SteveJ

Member

Here are the entries into the kitless contest. Please vote for your favorite. There will be one round of voting. One vote per person.

Prizes are:

First Place, Diamond Blanks from Mckenzie Pen Works $85.00 value and A PRESSURE POT SHELF FROM BeeAMaker

Second Place, $50 gift certificate from Rockler, and AAW membership from AAW $35 value

Third place, BOB from Karl 99 $50 value

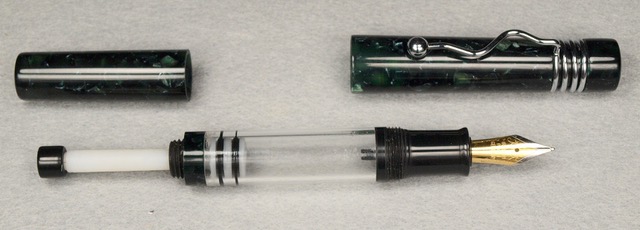

Pen one

Here is my first syringe piston filler. The body and cap are made from green acrylic blank with a clear cast acrylic ink window, The section is black acrylic with an IPG medium nib. The plunger is white acetal with two Buna-N o-rings. I liked the squiggly springy clip from an old giveaway pen so I decided to put it on this pen. Getting the fit between the o-rings and the ID was a challenge the o-rings are lubricated with silicone grease.

The overall length is 5 7/8 inches long and the pen is 5 1/8 inches uncapped.

Pen Two

This is my kitless pen entry. I started with a 9 inch Alumilite blank. First I made the section by turning a tenon for a 9mm thread to screw into the lower body. I drilled a hole to accept the converter for a friction fit. I then parted the section and turning it around where I drilled and reamed three steps of holes to accept the housing and threads for the housing. Then I created the lower body by first cutting a tenon to accept a triple start m13 die for the cap to body threads. I then drilled out the lower body and threaded it to accept the length and thickness of the converter and the screwed in section. I then drilled out the cap for the m13 triple start tap. After tapping the hole I trimmed some from the barrel to make sure the pattern on the lower barrel and the cap would match as well as I could make it when capped. I then used three sizes of mandrels to shape all three pieces as well as sand, finish, and polish the pieces. I also put a taper on the lower body to make sure that the cap could easily post on the end of the pen while writing. The nib is a #6 JOWO nib and is a semi-flex steel gold plated nib.

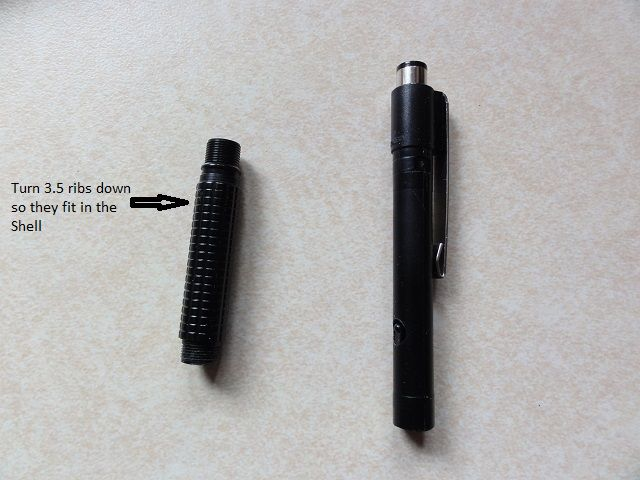

Pen Three

When making the .30-06 pen with the Zebra F-301 pen I start by taking the pen apart and removing the stainless tube. The lower ribbed part has to have 3.5 ribs turned down to fit into the shell where the bullet was. This makes the length right and the nib protrudes the correct distance when the clicker is pushed.

The clicked and the pen nib need to be removed. They are chromed brass and sanding removes the chrome. them polish to desired sheen. For the .30-06 shell I remove the primer and mount it in the chuck and take the letter "O" size drill to drill through the end. Mount it on the lathe and sand and polish it.

Put it together and enjoy.

Pen Four

This pen has no brass tube. The barrel is Chechen wood with colored veneer strips. We start with a pen blank (Chechen) which has an accurately square cross-section. Diagonal grooves (0.25" wide, 0.30" deep) are milled on each side at a 7 degree angle to the axis. Four Groups of 11 Colored veneer strips are inlaid on edge into grooves and secured with liberal amounts of thin CA. Each veneer strip group is a tight fit in its groove. After rounding on lathe, drilling is done (also on lathe) to accommodate Parker refill, spring, and click mechanism (like Slimline Pro). The hardware fittings (nib, upper finial, and push button) are machined from brass rod stock. The nib and finial pieces are from hexagonal stock. The hexagonal shape provides roll-stopping. The barrel is turned down to a diameter that matches the minimum diameter of the hexagon. The barrel is finished with multiple layers of thin CA, sanded and polished.

Notice the interesting shape that the veneer groups take on due to their diagonal placement and subsequent rounding of the barrel. Also notice that sharp corners on the brass nib and finial are removed (on lathe) and this results in pleasing shape with diamond-like patterning.

Pen Five

Here are the pictures of my entry for the 2019 Bash Kitless contest. Not perfect by any mean but I had a lot of fun making it. My first entry in this contest ever, probably won't be the last!

The wood is Golden amboyna burl (reinforced with brass tubes on the inside). There are two types of plastic for the parts I made, the body and cap threads (M13x0.8-triple) are black ebonite, the nib section, center bands, and finials are blue French Galalith. The parts I did not make myself are the clip, the housing/feed/black nib, and the ink converter.

Pen Six

This is my submission for the kitless pen contest. It is made of black

ebonite. I decorated it with precious leaves and powder (mainly silver,

but also palladium, gold and bronze), with white and blue

mother-of-pearl. The clip has been made by Mike from silver Pen Parts.

CA finish.

VOTE FOR ONE PEN!!!

Prizes are:

First Place, Diamond Blanks from Mckenzie Pen Works $85.00 value and A PRESSURE POT SHELF FROM BeeAMaker

Second Place, $50 gift certificate from Rockler, and AAW membership from AAW $35 value

Third place, BOB from Karl 99 $50 value

Pen one

Here is my first syringe piston filler. The body and cap are made from green acrylic blank with a clear cast acrylic ink window, The section is black acrylic with an IPG medium nib. The plunger is white acetal with two Buna-N o-rings. I liked the squiggly springy clip from an old giveaway pen so I decided to put it on this pen. Getting the fit between the o-rings and the ID was a challenge the o-rings are lubricated with silicone grease.

The overall length is 5 7/8 inches long and the pen is 5 1/8 inches uncapped.

Pen Two

This is my kitless pen entry. I started with a 9 inch Alumilite blank. First I made the section by turning a tenon for a 9mm thread to screw into the lower body. I drilled a hole to accept the converter for a friction fit. I then parted the section and turning it around where I drilled and reamed three steps of holes to accept the housing and threads for the housing. Then I created the lower body by first cutting a tenon to accept a triple start m13 die for the cap to body threads. I then drilled out the lower body and threaded it to accept the length and thickness of the converter and the screwed in section. I then drilled out the cap for the m13 triple start tap. After tapping the hole I trimmed some from the barrel to make sure the pattern on the lower barrel and the cap would match as well as I could make it when capped. I then used three sizes of mandrels to shape all three pieces as well as sand, finish, and polish the pieces. I also put a taper on the lower body to make sure that the cap could easily post on the end of the pen while writing. The nib is a #6 JOWO nib and is a semi-flex steel gold plated nib.

Pen Three

When making the .30-06 pen with the Zebra F-301 pen I start by taking the pen apart and removing the stainless tube. The lower ribbed part has to have 3.5 ribs turned down to fit into the shell where the bullet was. This makes the length right and the nib protrudes the correct distance when the clicker is pushed.

The clicked and the pen nib need to be removed. They are chromed brass and sanding removes the chrome. them polish to desired sheen. For the .30-06 shell I remove the primer and mount it in the chuck and take the letter "O" size drill to drill through the end. Mount it on the lathe and sand and polish it.

Put it together and enjoy.

Pen Four

This pen has no brass tube. The barrel is Chechen wood with colored veneer strips. We start with a pen blank (Chechen) which has an accurately square cross-section. Diagonal grooves (0.25" wide, 0.30" deep) are milled on each side at a 7 degree angle to the axis. Four Groups of 11 Colored veneer strips are inlaid on edge into grooves and secured with liberal amounts of thin CA. Each veneer strip group is a tight fit in its groove. After rounding on lathe, drilling is done (also on lathe) to accommodate Parker refill, spring, and click mechanism (like Slimline Pro). The hardware fittings (nib, upper finial, and push button) are machined from brass rod stock. The nib and finial pieces are from hexagonal stock. The hexagonal shape provides roll-stopping. The barrel is turned down to a diameter that matches the minimum diameter of the hexagon. The barrel is finished with multiple layers of thin CA, sanded and polished.

Notice the interesting shape that the veneer groups take on due to their diagonal placement and subsequent rounding of the barrel. Also notice that sharp corners on the brass nib and finial are removed (on lathe) and this results in pleasing shape with diamond-like patterning.

Pen Five

Here are the pictures of my entry for the 2019 Bash Kitless contest. Not perfect by any mean but I had a lot of fun making it. My first entry in this contest ever, probably won't be the last!

The wood is Golden amboyna burl (reinforced with brass tubes on the inside). There are two types of plastic for the parts I made, the body and cap threads (M13x0.8-triple) are black ebonite, the nib section, center bands, and finials are blue French Galalith. The parts I did not make myself are the clip, the housing/feed/black nib, and the ink converter.

Pen Six

This is my submission for the kitless pen contest. It is made of black

ebonite. I decorated it with precious leaves and powder (mainly silver,

but also palladium, gold and bronze), with white and blue

mother-of-pearl. The clip has been made by Mike from silver Pen Parts.

CA finish.

VOTE FOR ONE PEN!!!

Attachments

-

FP16-1.jpeg51.2 KB · Views: 1,134

FP16-1.jpeg51.2 KB · Views: 1,134 -

FP16-2.jpeg48 KB · Views: 808

FP16-2.jpeg48 KB · Views: 808 -

FP16-3.jpeg44.2 KB · Views: 803

FP16-3.jpeg44.2 KB · Views: 803 -

kitlessrr1.jpg87.3 KB · Views: 815

kitlessrr1.jpg87.3 KB · Views: 815 -

kitlessrr2.jpg72.6 KB · Views: 806

kitlessrr2.jpg72.6 KB · Views: 806 -

kitlessrr3.jpg69.2 KB · Views: 772

kitlessrr3.jpg69.2 KB · Views: 772 -

image.png455.3 KB · Views: 748

image.png455.3 KB · Views: 748 -

image (1).png357 KB · Views: 796

image (1).png357 KB · Views: 796 -

image (2).png534.6 KB · Views: 747

image (2).png534.6 KB · Views: 747 -

datauri-file.jpeg363.9 KB · Views: 725

datauri-file.jpeg363.9 KB · Views: 725 -

datauri-file (1).jpeg121.9 KB · Views: 776

datauri-file (1).jpeg121.9 KB · Views: 776 -

datauri-file (2).jpeg118.7 KB · Views: 728

datauri-file (2).jpeg118.7 KB · Views: 728 -

kitless1-BASHfeb19.jpg110.8 KB · Views: 1,221

kitless1-BASHfeb19.jpg110.8 KB · Views: 1,221 -

kitless2-BASHfeb19.jpg142 KB · Views: 887

kitless2-BASHfeb19.jpg142 KB · Views: 887 -

kitless3-BASHfeb19.jpg145.9 KB · Views: 779

kitless3-BASHfeb19.jpg145.9 KB · Views: 779 -

100_4987.jpg111.5 KB · Views: 1,126

100_4987.jpg111.5 KB · Views: 1,126 -

100_4996.jpg86.3 KB · Views: 774

100_4996.jpg86.3 KB · Views: 774 -

100_5008.jpg73.3 KB · Views: 762

100_5008.jpg73.3 KB · Views: 762