MesquiteMan

Retired Head Moderator

This is just a warning for those who think a HF pressure pot is safe...

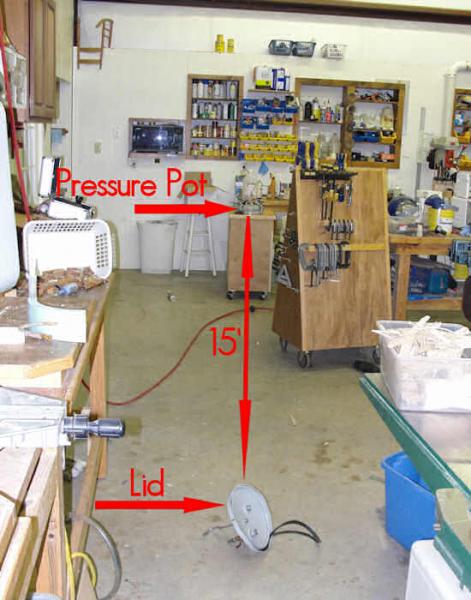

I was standing just 6' to the right of where this landed. I am normally sitting right next to the pots while casting. The lid flew 15' and the guage cover flew over 30' away.

I think I will try to straighten and re-use this lid!

Here you can clearly see the pressure relieve valve that did not do any good.

This is an indentation into 3/4" baltic birch plywood made by the clamps when they flew open at lift off!

The story...

Doing a little casting last night when all of a sudden, I heard a deafening bang. I had no idea what the hell had just happened so I hit the floor, thinking maybe terrorists were attacking my shop! After getting up and checking my shorts, I find the lid to my pressure pot 6' away from where I was standing! The lid was greatly deformed and the pressure gauge was missing a portion. I ended up finding parts of the gauge 30' away! Holly smokes, did that shake me up!

Normally, I am sitting right next to my PPs while casting. Thank GOD for some reason I decided to go over to my tablesaw and cut up some blanks. All kinds of things that are normally on my casting table were all over the shop. Even the chair I normally sit in was been hit by flying debris. Thank God my guardian angel was watching over me or I could possibly have been severely maimed (other than my damaged hearing!) or even worse. Wow, what a shock!

I have made a modification to my other pots to make them last longer. I take pieces of steel bar and cut them, then drill a dimple in them and epoxy them to the lid where the clamps tighten down. This helps keep the clamp screw from eventually digging into the lid and causing problems. You can see what I am talking about on the pot to the left in the second pic.

I have been using the pot that exploded for a while now and just last night decided to add the "pot saver" mod since the clamp screws were starting to dig into the lid. Normally, I use JB weld and glue the "pot savers" to the lid and let them sit overnight. This time, I was out of JB weld so i decided that I would just use hot glue since, as far as I knew, I just needed something to hold the "pot savers" in place until the clamps were tightened.

I installed the "pot savers" and then pressured it up. I went a little past the 80# where I normally cut it off (95# actually) but have done this many times in the past with no problems. I do have a pressure relief valve but I have it adjusted so it does not start leaking until 95# or so. In this case, it did not leak at all. Everything was fine and the pot was holding air. It blew 10 minutes or so later.

What I think happened...

I think that part of what holds the lid on with these pots is the little raised ring around the lid. As the lid expands just a little with pressure, the lip prevents the clamp from jumping off the pot. That is one of the reasons I put the dimple in my "pot savers". In previous cases, the JB weld has helped hold the "pot saver" and thus the clamp to the lid since it is rigid and actually creates a good bond. In this case, the hot glue just did not have the strength to keep the "pot savers" from slipping off the lid, allowing the clamps to open and launch the lid. I am not sure how that explains the severely warped lid, though.

Anyway, now I need to get a new PP and will certainly be re-thinking my casting procedure.

I was standing just 6' to the right of where this landed. I am normally sitting right next to the pots while casting. The lid flew 15' and the guage cover flew over 30' away.

I think I will try to straighten and re-use this lid!

Here you can clearly see the pressure relieve valve that did not do any good.

This is an indentation into 3/4" baltic birch plywood made by the clamps when they flew open at lift off!

The story...

Doing a little casting last night when all of a sudden, I heard a deafening bang. I had no idea what the hell had just happened so I hit the floor, thinking maybe terrorists were attacking my shop! After getting up and checking my shorts, I find the lid to my pressure pot 6' away from where I was standing! The lid was greatly deformed and the pressure gauge was missing a portion. I ended up finding parts of the gauge 30' away! Holly smokes, did that shake me up!

Normally, I am sitting right next to my PPs while casting. Thank GOD for some reason I decided to go over to my tablesaw and cut up some blanks. All kinds of things that are normally on my casting table were all over the shop. Even the chair I normally sit in was been hit by flying debris. Thank God my guardian angel was watching over me or I could possibly have been severely maimed (other than my damaged hearing!) or even worse. Wow, what a shock!

I have made a modification to my other pots to make them last longer. I take pieces of steel bar and cut them, then drill a dimple in them and epoxy them to the lid where the clamps tighten down. This helps keep the clamp screw from eventually digging into the lid and causing problems. You can see what I am talking about on the pot to the left in the second pic.

I have been using the pot that exploded for a while now and just last night decided to add the "pot saver" mod since the clamp screws were starting to dig into the lid. Normally, I use JB weld and glue the "pot savers" to the lid and let them sit overnight. This time, I was out of JB weld so i decided that I would just use hot glue since, as far as I knew, I just needed something to hold the "pot savers" in place until the clamps were tightened.

I installed the "pot savers" and then pressured it up. I went a little past the 80# where I normally cut it off (95# actually) but have done this many times in the past with no problems. I do have a pressure relief valve but I have it adjusted so it does not start leaking until 95# or so. In this case, it did not leak at all. Everything was fine and the pot was holding air. It blew 10 minutes or so later.

What I think happened...

I think that part of what holds the lid on with these pots is the little raised ring around the lid. As the lid expands just a little with pressure, the lip prevents the clamp from jumping off the pot. That is one of the reasons I put the dimple in my "pot savers". In previous cases, the JB weld has helped hold the "pot saver" and thus the clamp to the lid since it is rigid and actually creates a good bond. In this case, the hot glue just did not have the strength to keep the "pot savers" from slipping off the lid, allowing the clamps to open and launch the lid. I am not sure how that explains the severely warped lid, though.

Anyway, now I need to get a new PP and will certainly be re-thinking my casting procedure.

Attachments

Last edited: