bfrazier

Member

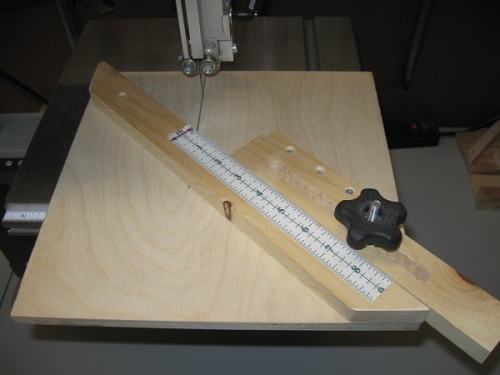

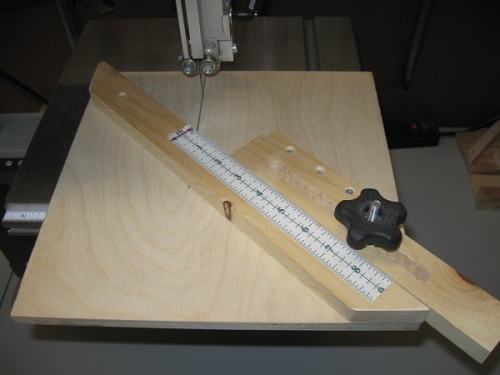

I finally had to come up with a solid means of making segments especially Celtic knots. It serves the purpose and is very adjustable for various sized blanks. This version will only do 45 Degree cuts; however, I'm working on an adjustable version with the same locking methodology that could come in handy.

View in Gallery

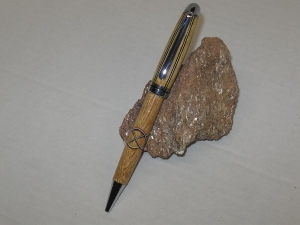

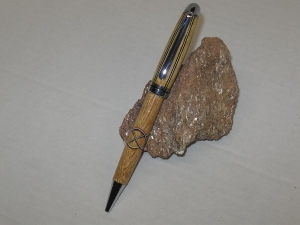

I think the results are pretty good. This upper is several pieces of veneer glued the glued by halves. The lower knot done with a two-tone gift card. Next one will be metal and veneer.

View in Gallery

Your suggestions are always welcome, and have helped me improve my stills and enjoyment very much.

Brian

View in Gallery

I think the results are pretty good. This upper is several pieces of veneer glued the glued by halves. The lower knot done with a two-tone gift card. Next one will be metal and veneer.

View in Gallery

Your suggestions are always welcome, and have helped me improve my stills and enjoyment very much.

Brian