Kylemadeit

Member

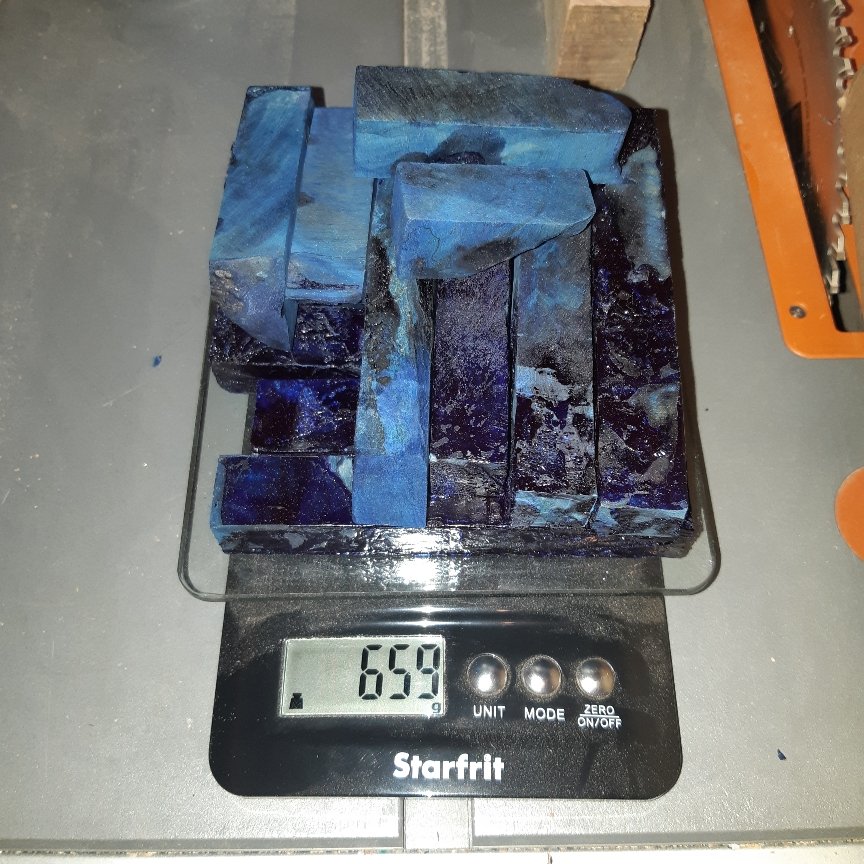

My 2nd and 3rd go at stabilization! I am very very happy. I had great material to work with. Some nice slabs of punky spalted maple burl. I didn't touch the really crazy stuff yet [emoji6]. I used cactus juice and cactus juice dye. The 3rd (blue) was the best yet I think. I had a bit of a creep up in temp during curing on the 2nd but was right there to deal with it and I don't think i lost much. Here are some pictures of my results. Dried weight vs. Cured. Finally, the first couple pens from the batch, they turn and finish like a dream  looking forward to using the blue

looking forward to using the blue

Sent from my SM-A530W using Tapatalk

Sent from my SM-A530W using Tapatalk