mark james

IAP Collection, Curator

One of the benefits of driving 2,500 miles and turning the phone on vibrate and the radio off... Nothing to do but think, ponder, imagine... I came up with a few ideas.

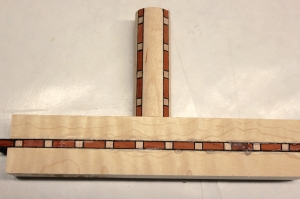

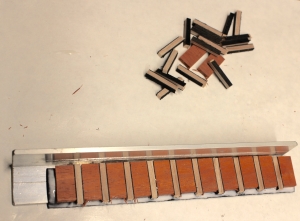

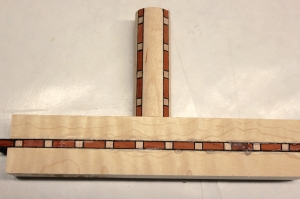

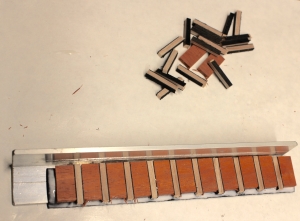

This is a new inlay design. It is a bit "clunky" for my tastes - too thick, but I can fix that! It fits for my .20" inlay objective, but this design will be better suited (IMO) with a thinner inlay on all 4 sides (.175" x .175" ??).

I have 4 more design modifications on this type of platform gluing up.

Please - all comments, suggestions, critique is beneficial... I will post all procedures on how I did this, so let's tweak it together!

View in Gallery

View in Gallery

View in Gallery

View in Gallery

View in Gallery

This is a new inlay design. It is a bit "clunky" for my tastes - too thick, but I can fix that! It fits for my .20" inlay objective, but this design will be better suited (IMO) with a thinner inlay on all 4 sides (.175" x .175" ??).

I have 4 more design modifications on this type of platform gluing up.

Please - all comments, suggestions, critique is beneficial... I will post all procedures on how I did this, so let's tweak it together!

View in Gallery

View in Gallery

View in Gallery

View in Gallery

View in Gallery

Last edited: