robutacion

Member

Hi peoples,

This is not a new issue, infact I have created another thread on the subject, some years ago and spoke about it more times that I can count since however, I never expanded and exemplified/demonstrated the issue properly here on IAP so, what am I talking about, the "Flap disc system"...!:biggrin:

What is it...??? the system involves using a flap disc on a regular size grinder (4") and use it to handle blanks that are particularly difficult, fragile, soft, too hard, various materials glued together (segmentation). There is no reason why you couldn't use it for any other blanks you can think of but, where the system "shines" is with the handling of the difficult stuff...!

I have had many enquiries on how I turn and finish many of the difficult blanks I make, most of which I show a sample of as when they are going to turn them they have anything but troubles, and blowout after blowout. While this can happen to the best out there, I should "indicate" that, most of the problems are experience from new pen turners that haven't yet acquired the necessary expertise to know what to look for and how to deal with it.

The increase interest in pen blanks that are created with a combination of wood and resin are 70% of the culprits but, there are many other blanks that I put together using many different materials, with very different degrees of adhesion, density, hardness, workability such as most of the segmented blanks seen in our days.

Carbide tipped tools have become a big aid but, they don't resolve many issues that destroy most of the blanks, and that is a "catch" as small as it may be. The principle of the flap disc is that, you can use discs (blue or yellow) that are made to work with ANY materials out there so, they will handle those harder insertions within the blank composition, such as metal, wood, resin, brass, copper, aluminium, bone, leather, perspex, stone, etc, etc.....!

The flap disc is used with the lathe running at about 1.500rpm (more or less) the 2 centrifugal forces forces, rotating at the same time and in different directions, allow for quick removal of material, without excessive heat. Lower grits are better for cutting material, I use 40 grit but 60 grit is also OK while the finest grits such as 80, 100 and 120 are more for sanding or removing small amounts leaving a finer/better finish however, they will produce a lot more heat if used to CUT material, that will take a lot longer to achieve and the heat can compromise the adhesion of the brass to the blank material.

So, what does a flap disc looks like...???

What tool should be used to run the flap discs...???

There are 4" and 5" size flap discs so, any regular grinder of those sizes, will run it.

How much will it cost to set up the flap disc system...???

Well, if you are going only to work with wood, the red oxide flap discs are the cheapest and good enough for the job, you find them in most hardware stores however, they can be pricey there, you will find quality flap discs on ebay for half to 1/3 of the price. If you have blanks with a combination of various materials, I suggest you spend a little more and by the blue or yellow discs, they cost a few time more than the regular stuff but, you cut better anything you used them on, including wood that will last a long time is that is all you cut/work with. Again, eBay will offer you better prices...! A red oxide (regular) flap disc set you back about $2 and a better disc you would expect to pay about $10 for it, you will do 100 blanks before you have to replace it...!

As for the grinders, you can find the cheap anywhere, from $20 up, right to the quality brands that can cost a couple of hundred. You won't get better results with the most expensive grinder, you "may/should" get a lot more life out of the tool, though. So, you can be set up with a $25 investment right up to what you are comfortable to spend, most people have a regular 4" grinder so the investment is only on the disc...!

It is correct that, a flap disc working will make a considerable amount of dust (obviously), this can be a problem with some turners that work in very confined spaces and/or in situations where the lathe room is combined with other parts of the house where dust spread is a problem however, the dust issue is simply resolved by using a dust extractor with a large hood.

There are mini 2" flap discs available but, these are very expensive and made to be used in specific tools/specialized sanders that also cost a lot of money, why am I mentioning this...??? because, some people find the 4" grinder a little too big to handle for this purpose so, there is an economical way to get around it, using 2" sanding apparatus that are mostly used by panel beaters and what I'm talking about are these; (The last pic shows a pad that was originally 3" and that I cut to match the sanding disc size, this was the pad that I re-threaded to fit in the 4" grinder)

These are heavy duty discs that are specially made to use with those rubber pads, there go from 1" to 4" in diameter, with all kind of grits, the lower ones, very effective to be used as a flap disc however, they are slower to cut and leave a rougher finish, quite visible in a video clip I made yesterday Flap disc & mini sanding pads on a 4" grinder - YouTube

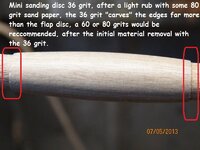

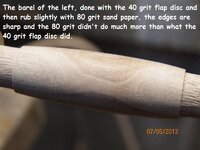

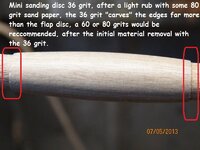

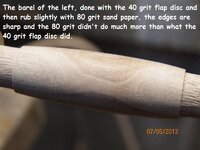

A few closer pics I took after the Walnut blanks was rubbed with some 80 grit sand paper as shown in the video. Where I call you attention to, is for the ends of the barrel that was done with the mini sanding discs with the 36 grit, the ends are not as sharp/clean as the blanks done with the flap disc with a 40 grit.

These small discs and pads are made to be used with air gun sanders, they (sanders) are really small and easy to handle and not that costly (sanders $60 to $80) however, contrary to what the factory recommendations say, the minimum of 8 CFS power from an air compressor, isn't enough, nor the the air volume these small compressors hold (5 to 30 litres), the air tools are useless with anything less than a 12 CFS and a minimum of 50 litres tank capacity...!

So, if you have a good compressor, these air gun sanders are great, unfortunately they don't make this size sanders to run on electricity however, "right angle" electric drills are available but not that common such as these

unfortunately they don't make this size sanders to run on electricity however, "right angle" electric drills are available but not that common such as these  the right size bolt or threaded rod cut to size, and those mini pads can be used without problem..!

the right size bolt or threaded rod cut to size, and those mini pads can be used without problem..!

And what about, adapting those small rubber pads on to a normal 4" grinder...???

Well, that is my preferred option to resolve the bulkiness of the 4" flap discs in some cases, and for that, you simply open the thread size of the pads to accommodate the grinder threaded shaft, most are M10 x 1.25 so, an easy and quick job and voila, you have a very inexpensive 2" sander done with easy handling and enough head clearance to reach tight spots or to avoid, hitting anything in your lathe, when in use...!

Now, it comes the fun part, I DARE YOU, to try to turn a pen blank out of Polystyrene, yes that white stuff that comes in so many boxes as "packing", with your turning gauges...!

Nothing but a 21mm square x 130mm long piece of Polystyrene, mounted by itself on the lathe, no supports in or out, no tubes inside the blank, absolutely nothing, try to round it to 15mm or so and have a smooth finish, if you are brave enough try to define the blank with grooves first as a pen look alike, right to 10mm thickness, then paint them with a black marker and cut your barrels to pen shape and size, yes, try that and let us know/show us, what happened...! :wink::biggrin:

:wink::biggrin:

Anything like this...????

After I finish it, I snapped it to show that was nothing inside the blanks to support it, the 2 pics before that, show exactly how the blank was attached to the lathe, no tricks...!

OK so, lets rep-up this thread/demonstration, by saying that, I'm a strong advocated for keeping alive the old wood working techniques, tools and principles however, I like to think that, one can use a little imagination to bypass some common problems, we see more and more , people resorting to any means possible to reach their goals and while wood turning by traditional methods is alive and well, metal lathes have in recent years been introduced to the world of pen making/turning/dressing and its used has been increasing considerably, and I don't believe those using a metal lathe to turn their pens are less of a pen worker, in fact, many years ago, a gentleman right here in Adelaide-South Australia, has invented a wood lathe that incorporated the principles of a wood and metal lathes combined, this lathe is called Symtec Symtec Wood Lathes.avi - YouTube no longer in production but still with many people out there using it successufuly...!

You have options, regardless if you agree, like it or not however, I believe this system that I so much talk about, have a place among many of us, particularly when dealing with those difficult blanks, is it worth the risk of losing the blank by blowing it out...??? in my view, no is not and that is the very reason why once again, I took the time to demonstrated to everyone that, it works...!

Good luck,

Cheers

George

This is not a new issue, infact I have created another thread on the subject, some years ago and spoke about it more times that I can count since however, I never expanded and exemplified/demonstrated the issue properly here on IAP so, what am I talking about, the "Flap disc system"...!:biggrin:

What is it...??? the system involves using a flap disc on a regular size grinder (4") and use it to handle blanks that are particularly difficult, fragile, soft, too hard, various materials glued together (segmentation). There is no reason why you couldn't use it for any other blanks you can think of but, where the system "shines" is with the handling of the difficult stuff...!

I have had many enquiries on how I turn and finish many of the difficult blanks I make, most of which I show a sample of as when they are going to turn them they have anything but troubles, and blowout after blowout. While this can happen to the best out there, I should "indicate" that, most of the problems are experience from new pen turners that haven't yet acquired the necessary expertise to know what to look for and how to deal with it.

The increase interest in pen blanks that are created with a combination of wood and resin are 70% of the culprits but, there are many other blanks that I put together using many different materials, with very different degrees of adhesion, density, hardness, workability such as most of the segmented blanks seen in our days.

Carbide tipped tools have become a big aid but, they don't resolve many issues that destroy most of the blanks, and that is a "catch" as small as it may be. The principle of the flap disc is that, you can use discs (blue or yellow) that are made to work with ANY materials out there so, they will handle those harder insertions within the blank composition, such as metal, wood, resin, brass, copper, aluminium, bone, leather, perspex, stone, etc, etc.....!

The flap disc is used with the lathe running at about 1.500rpm (more or less) the 2 centrifugal forces forces, rotating at the same time and in different directions, allow for quick removal of material, without excessive heat. Lower grits are better for cutting material, I use 40 grit but 60 grit is also OK while the finest grits such as 80, 100 and 120 are more for sanding or removing small amounts leaving a finer/better finish however, they will produce a lot more heat if used to CUT material, that will take a lot longer to achieve and the heat can compromise the adhesion of the brass to the blank material.

So, what does a flap disc looks like...???

What tool should be used to run the flap discs...???

There are 4" and 5" size flap discs so, any regular grinder of those sizes, will run it.

How much will it cost to set up the flap disc system...???

Well, if you are going only to work with wood, the red oxide flap discs are the cheapest and good enough for the job, you find them in most hardware stores however, they can be pricey there, you will find quality flap discs on ebay for half to 1/3 of the price. If you have blanks with a combination of various materials, I suggest you spend a little more and by the blue or yellow discs, they cost a few time more than the regular stuff but, you cut better anything you used them on, including wood that will last a long time is that is all you cut/work with. Again, eBay will offer you better prices...! A red oxide (regular) flap disc set you back about $2 and a better disc you would expect to pay about $10 for it, you will do 100 blanks before you have to replace it...!

As for the grinders, you can find the cheap anywhere, from $20 up, right to the quality brands that can cost a couple of hundred. You won't get better results with the most expensive grinder, you "may/should" get a lot more life out of the tool, though. So, you can be set up with a $25 investment right up to what you are comfortable to spend, most people have a regular 4" grinder so the investment is only on the disc...!

It is correct that, a flap disc working will make a considerable amount of dust (obviously), this can be a problem with some turners that work in very confined spaces and/or in situations where the lathe room is combined with other parts of the house where dust spread is a problem however, the dust issue is simply resolved by using a dust extractor with a large hood.

There are mini 2" flap discs available but, these are very expensive and made to be used in specific tools/specialized sanders that also cost a lot of money, why am I mentioning this...??? because, some people find the 4" grinder a little too big to handle for this purpose so, there is an economical way to get around it, using 2" sanding apparatus that are mostly used by panel beaters and what I'm talking about are these; (The last pic shows a pad that was originally 3" and that I cut to match the sanding disc size, this was the pad that I re-threaded to fit in the 4" grinder)

These are heavy duty discs that are specially made to use with those rubber pads, there go from 1" to 4" in diameter, with all kind of grits, the lower ones, very effective to be used as a flap disc however, they are slower to cut and leave a rougher finish, quite visible in a video clip I made yesterday Flap disc & mini sanding pads on a 4" grinder - YouTube

A few closer pics I took after the Walnut blanks was rubbed with some 80 grit sand paper as shown in the video. Where I call you attention to, is for the ends of the barrel that was done with the mini sanding discs with the 36 grit, the ends are not as sharp/clean as the blanks done with the flap disc with a 40 grit.

These small discs and pads are made to be used with air gun sanders, they (sanders) are really small and easy to handle and not that costly (sanders $60 to $80) however, contrary to what the factory recommendations say, the minimum of 8 CFS power from an air compressor, isn't enough, nor the the air volume these small compressors hold (5 to 30 litres), the air tools are useless with anything less than a 12 CFS and a minimum of 50 litres tank capacity...!

So, if you have a good compressor, these air gun sanders are great,

unfortunately they don't make this size sanders to run on electricity however, "right angle" electric drills are available but not that common such as these

unfortunately they don't make this size sanders to run on electricity however, "right angle" electric drills are available but not that common such as these  the right size bolt or threaded rod cut to size, and those mini pads can be used without problem..!

the right size bolt or threaded rod cut to size, and those mini pads can be used without problem..!And what about, adapting those small rubber pads on to a normal 4" grinder...???

Well, that is my preferred option to resolve the bulkiness of the 4" flap discs in some cases, and for that, you simply open the thread size of the pads to accommodate the grinder threaded shaft, most are M10 x 1.25 so, an easy and quick job and voila, you have a very inexpensive 2" sander done with easy handling and enough head clearance to reach tight spots or to avoid, hitting anything in your lathe, when in use...!

Now, it comes the fun part, I DARE YOU, to try to turn a pen blank out of Polystyrene, yes that white stuff that comes in so many boxes as "packing", with your turning gauges...!

Nothing but a 21mm square x 130mm long piece of Polystyrene, mounted by itself on the lathe, no supports in or out, no tubes inside the blank, absolutely nothing, try to round it to 15mm or so and have a smooth finish, if you are brave enough try to define the blank with grooves first as a pen look alike, right to 10mm thickness, then paint them with a black marker and cut your barrels to pen shape and size, yes, try that and let us know/show us, what happened...!

Anything like this...????

After I finish it, I snapped it to show that was nothing inside the blanks to support it, the 2 pics before that, show exactly how the blank was attached to the lathe, no tricks...!

OK so, lets rep-up this thread/demonstration, by saying that, I'm a strong advocated for keeping alive the old wood working techniques, tools and principles however, I like to think that, one can use a little imagination to bypass some common problems, we see more and more , people resorting to any means possible to reach their goals and while wood turning by traditional methods is alive and well, metal lathes have in recent years been introduced to the world of pen making/turning/dressing and its used has been increasing considerably, and I don't believe those using a metal lathe to turn their pens are less of a pen worker, in fact, many years ago, a gentleman right here in Adelaide-South Australia, has invented a wood lathe that incorporated the principles of a wood and metal lathes combined, this lathe is called Symtec Symtec Wood Lathes.avi - YouTube no longer in production but still with many people out there using it successufuly...!

You have options, regardless if you agree, like it or not however, I believe this system that I so much talk about, have a place among many of us, particularly when dealing with those difficult blanks, is it worth the risk of losing the blank by blowing it out...??? in my view, no is not and that is the very reason why once again, I took the time to demonstrated to everyone that, it works...!

Good luck,

Cheers

George