*** pictures below ***

I just failed at drilling out fauxstone blanks for a majestic pen kit. My strategy was:

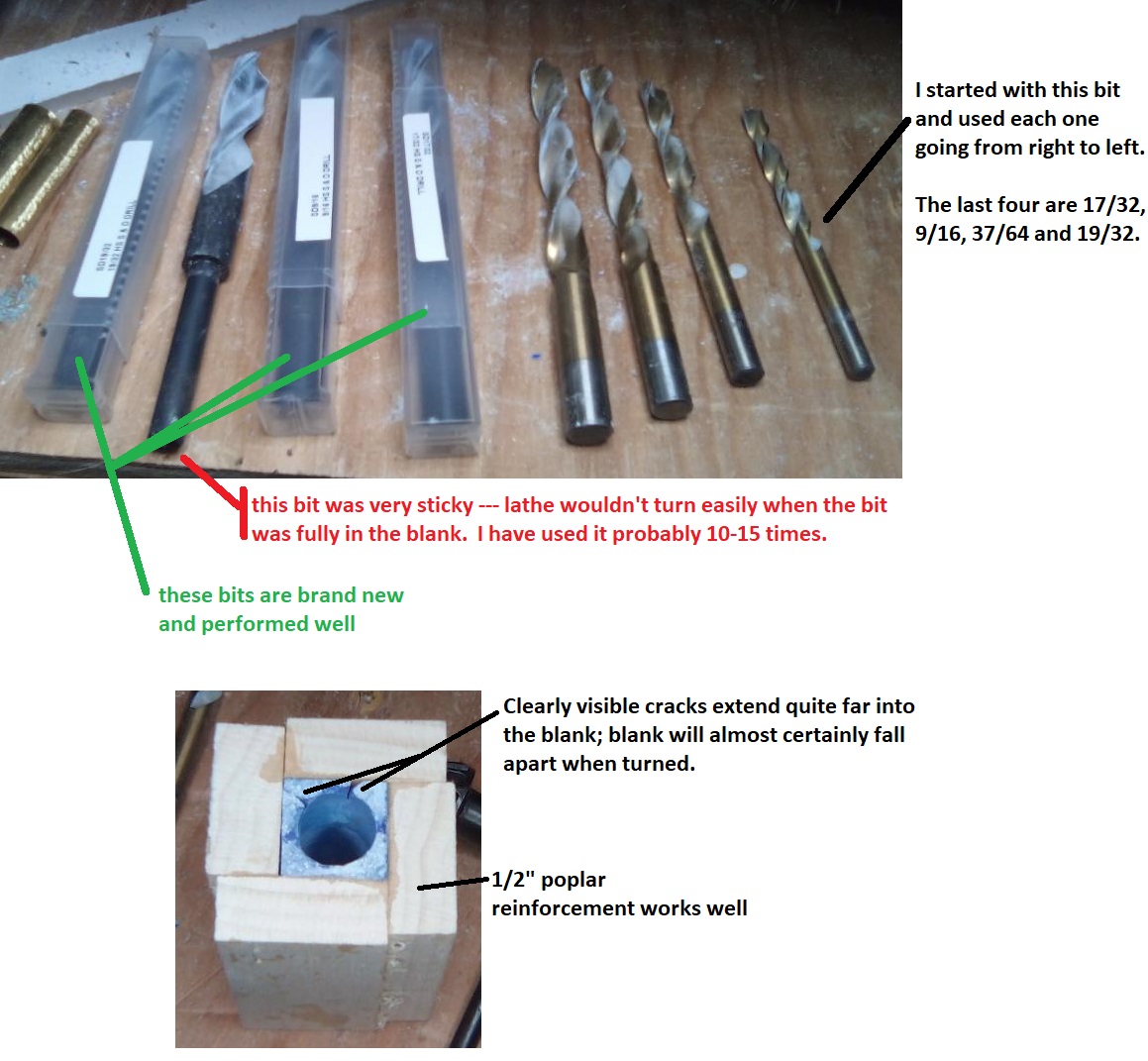

(a) reinforce the blank with 1/2" poplar

(b) drill on the lathe using 8 progressively larger bits. The last four bits were in increments as low as 1/64"

I was running the RPM around 300.

The results were not particularly appealing, with a close inspection revealing lots of cracks.

I invite all suggestions. My initial thoughts are focused on the last four drill bits:

(a) Drill bits #5, #6 and #8 are high speed steel brand new right out of the box. They were purchased from DrillAmerica

(b) I have had drill bit #7 for several weeks and have used it 10-15 times destroying trustone & fauxstone blanks. It was this one: https://www.exoticblanks.com/37-64-drill-bit-reduced-shank.html

I noticed that drill bit #7 was difficult to use. Compared to the other three, it seemed to generate a lot of resistance and eventually the lathe just stopped. To extract the bit from the blank I had to resort to a lot of twisting by hand. My guess is that's when a lot of damage occurred but I can't be certain.

My guess is that #7 needs to be sharpened, but I would appreciate the thoughts of those more experienced than me.

I just failed at drilling out fauxstone blanks for a majestic pen kit. My strategy was:

(a) reinforce the blank with 1/2" poplar

(b) drill on the lathe using 8 progressively larger bits. The last four bits were in increments as low as 1/64"

I was running the RPM around 300.

The results were not particularly appealing, with a close inspection revealing lots of cracks.

I invite all suggestions. My initial thoughts are focused on the last four drill bits:

(a) Drill bits #5, #6 and #8 are high speed steel brand new right out of the box. They were purchased from DrillAmerica

(b) I have had drill bit #7 for several weeks and have used it 10-15 times destroying trustone & fauxstone blanks. It was this one: https://www.exoticblanks.com/37-64-drill-bit-reduced-shank.html

I noticed that drill bit #7 was difficult to use. Compared to the other three, it seemed to generate a lot of resistance and eventually the lathe just stopped. To extract the bit from the blank I had to resort to a lot of twisting by hand. My guess is that's when a lot of damage occurred but I can't be certain.

My guess is that #7 needs to be sharpened, but I would appreciate the thoughts of those more experienced than me.