Well, I've been trying to get better cuts with my bandsaw, and am now starting to make (for the moment very basic, but that will change) segmented pen blanks. The table for my Jet bandsaw is nice and large for its size, but I kept having trouble with the little red disc with the slot in it for the blade. I couldn't cut small segments without having them snap off that plate...either getting broken and shoved into the lower chamber, or fly off the table. I was also not getting perfectly strait cuts, and have mis-estimated the length of a couple wood blanks (which I normally only leave 1/16th extra length on, as they don't have the chipout potential on drilling like resins).

Anyway...this weeks project:

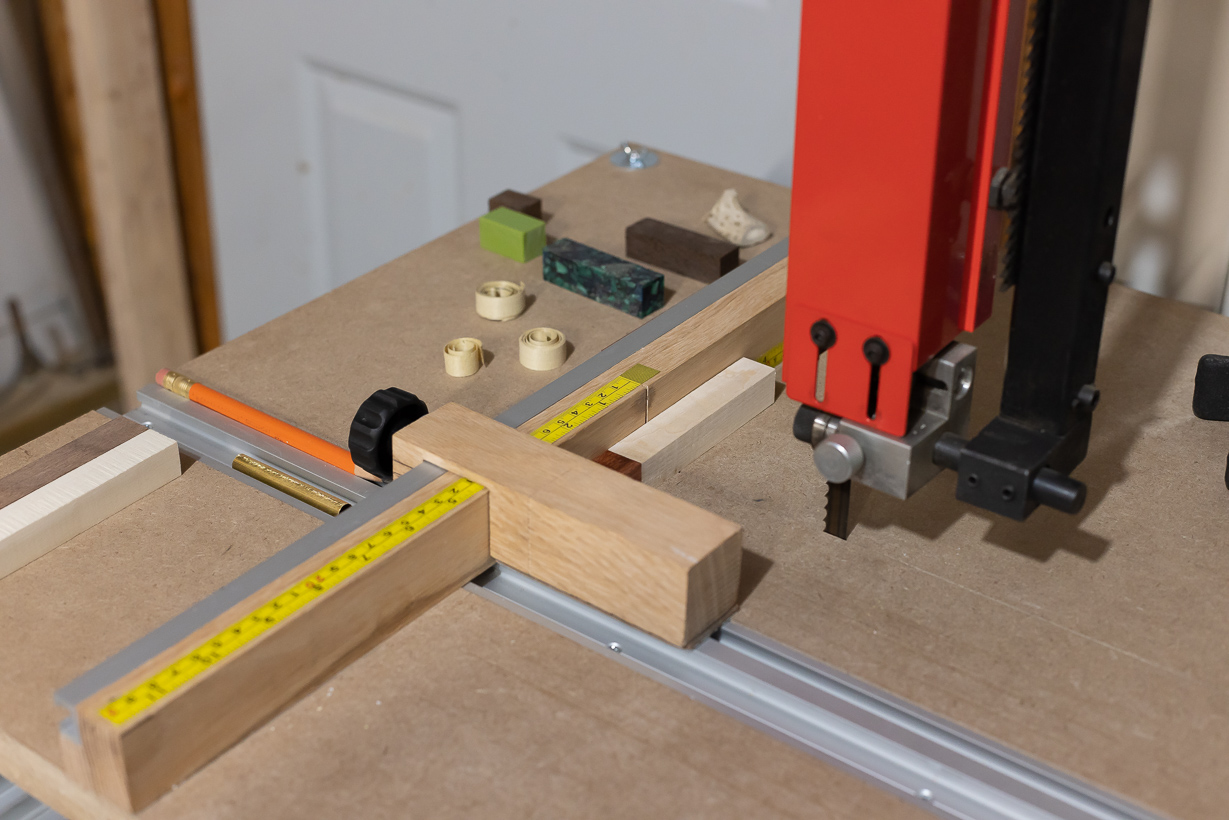

I've got some alternative ruler tape coming. I did not realize this stuff was actual measuring tape, and thus metal, with a sticky back. So it sits off the surface of the wood by about 1/64th. I have some ruler tape along the top, which is good when measuring and cutting tube-length blank segments. But for the really small segmenting pieces that I later assemble into a whole blank, if cut those small segments with the segment to the right of the blade, against the stop block I put together, they tend to get stuck between the blade and the stop block, and get destroyed. So I put another length of ruler tape on the other side, along the bottom front edge of the rail, so that I could measure and cut thin segments on the other side of the blade. That allows very thin segments (I've cut down to 1/16th so far) to be cut without worry they will get caught by the blade. But getting the blanks aligned on that ruler is tough, since its actually got some thickness...the blanks always catch the edge of the ruler tap.

I ordered another kind of ruler tape that appears to be paper thin (at most), and is a double-sided ruler, it starts at 0 in the middle, and stretches out to I think 24 inches on either side (so much more than I need). I intend to put that along the front edge of the rail (I'll probably manually cut it right along the 0 line, then align that edge right at the edge of the kerf I cut into the rail). That way I should be able to easily measure blanks on either side of the blade, whatever ends up being convenient for whatever it is I am cutting.

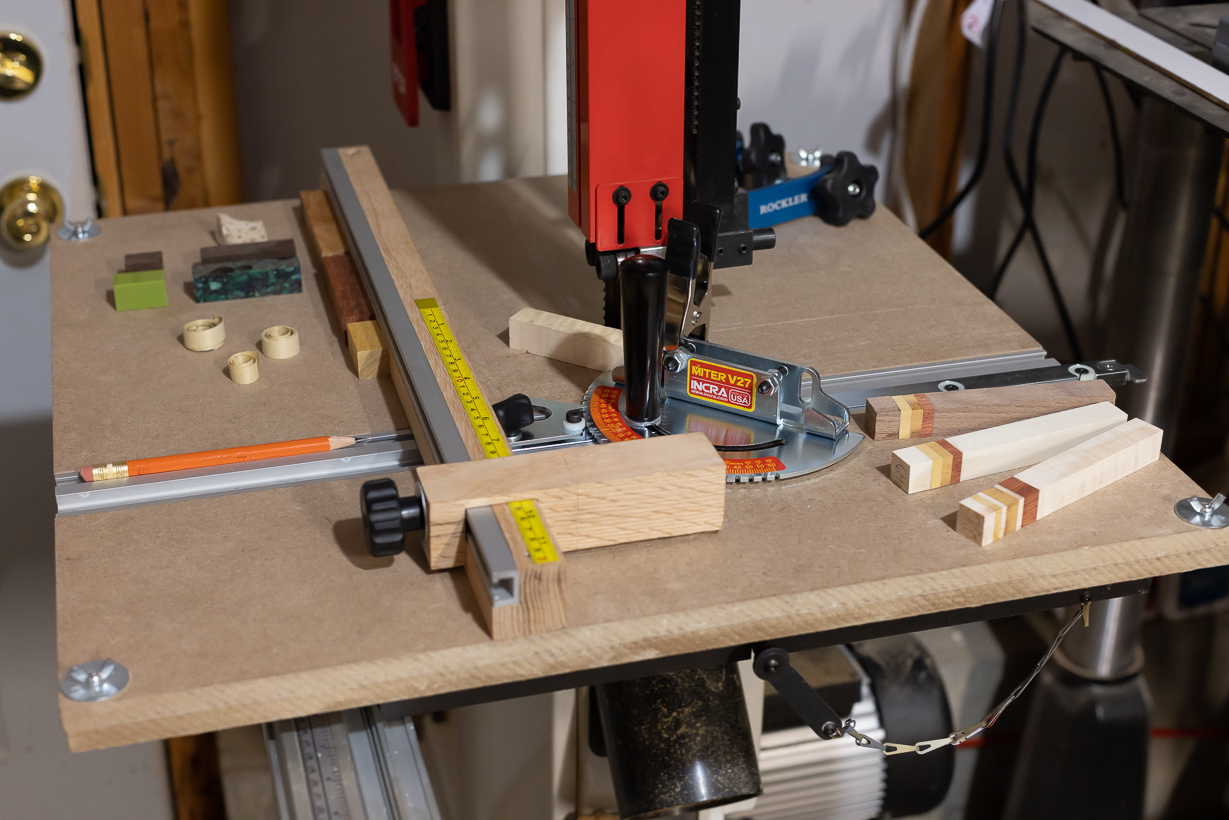

I also added a miter and 1/4" t-track to the base, so I can slide in (as you can see in the first photo) a miter gauge. I'll probably add some kind of basic T-Track fence to that, so that I can get better support of the blanks closer to the blade. I need something that I can slide in and out, though, as depending on the angle, the distance from the rail to the blade will differ. I may also need to flip the miter track around, as right now its a bit too far from the blade...I wasn't thinking when I screwed that in, and I ended up putting the miter track farthest from the blade, when I really wanted it the other way.

This is my first shop project. Got several ideas from several different places, various people's youtube videos on their own cross-cut sleds. I was going to make this out of a single piece of plywood originally, then when I realized that a 2x4' piece of birch plywood was $50, I decided on MDF. The thick MDF was also rather expensive, and I balked at that. The thinner stuff, that I used here, though, allowed me to think of a way to allow the top layer to be swapped out with different kinds of designs. I wanted the sled to be thick enough to have some heft, so I decided to stack the two halves once I cut them down to 2x2' square. The first thought was to glue them together, then I realized that since I did not have a router, I didn't have a good way to cut into the base...for any purpose. I at least needed to be able to cut a trough for the miter and t-track that is set into the base, and eventually I thought I might have other needs that might warrant different miter and t-track configurations. So I bolted the top layer of MDF on. I can swap that out for another layer that is designed differently in the future, if I need to. I can also take off the horizontal cross-cut stop, and just use the miter gauge if I need to. I could create another cross-cut stop that is designed in a different way if I need as well.

Anyway. Was a fun build. It will definitely help when I need to create a large order of pens...cutting blanks down to size with this is a synch, and I can cut them down to very accurate measurements. Eventually, when I get into segmenting, it should help me cut the segments at exact angles & thicknesses and all that as well. I have been concerned about getting exactly the right kerfs in segmented projects, like say a celtic knot, where if your kerf isn't exactly the same thickness as your segmenting material, then when you go to cut the other angles you end up offsetting the priors...a "broken knot" in other words. I am hoping now that I have precise control over exact measurements and such, that I'll be able to cut notches of exact thickness as well. I guess I'll see in the coming weeks here.

Anyway...this weeks project:

I've got some alternative ruler tape coming. I did not realize this stuff was actual measuring tape, and thus metal, with a sticky back. So it sits off the surface of the wood by about 1/64th. I have some ruler tape along the top, which is good when measuring and cutting tube-length blank segments. But for the really small segmenting pieces that I later assemble into a whole blank, if cut those small segments with the segment to the right of the blade, against the stop block I put together, they tend to get stuck between the blade and the stop block, and get destroyed. So I put another length of ruler tape on the other side, along the bottom front edge of the rail, so that I could measure and cut thin segments on the other side of the blade. That allows very thin segments (I've cut down to 1/16th so far) to be cut without worry they will get caught by the blade. But getting the blanks aligned on that ruler is tough, since its actually got some thickness...the blanks always catch the edge of the ruler tap.

I ordered another kind of ruler tape that appears to be paper thin (at most), and is a double-sided ruler, it starts at 0 in the middle, and stretches out to I think 24 inches on either side (so much more than I need). I intend to put that along the front edge of the rail (I'll probably manually cut it right along the 0 line, then align that edge right at the edge of the kerf I cut into the rail). That way I should be able to easily measure blanks on either side of the blade, whatever ends up being convenient for whatever it is I am cutting.

I also added a miter and 1/4" t-track to the base, so I can slide in (as you can see in the first photo) a miter gauge. I'll probably add some kind of basic T-Track fence to that, so that I can get better support of the blanks closer to the blade. I need something that I can slide in and out, though, as depending on the angle, the distance from the rail to the blade will differ. I may also need to flip the miter track around, as right now its a bit too far from the blade...I wasn't thinking when I screwed that in, and I ended up putting the miter track farthest from the blade, when I really wanted it the other way.

This is my first shop project. Got several ideas from several different places, various people's youtube videos on their own cross-cut sleds. I was going to make this out of a single piece of plywood originally, then when I realized that a 2x4' piece of birch plywood was $50, I decided on MDF. The thick MDF was also rather expensive, and I balked at that. The thinner stuff, that I used here, though, allowed me to think of a way to allow the top layer to be swapped out with different kinds of designs. I wanted the sled to be thick enough to have some heft, so I decided to stack the two halves once I cut them down to 2x2' square. The first thought was to glue them together, then I realized that since I did not have a router, I didn't have a good way to cut into the base...for any purpose. I at least needed to be able to cut a trough for the miter and t-track that is set into the base, and eventually I thought I might have other needs that might warrant different miter and t-track configurations. So I bolted the top layer of MDF on. I can swap that out for another layer that is designed differently in the future, if I need to. I can also take off the horizontal cross-cut stop, and just use the miter gauge if I need to. I could create another cross-cut stop that is designed in a different way if I need as well.

Anyway. Was a fun build. It will definitely help when I need to create a large order of pens...cutting blanks down to size with this is a synch, and I can cut them down to very accurate measurements. Eventually, when I get into segmenting, it should help me cut the segments at exact angles & thicknesses and all that as well. I have been concerned about getting exactly the right kerfs in segmented projects, like say a celtic knot, where if your kerf isn't exactly the same thickness as your segmenting material, then when you go to cut the other angles you end up offsetting the priors...a "broken knot" in other words. I am hoping now that I have precise control over exact measurements and such, that I'll be able to cut notches of exact thickness as well. I guess I'll see in the coming weeks here.