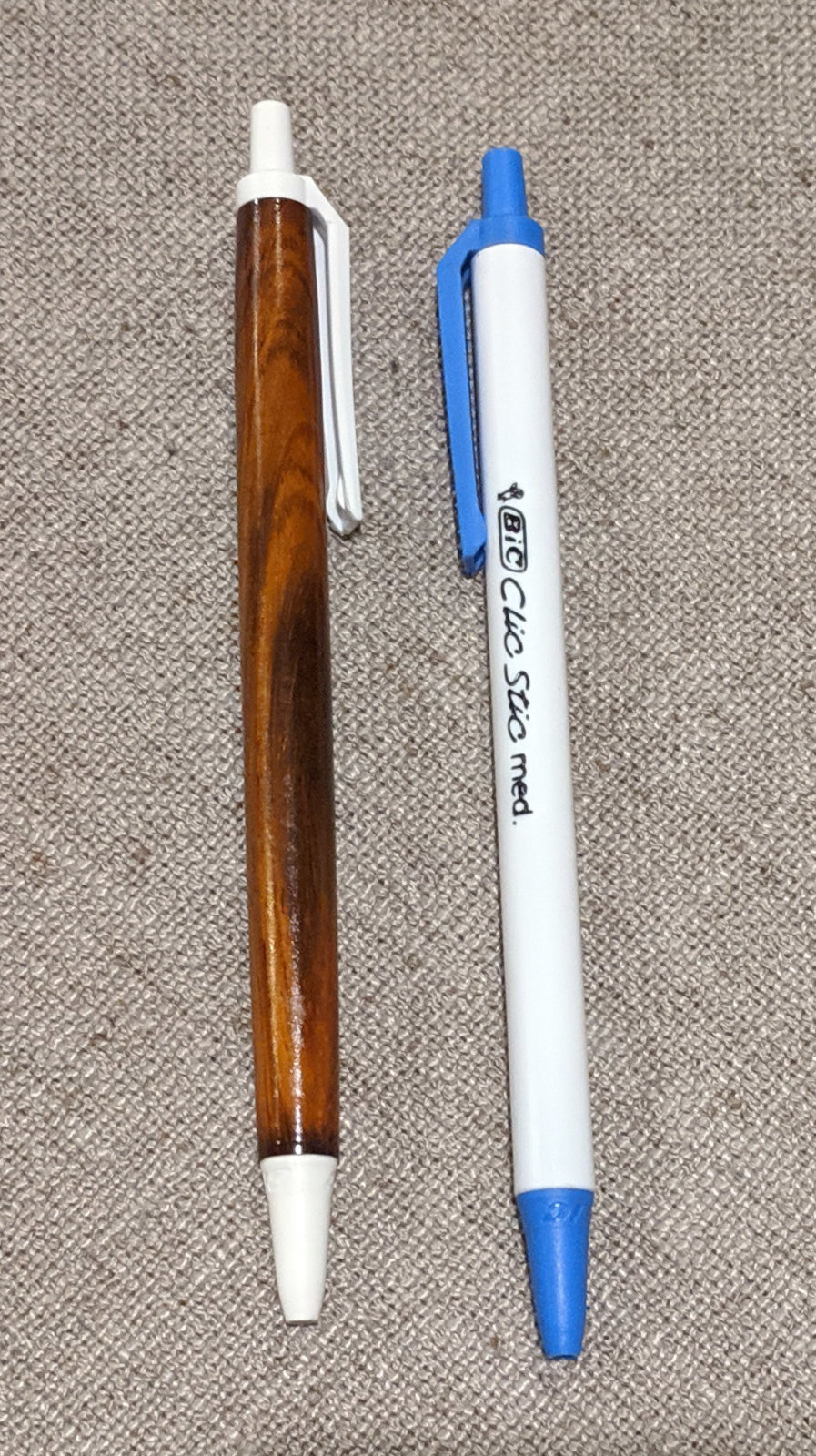

This is one that I've been meaning to try for a while. I'm certain it has been done by others, but to my knowledge it hasn't been shared on IAP. It is just a Bic Clic with the barrel replaced with Cocobolo. I had to drill the blank on the lathe from both ends because I didn't have an extra long bit. I also used a bit that was slightly small and then sanded the hole as needed to get the right fit. There's no brass tube or anything. With this one I fit the components after turning down to size, but next time I'll get the right fit before turning. The wood barrel is kind of fragile, I'm not sure how well it'll hold up. Next time I will probably drill the hole slightly oversized and then build up with CA to get a good press fit. I know doing a slip fit and gluing the components would work, but then you couldn't replace the ink if needed. I didn't spend much time on the finish, just threw a coat of CA. Anyway, it was fun trying something a little different.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cocobolo Bic Clic Stic

- Thread starter Dehn0045

- Start date

Signed-In Members Don't See This Ad

See more from Dehn0045

Signed-In Members Don't See This Ad

Bryguy

Member

Nice idea. Well executed!

darrin1200

Member

Looks like a good execution. I think you might have a long term fragility problem. If you drilled a large whole all the way through, the same size to fit end pieces, then it will be doubly fragile in the middle, because it is a thin walled wooden tube. Wood movement, moisture content (or lack of) along with impact and flex stresses will likely cause a failure down the road.

If you don't have a tube through the whole piece. You add can strength If you drill the through hole just big enough to fit the refill through. That will leave enough meat to be strong enough alone, although a CA seal would help it. The key is to insert some type of support in the ends where the wood is thinnest and the most stress is applied.

One method is to check all the pen kit dimensions, and find a brass tube that will be a tight fit, you can always loosen the fit with sandpaper. You can then cut this tube into small (approx 3/8 length) and glue them into the ends as reinforcement bushings.

Another option is to make your own bushing using acrylic. It can be fidley and needs practice, but can work. Once again, the goal is to reinforce the ends.

The third option, which is the one custom makers use all the time, is to sleeve your entire pen blank. Fit a piece of acrylic or ebonite all the way through your blank. This is no more difficult than drilling for your brass tube. The difficult part is turning the insert which is a long thin rod. The insert should be big enough to drill to size needed to fit your parts. Once your blank is prepared, dill through to fit the refill, and then drill each end to fit your cone and finial piece.

I think this is a great project to hone your skills. As you gain confidence, you can make your own nose cones. But be prepared, this is opening up a new rabbit hole of design that can easily draw you in.

Good luck

If you don't have a tube through the whole piece. You add can strength If you drill the through hole just big enough to fit the refill through. That will leave enough meat to be strong enough alone, although a CA seal would help it. The key is to insert some type of support in the ends where the wood is thinnest and the most stress is applied.

One method is to check all the pen kit dimensions, and find a brass tube that will be a tight fit, you can always loosen the fit with sandpaper. You can then cut this tube into small (approx 3/8 length) and glue them into the ends as reinforcement bushings.

Another option is to make your own bushing using acrylic. It can be fidley and needs practice, but can work. Once again, the goal is to reinforce the ends.

The third option, which is the one custom makers use all the time, is to sleeve your entire pen blank. Fit a piece of acrylic or ebonite all the way through your blank. This is no more difficult than drilling for your brass tube. The difficult part is turning the insert which is a long thin rod. The insert should be big enough to drill to size needed to fit your parts. Once your blank is prepared, dill through to fit the refill, and then drill each end to fit your cone and finial piece.

I think this is a great project to hone your skills. As you gain confidence, you can make your own nose cones. But be prepared, this is opening up a new rabbit hole of design that can easily draw you in.

Good luck

johncrane

Member

great job Sam! i have done the Bic none clic body in wood i never tried the Bik Clic