MesquiteMan

Retired Head Moderator

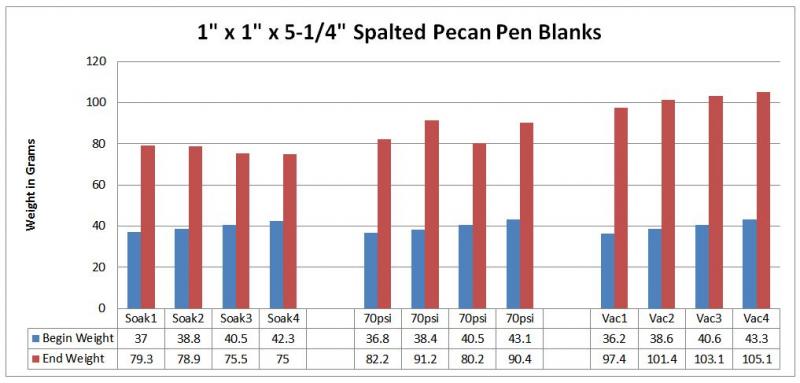

I recently decided to do some testing to see what kind of stabilizing results one could obtain without using vacuum. This test was performed with a thermosetting professional stabilizing resin. I started with 30 1" x 1" x 5-1/4" spalted pecan pen blanks that were air dried. I then placed them in my toaster oven at 200° F for 24 hours to make sure they were as dry as possible. I recorded the weight in grams of each blank before and after placing in the toaster oven and amazingly, from air dry to oven dry, they lost an average of 16% weight! Since weight equals water in this instance, and water occupies cellular space that could be occupied by the resin, it is safe to say that it is a really good practice to oven dry your blanks before stabilizing!

After cooling down to room temperature, I sorted them in groups based on weight and then choose 3 blanks from 4 different groups of weight sorted blanks to create 3 sets of 4 blanks with similar weight distributions between each group.

The first set of 4 blanks were placed in a chamber and weighted down. I then added the stabilizing resin to submerge the blanks and set them aside to soak. I allowed them to soak for 24 hours.

The second set of blanks were placed in a chamber, weighted down, and submerged in the stabilizing resin. This chamber was then placed in my pressure pot and pressurized to 70 psi. I allowed these blanks to remain at 70 psi for 24 hours. The pressure was then released and the blanks were allowed to soak for 1 hour with no pressure.

The final set of blanks were placed in a chamber, weighted down, and submerged in the stabilizing resin. This chamber was then connected to a vacuum pump and pulled down to a 99% vacuum until the bubbles stopped coming out of the blanks. The vacuum was then released and the blanks were allowed to soak for 30 minutes.

After their respective cycles, each blank was removed from the chamber/resin and allowed to drain for 30 minutes. After draining, each blank was wrapped in foil and cured in a pre-heated 200° F toaster oven for 2 hours. Once cured, the blanks were unwrapped and allowed to cool. The excess material that had polymerized on the outside of the blank was scrapped off, being careful to not remove any of the wood. All 16 blanks were then weighed and recorded.

The weight results from each blank were then input into an Excel spreadsheet and the differences and % were calculated as well as an average for each set of blanks. The results are shown on the graphs below.

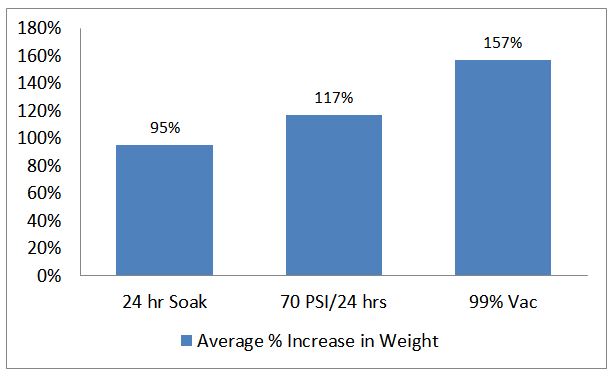

This is the average weight gain from raw to finished blank as a % for each group

One thing that I found very interesting is what happened to the blanks that were placed under pressure. After removing from the pressure and allowing to soak, they continued to bubble for an hour. To me, this proves the principle that pressure may indeed push the resin into the blank by compressing the air inside the blank but once the pressure is removed, the air inside the blank expands and pushes some of the resin back out of the blank. The pressure treated blanks also had the highest amount of cured resin on the outside of the blanks by far which shows that the pressure continued to push the resin out while curing.

These pics are NOT under vacuum!

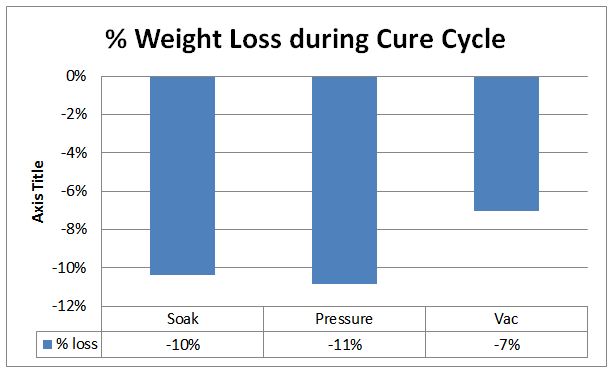

When curing all blanks, some of the resin is going to leak out and polymerize on the outside. For this test, I also recorded the weight right before curing as well as after. The soaked and pressurized blanks lost a significant higher % of their weight after curing. To me, this shows that with vacuum, the atmospheric pressure is keeping more of the resin in the blank.

Here is a chart with the average % weight loss for each group between their respective cycle and cured.

So, based on this testing, I would have to say that yes, you can stabilize blanks by just soaking or with pressure but will get a higher concentration of resin inside the blank, and thus a better stabilized blank if you use vacuum.

Note: This test was done using ordinary shop type equipment. Most of us to not have access to super high pressure as used by some professional stabilizing companies so I am not saying that pressure is not effective, just that, based on this test, for the home shop environment, 70psi is not as effective as a deep vacuum.

After cooling down to room temperature, I sorted them in groups based on weight and then choose 3 blanks from 4 different groups of weight sorted blanks to create 3 sets of 4 blanks with similar weight distributions between each group.

The first set of 4 blanks were placed in a chamber and weighted down. I then added the stabilizing resin to submerge the blanks and set them aside to soak. I allowed them to soak for 24 hours.

The second set of blanks were placed in a chamber, weighted down, and submerged in the stabilizing resin. This chamber was then placed in my pressure pot and pressurized to 70 psi. I allowed these blanks to remain at 70 psi for 24 hours. The pressure was then released and the blanks were allowed to soak for 1 hour with no pressure.

The final set of blanks were placed in a chamber, weighted down, and submerged in the stabilizing resin. This chamber was then connected to a vacuum pump and pulled down to a 99% vacuum until the bubbles stopped coming out of the blanks. The vacuum was then released and the blanks were allowed to soak for 30 minutes.

After their respective cycles, each blank was removed from the chamber/resin and allowed to drain for 30 minutes. After draining, each blank was wrapped in foil and cured in a pre-heated 200° F toaster oven for 2 hours. Once cured, the blanks were unwrapped and allowed to cool. The excess material that had polymerized on the outside of the blank was scrapped off, being careful to not remove any of the wood. All 16 blanks were then weighed and recorded.

The weight results from each blank were then input into an Excel spreadsheet and the differences and % were calculated as well as an average for each set of blanks. The results are shown on the graphs below.

This is the average weight gain from raw to finished blank as a % for each group

One thing that I found very interesting is what happened to the blanks that were placed under pressure. After removing from the pressure and allowing to soak, they continued to bubble for an hour. To me, this proves the principle that pressure may indeed push the resin into the blank by compressing the air inside the blank but once the pressure is removed, the air inside the blank expands and pushes some of the resin back out of the blank. The pressure treated blanks also had the highest amount of cured resin on the outside of the blanks by far which shows that the pressure continued to push the resin out while curing.

These pics are NOT under vacuum!

When curing all blanks, some of the resin is going to leak out and polymerize on the outside. For this test, I also recorded the weight right before curing as well as after. The soaked and pressurized blanks lost a significant higher % of their weight after curing. To me, this shows that with vacuum, the atmospheric pressure is keeping more of the resin in the blank.

Here is a chart with the average % weight loss for each group between their respective cycle and cured.

So, based on this testing, I would have to say that yes, you can stabilize blanks by just soaking or with pressure but will get a higher concentration of resin inside the blank, and thus a better stabilized blank if you use vacuum.

Note: This test was done using ordinary shop type equipment. Most of us to not have access to super high pressure as used by some professional stabilizing companies so I am not saying that pressure is not effective, just that, based on this test, for the home shop environment, 70psi is not as effective as a deep vacuum.

Attachments

Last edited: