jmbaker79

Member

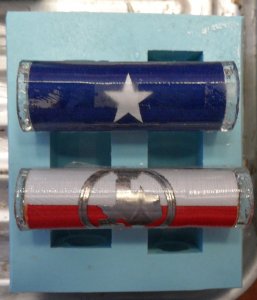

Alright so we potentially have our first actual order, finding out today, for 100 sierras. These are for a super well known coffee company, that apparently IAP members dont seem to be a fan of, except for myself....We are using "bag stamps" they are basically giant stamp stickers. So I wrapped them around the tubes, and ran a little thin ca over the seam as after a day or two they started to peel up at the seem. The ca fixed this no problem. Used a pencil sharpener to make plugs, and glued them in the ends with ca. Cast, not under pressure, with PR, no bubbles, no problem. The real issue here is that knocking out the plugs has cracked a few of the test runs, just right at the edge, figure i could mill it off. Going to find out how much I can shorten these tubes as the stamps are a little short. When milling though, the little heat generated inside the tubes seems to dissolve the adhesive on the back of the stamps, and the tubes either start spinning inside the blank, or stay on the mill when the blank comes off. This is a super headache, as these are going to be due in about two weeks for a conference. I believe I have this fixed as i just put the mill into a drill chuck in the tailstock, and used a little disc sanding jig i made in the head stock, seems to square them up pretty good, yet to assemble one though and find out. These seem similar to label casting, so is this common? This has also happened using double sided tape in the past. ID 10 T Error possibly? Didnt seal these either after wrapping the tubes so thinking about throwing each on the lathe and hitting it with a coat or two of CA before casting...think it will help seal the ends to the tube? Any help or advice is appreciated greatly!