Wmcullen

Member

I'm not sure if this process is right or wrong; unique or common. But I want to share in case it's interesting. |

27: Customized Zero Clearance Bandsaw Peg Jig

last post- 26: Laser Engraving 1

(3d *.obj file attached)

When I want to add "dots" to a pen design this jig quickly chops thicker dowels into usable pegs.

The Problemlast post- 26: Laser Engraving 1

(3d *.obj file attached)

When I want to add "dots" to a pen design this jig quickly chops thicker dowels into usable pegs.

Cutting small pieces on the bandsaw is fast but pegs can disappear down the throat or roll off the table.

My Solution

(Not rocket surgery, just how I did it.)

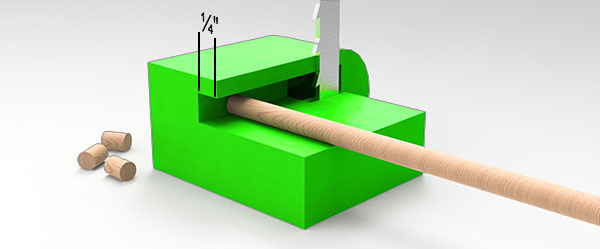

This 3d printed jig slides onto my bandsaw blade and sets the cut depth to about 0.25".

I hold the jig in place (not shown) while using, which keeps my fingers far away from the blade.

The pegs drop into a reservoir. When I'm done, the jig slides off and I pour the pieces out the back.

I glue the pegs into drilled holes, let dry and turn.

Summary

I could cut these 3/16" plugs by hand. But it's fun to over-engineer an answer sometimes.

Thanks for looking

- Cullen

Notes on 3D Printing

Some contributors in this group are master 3D printers. I'm not one of them, but I enjoy tinkering.

I'm happy to share this model as-is. It is the attached file: cutjig2.obj.

I turn my .obj files into gcode using Cura. When I import the model I always need to scale up by 10x and turn it to orient correctly.

Those who 3D print know that the direction of printing can be important.

Material is added one layer at a time, like legos, so everything should be supported as it prints or you could run into some problems.

This model was made to be printed with the curved "ceilings" on top. No support structures are needed if you print in this orientation.