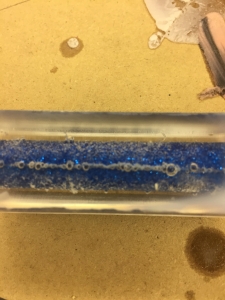

I use alumilite often. It works well with some things and not others. What I have found, when working with a material that may hold air in its pours, alumilite often sets before the air has time to escape. Under pressure it shouldn't be as big of an issue since the air is compresses. Don't assume this paper will work the same as stamps since they are made differently and stamps are probably thinner. If you use polyresin, give it a try. The extra curing time may be a huge help. If you only use Alumilite, try warming the resin to thin it down prior to mixing, also warm the blanks. I use shop clamp lights for both. The heat from the lamp will burn off any humidity from the blank material and dry it out just prior to pouring the resin. That will help the thin resin penetrate the pours of the material. It's all about trial and error. Keep notes each time so when you do find what works, you can repeat the process and be consistent. Good Luck!