust into the bag, not the shape of the blades.

Good observation, Les. From Phil's website, they not only look the same but all measurements are identical except for the impeller and bag. The HF is forward incline, achieving CFM at lower static pressure with a smaller diameter i.e. cheaper impeller which can more easily overload. I would guess they come from the same factory, too.

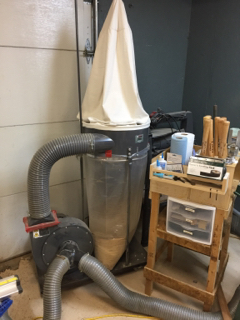

Biggest observation is the "swirl" in the bag, wish I had videoed before and after. Was a decent effect, say the fines were swirling around visually about 3 times. With new impeller the same effect is tight, maybe 9 or 10 times. Not very scientific but noticeable. Next will add a Thien baffle, as that will drop most of the stuff out ahead of the bag. Will also upgrade bag to a wynn pleated filter.

The impeller is part #22 for a Rikon DC60-200. There is a backlog, mine took over 2 months to come in. Price was $100 plus $20 shipping.

From my spreadsheet I will end up with a modified HF with Thien baffle, .5 micron filter for about $500-$600 vs a Rikon or Jet with Thien baffle and .5 micron pleated filter for about $1100.

I have experience with fan/blower design and application from both steel and mining as well as other heavy industry and a stint in large motor design years ago.

Applying what others have learned. Make sure you do not jump in and do mods you are not comfortable with or understand the associated risks, gang. Not worth it.

Sent from my iPhone using

Penturners.org mobile app