iamrohn

Member

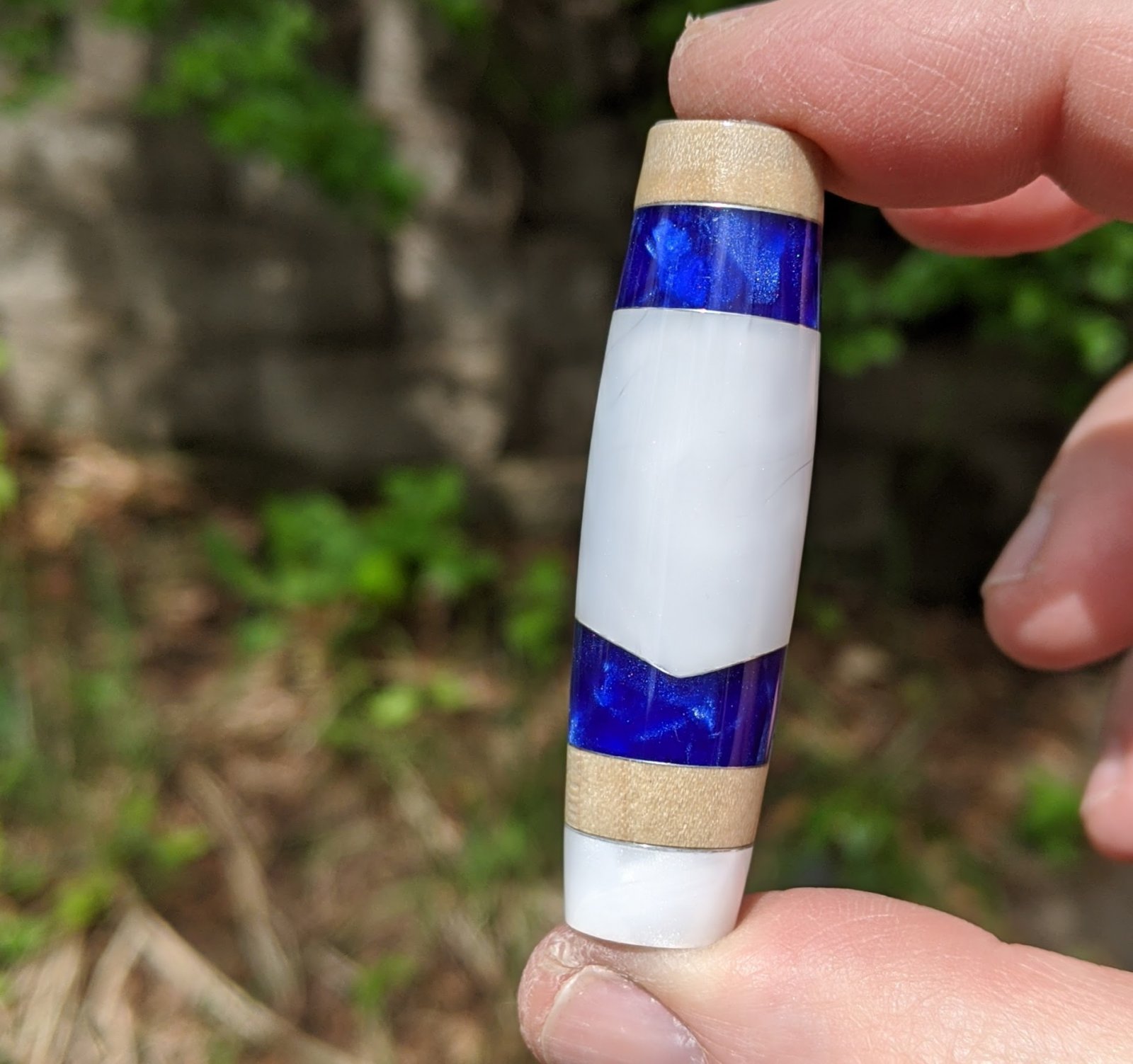

I [temporarily perhaps] abandoned my quest of gluing Mylanta plastic (HDPE) and instead turned to more easier to work with materials. This is the first time I've tried a soda pop can as accents... it was a lot easier to use, though I think I might go two or even three layers thick for future blanks.

I had this brass tube (Gatsby) available, but I don't have a kit to fit it currently. I think it's asking for something chrome heavy.

The pattern/design is patterned (copied?) from a Steve Kondo blank I saw on Turner's Warehouse's site. His is, of course, a lot more refined.

I think I like this one... the enlargement of the photo shows a lot more blemishes than you can see in person. This one was a very looooong ride. I made a number of stupid mistakes (including messing up the order of the pattern as I glued and needing to recut). My jigs aren't improving much yet, but I'm learning to use a lot more notes than I had, and keeping them right at hand on the gluing table

I'm sure there's an easier way, but my approach so far has been to glue two sections together, drill them so that I can square them, then glue on another, drill it and square it, etc.

(it reminds me of a sailboat for some reason)

I'm getting near the usable bottom of the grab bag of acrylic cutoffs purchased from Woodcraft, I might have two maybe three challenges left before I replenish (or get very challenged!).

I had this brass tube (Gatsby) available, but I don't have a kit to fit it currently. I think it's asking for something chrome heavy.

The pattern/design is patterned (copied?) from a Steve Kondo blank I saw on Turner's Warehouse's site. His is, of course, a lot more refined.

I think I like this one... the enlargement of the photo shows a lot more blemishes than you can see in person. This one was a very looooong ride. I made a number of stupid mistakes (including messing up the order of the pattern as I glued and needing to recut). My jigs aren't improving much yet, but I'm learning to use a lot more notes than I had, and keeping them right at hand on the gluing table

I'm sure there's an easier way, but my approach so far has been to glue two sections together, drill them so that I can square them, then glue on another, drill it and square it, etc.

(it reminds me of a sailboat for some reason)

I'm getting near the usable bottom of the grab bag of acrylic cutoffs purchased from Woodcraft, I might have two maybe three challenges left before I replenish (or get very challenged!).