Exabian

Member

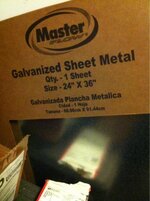

Has anyone used galvanized sheet metal as a inlay, like the sheets used on air ducts? If you have any helpful tips or warnings?

I haven't used it, but I wonder WHY you would choose that. Galvanized steel seems like a icky thing to turn, especially since you can pick up a 6" x 10ft roll of Aluminum flashing for a couple bucks - much more appealing for multiple reasons IMO.

galvanized steel is corrosion resistant, however as soon as you turn it you will expose the bare 'steel' underneath....

It will rust if not sealed properly so be careful...going to have to make sure it's completely dry...it might even pick up some moisture from the surrounding wood and rust anyway.

either way, it might be worth an attempt to see how it comes out.

#1 The material used to galvanize metal is toxic to humans so when you cut it be careful. safe in an inert state but the dust or fumes from cutting is not good.

#2 Steel is harder that alum. and IMHO should not be turned on a wood lathe again IMHO