Bob in SF

Member

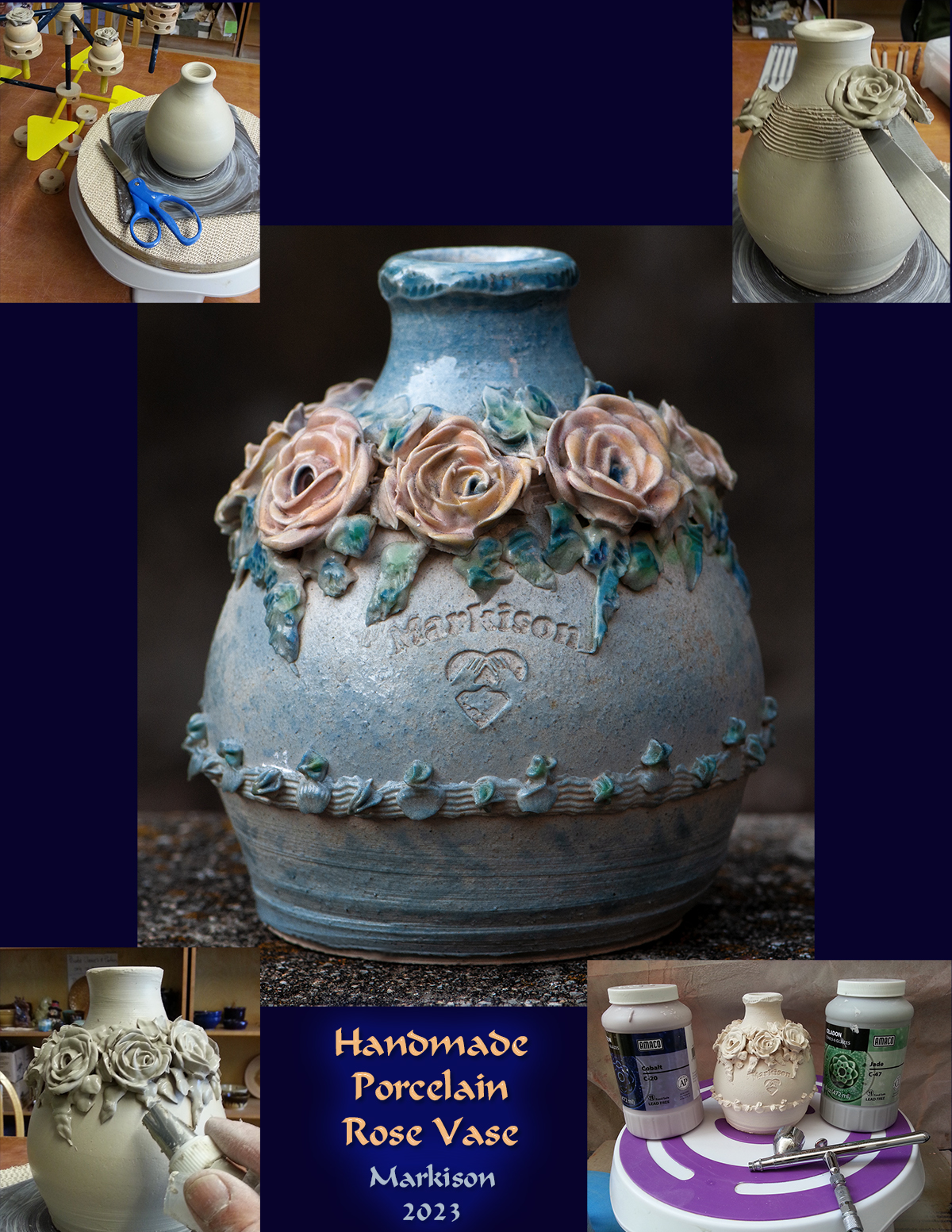

This was a pleasant commission for a rose fancier.

Steps:

Make porcelain throwing and piping clay from scratch, using a combination of recipes published in "Ceramics Monthly" magazine dating back to the 1960's (clay bodies containing kaolin, silica, feldspar and other ingredients).

Throw the vase body on the potters wheel.

Circumferentially roughen the areas of the vase that will receive the blossoms and leaves.

Thin some of the porcelain down to butter cream frosting texture with an immersion blender, then pipe the rose blossoms onto an improvised array of rotating platforms made from a K'nex set (think Tinker Toys 2.0).

Carefully lift the roses off of the platforms with scissors, and nestle them onto the vase.

Pipe the leaves around the roses, pipe the lower decoration, and stamp the makers mark onto the vase.

Let dry for 2 weeks in a warm room, then bisque fire.

Hand brush and airbrush the colored and clear glazes onto the roses-clad vase, then final fire in the kiln at cone 6.

Warm regards to all makers.

Fondly - Bob

(PS: I'll get back to pen turning soon - in plenty of time for Christmas).

Steps:

Make porcelain throwing and piping clay from scratch, using a combination of recipes published in "Ceramics Monthly" magazine dating back to the 1960's (clay bodies containing kaolin, silica, feldspar and other ingredients).

Throw the vase body on the potters wheel.

Circumferentially roughen the areas of the vase that will receive the blossoms and leaves.

Thin some of the porcelain down to butter cream frosting texture with an immersion blender, then pipe the rose blossoms onto an improvised array of rotating platforms made from a K'nex set (think Tinker Toys 2.0).

Carefully lift the roses off of the platforms with scissors, and nestle them onto the vase.

Pipe the leaves around the roses, pipe the lower decoration, and stamp the makers mark onto the vase.

Let dry for 2 weeks in a warm room, then bisque fire.

Hand brush and airbrush the colored and clear glazes onto the roses-clad vase, then final fire in the kiln at cone 6.

Warm regards to all makers.

Fondly - Bob

(PS: I'll get back to pen turning soon - in plenty of time for Christmas).