egnald

Member

Greetings from Nebraska,

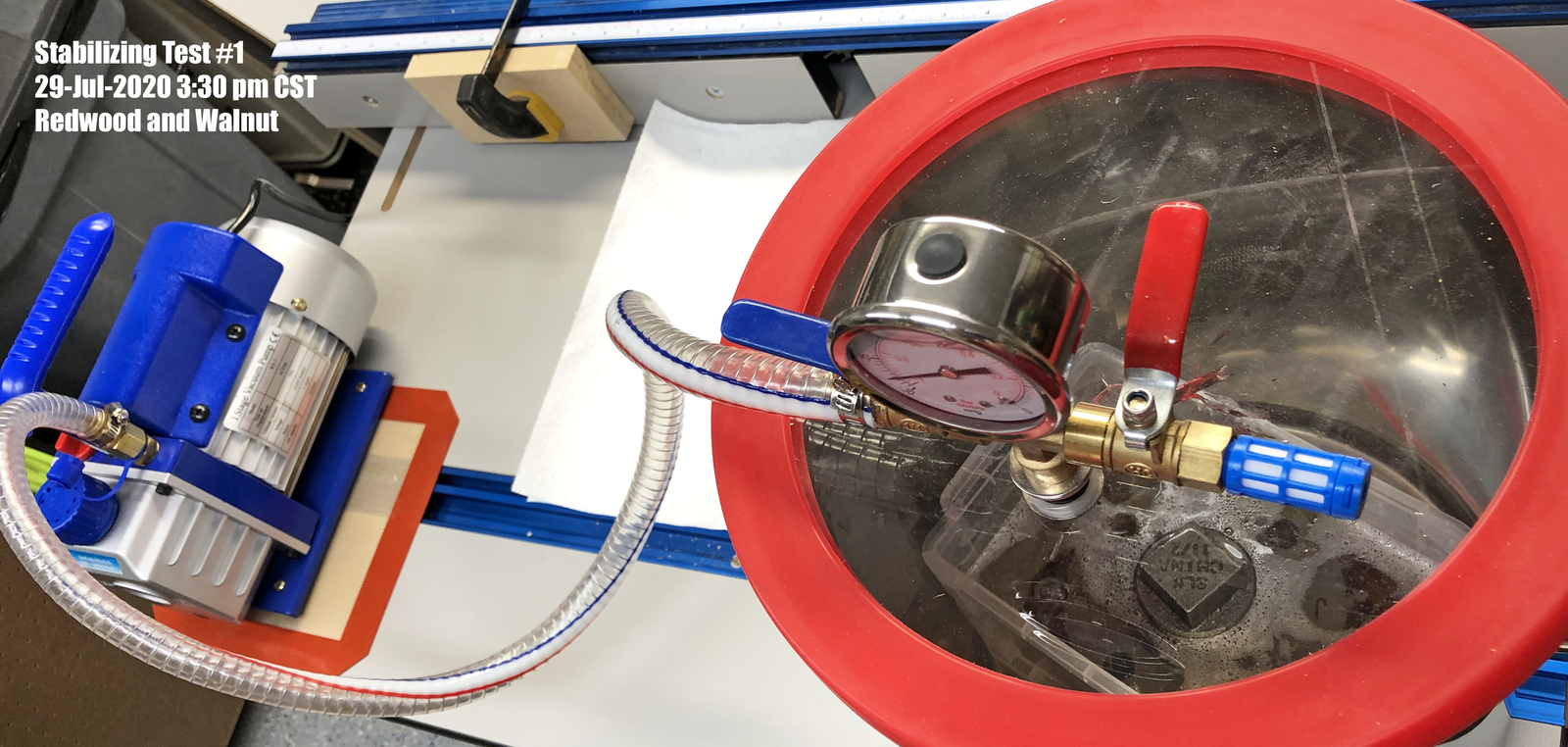

The title pretty much says it all - I have my trial batch of blanks (Redwood and Walnut) in my new stabilizing rig under vacuum with Cactus Juice. Prior I had dried them in my toaster oven at 220F for about 24 hours, then vacuum sealed them in bags while they were still hot. They have been under vacuum for about 30 minutes now and the foam that started out has now reduced to beer bubbles. I'm hoping it subsides by bedtime tonight (7 or 8 hours from now) so I can let the soaking process commence.

Regards,

Dave

Addendum: Disaster struck shortly after this post. The lid imploded (details in a later post)

The title pretty much says it all - I have my trial batch of blanks (Redwood and Walnut) in my new stabilizing rig under vacuum with Cactus Juice. Prior I had dried them in my toaster oven at 220F for about 24 hours, then vacuum sealed them in bags while they were still hot. They have been under vacuum for about 30 minutes now and the foam that started out has now reduced to beer bubbles. I'm hoping it subsides by bedtime tonight (7 or 8 hours from now) so I can let the soaking process commence.

Regards,

Dave

Addendum: Disaster struck shortly after this post. The lid imploded (details in a later post)

Last edited: