egnald

Member

Greetings fellow IAP members,

If you turn Cigar kits using bushings, you might not be aware of the following (for a long time I wasn't).

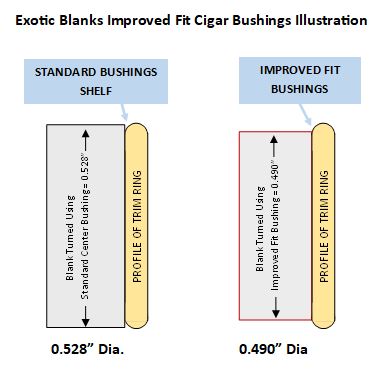

About a year ago, Ed from Exotic Blanks did a YouTube short video related to the lower-center bushing on Cigar pen kits and how the standard bushings leave a little "shelf" between the blank and the trim ring. Although the difference might seem subtle, I find a very noticable difference between the pens I made a few years ago with standard bushings and the ones I have made more recently. I drew this up to illustrate the difference for my own Cigar kit turning and assembly instructions. (I did my best to make the drawings to scale).

Although the same results can be achieved by using standard bushings followed by turning the center end of the lower blank down farther to the 0.490" diameter, I think using a set of Ed's Improved Fit (11A) bushings makes the job much easier. Here is a link to the Improved Fit Bushings that Exotic Blanks sells and a link to Ed's YouTube video Cigar Pen Design Improvement that explains them.

Regards,

Dave

If you turn Cigar kits using bushings, you might not be aware of the following (for a long time I wasn't).

About a year ago, Ed from Exotic Blanks did a YouTube short video related to the lower-center bushing on Cigar pen kits and how the standard bushings leave a little "shelf" between the blank and the trim ring. Although the difference might seem subtle, I find a very noticable difference between the pens I made a few years ago with standard bushings and the ones I have made more recently. I drew this up to illustrate the difference for my own Cigar kit turning and assembly instructions. (I did my best to make the drawings to scale).

Although the same results can be achieved by using standard bushings followed by turning the center end of the lower blank down farther to the 0.490" diameter, I think using a set of Ed's Improved Fit (11A) bushings makes the job much easier. Here is a link to the Improved Fit Bushings that Exotic Blanks sells and a link to Ed's YouTube video Cigar Pen Design Improvement that explains them.

Regards,

Dave